Fertilizer synergist containing amino acid and preparation method of fertilizer synergist

A fertilizer synergist and amino acid technology, applied in organic fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of increased agricultural input costs, unreasonable fertilizer application, and low nutrient utilization rate, and achieve stable and long-term effects. Improve crop quality and yield, regulate crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

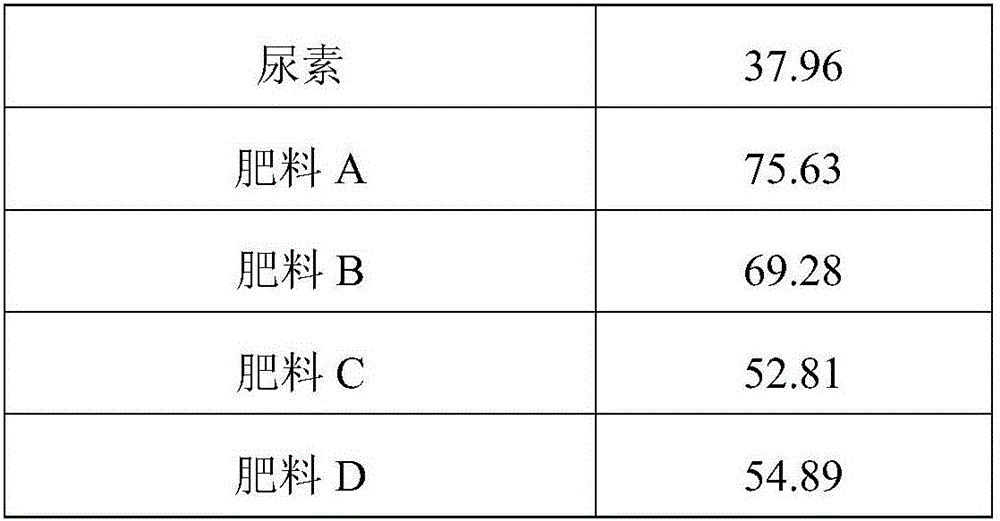

Examples

Embodiment 1

[0027] 1) brown coal is crushed to 100 mesh;

[0028] 2) Add 1 kg of lignite and 10 kg of water into the reactor, stir evenly at a stirring rate of 150 r / min, add 100 g of 0.2% sodium hydroxide solution and continue stirring; then add 1 kg of mixed amino acids and 20 g of zinc methionine and stir for 0.5 h; the mixing The amino acid is a mixture of glycine, alanine and leucine solutions, the mixing ratio is 1:0.6:0.2 by weight, and the concentration of the amino acid solution is 50%;

[0029] 3) Filter the above mixture for 2 times. The filter adopts a CT bucket plate and frame filter produced by Haining Zhengxing Special Filter Equipment Manufacturing Co., Ltd., then heat the supernatant to 110°C for 3 hours, and concentrate until the solid content is 12%.

Embodiment 2

[0031] 1) crush the weathered coal to 120 mesh;

[0032] 2) Add 1 kg of weathered coal and 20 kg of water into the reactor; stir evenly at a stirring rate of 100 r / min, add 200 g of 0.3% sodium hydroxide solution and continue stirring; then add 2 kg of mixed amino acids and 20 g of zinc methionine and stir for 0.5 h; The mixed amino acid is a mixture of glycine, alanine and leucine solutions, and the mixing ratio is 1:0.5:0.5 by weight; the concentration of the amino acid solution is 60%;

[0033] 3) Filter the above mixture for 2 times. The filter adopts a CT barrel plate and frame filter produced by Haining Zhengxing Special Filter Equipment Manufacturing Co., Ltd., and then heat the supernatant to 120° C. for 3 hours, and concentrate until the solid content is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com