Preparation method and use method of urban sewage plant sludge heavy metal stabilizing agent

A technology for heavy metal stabilizer and urban sewage, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of insufficient stability of the existing state, and achieves a simple preparation method without secondary production. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0074] The using method of the above-mentioned prepared urban sewage plant sludge heavy metal stabilizer of the present invention, its preferred embodiment is:

[0075] The stabilization process of heavy metals in municipal sludge includes the following steps:

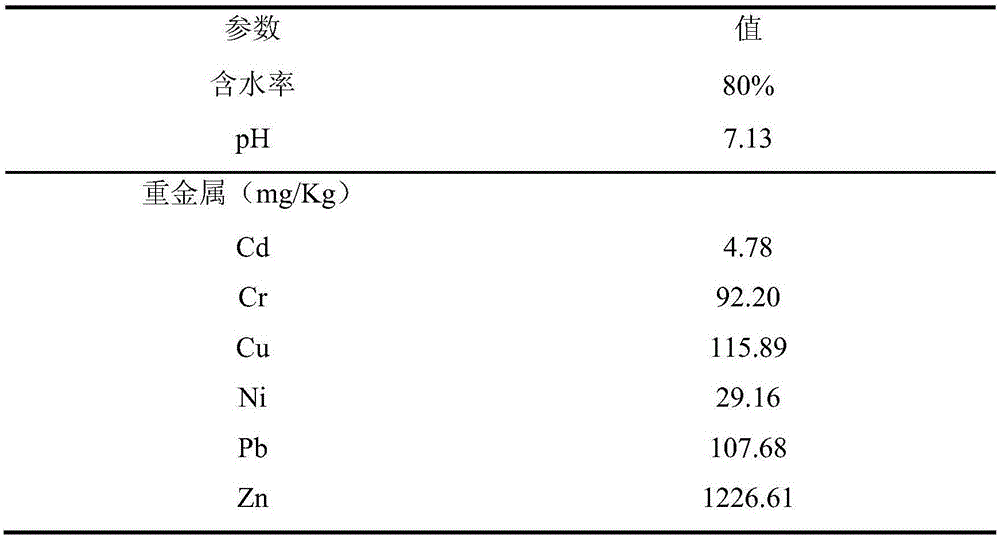

[0076] The dewatered sludge with a water content of about 80% retrieved from the sewage treatment plant is naturally air-dried, and then passed through a 20-mesh sieve;

[0077] Evenly add claim 1 to prepare stabilizer in the sieved sludge, the dosage of stabilizer is 0.25%, 0.5%, 1%, 2% of the sieved sludge amount, and according to water: sludge=1.5: Add deionized water at a ratio of 1, and stir evenly;

[0078] Put the sludge added with the stabilizer for a certain period of time, and stir the sludge regularly during this period;

[0079] Dry and grind the sludge that has been stabilized for a certain period of time.

[0080] After the above stabilizers have been stabilized for a certain period of time, the stabil...

Embodiment 1

[0098] Embodiment 1: preparation of carboxymethyl chitosan grafted thiourea (TCMC)

[0099] Carboxymethylation:

[0100] Suspend 10g chitosan in 100mL isopropanol, add 1mol / L NaOH 252mL under stirring (divided into 6 parts, add 1 part every 20min), continue to stir the lye mixture for 10h, then add 12g of solid chloroacetic acid (divided into 5 parts, Add 1 part every 5min). Then the above mixture was heated to 60°C and reacted for 3h. It was then cooled, and 200 mL of deionized water was added thereto, and the pH value of the system was adjusted to 7 with glacial acetic acid. The obtained solution was subjected to suction filtration, and the suction filtered product was first rinsed with 70% ethanol, and then rinsed with absolute ethanol. After suction filtration, the product was put into an oven at a temperature of 55°C for drying to obtain a carboxymethyl shell polysaccharides.

[0101] Preparation of carboxymethyl chitosan grafted with thiourea

[0102] Dissolve 3g of...

Embodiment 2

[0103] Embodiment 2: grafted thiourea chitosan composite activated carbon (TCTS-AC)

[0104] Weigh 0.5g of chitosan, put it into a beaker, then add 25mL of 5% glacial acetic acid, put the beaker on a magnetic stirrer, and add 0.5g of activated carbon powder to it after it becomes gelatinous. Stir until the charcoal is evenly distributed (about 15 minutes). Then thiourea and glutaraldehyde solution (1.5 g of thiourea and 0.5 mL of 25% glutaraldehyde) reacted at 50° C. for 30 minutes were added into the beaker, and the stirring was continued until no solid precipitated out. The precipitate was repeatedly washed with 0.1mol / L NaOH, distilled water and ethanol, filtered with suction, and dried at 55°C to obtain TCTS-AC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com