Microwave preparation method of alpha-calcium sulfate hemihydrate

A technology of calcium sulfate hemihydrate and calcium sulfate dihydrate, which is applied in the field of preparation of α-calcium sulfate hemihydrate, can solve the problems of multiple impurities, low added value, high free water, etc., and achieve the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 5.0g calcium sulfate dihydrate and 100mL mixed salt solution (calcium chloride 100g / L, sodium chloride 50g / L) into the reaction vessel, put it into the CW-2000 ultrasonic / microwave collaborative extraction / reaction instrument, set the program: Under the combined action of ultrasonic waves and microwaves, the temperature of the reaction system was raised to 105°C at a heating rate of 4°C / min, and then kept at a constant temperature for 2 hours; immediately after the reaction, the reaction mixture was filtered and washed, and the solid product was dried in an oven at 60°C After 19 hours, α-calcium sulfate hemihydrate was obtained.

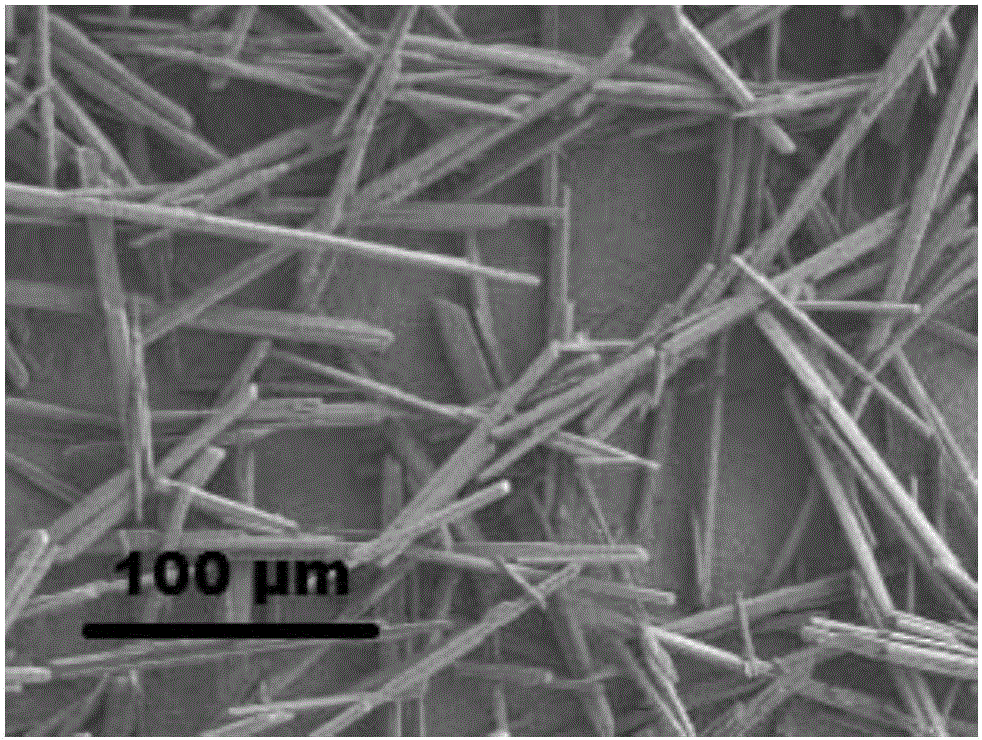

[0030] figure 2 It is the scanning electron micrograph of the prepared α-calcium sulfate hemihydrate, by figure 2 It can be seen that the prepared α-calcium sulfate hemihydrate has a uniform fibrous structure with an average length of 112.9 μm and an average diameter of 7.37 μm.

Embodiment 2

[0032] Add 5.0g calcium sulfate dihydrate and 100mL mixed salt solution (calcium chloride 100g / L, sodium chloride 50g / L) into the reaction vessel, put it into the CW-2000 ultrasonic / microwave collaborative extraction / reaction instrument, set the program: Under the combined action of ultrasonic waves and microwaves, the temperature of the reaction system was raised to 105°C at a heating rate of 8°C / min, and then kept at a constant temperature for 3 hours; immediately after the reaction, the reaction mixture was filtered and washed, and the solid product was placed in an oven at 60°C Dry for 12 hours to obtain α-calcium sulfate hemihydrate.

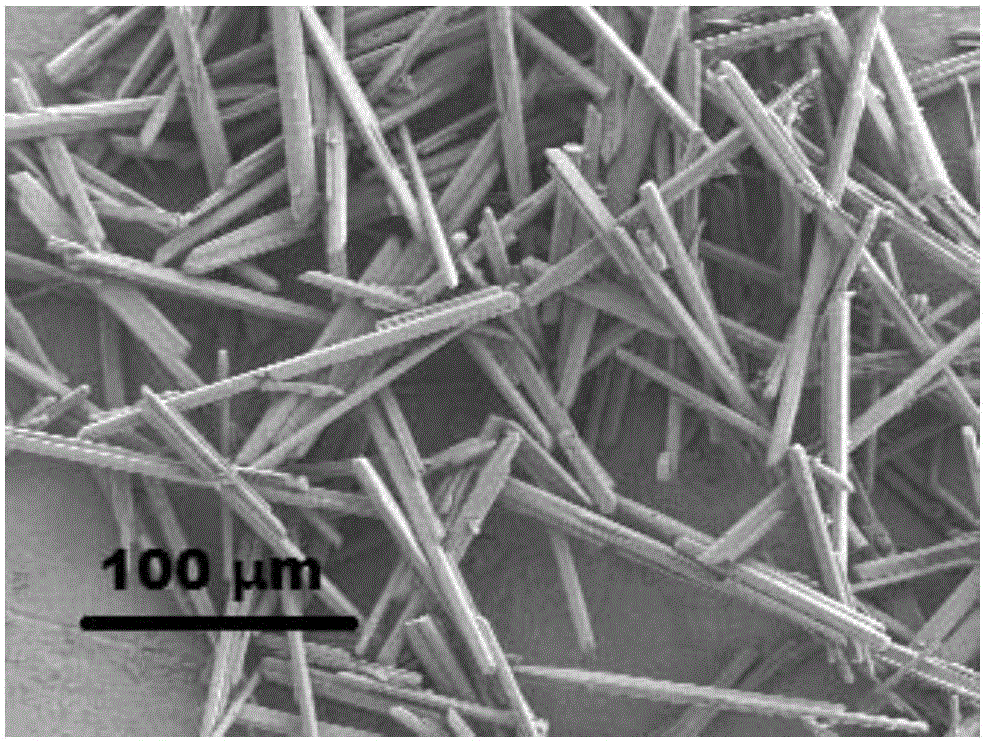

[0033] image 3 is the scanning electron micrograph of the prepared α-calcium sulfate hemihydrate, by image 3 It can be seen that the prepared α-calcium sulfate hemihydrate has a uniform fibrous structure with an average length of 113.78 μm and an average diameter of 8.31 μm.

[0034] Figure 4 is the XRD pattern of the prepared α-calcium...

Embodiment 3

[0040] Add 8.0g calcium sulfate dihydrate and 100mL mixed salt solution (calcium chloride 80g / L, sodium chloride 50g / L) into the reaction vessel, put it into the CW-2000 ultrasonic / microwave collaborative extraction / reaction instrument, set the program: Under the combined action of ultrasonic waves and microwaves, the temperature of the reaction system was raised to 105°C at a heating rate of 2°C / min, and then kept at a constant temperature for 3 hours; immediately after the reaction, the reaction mixture was filtered and washed, and the solid product was placed in an oven at 60°C Dry for 18 hours to obtain α-calcium sulfate hemihydrate. The crystal morphology of the obtained α-calcium sulfate hemihydrate was a uniform fibrous structure, the average crystal length was 110.78 μm, and the average diameter was 7.31 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com