Ethyl trifluoroacetate preparation method

A technology of ethyl trifluoroacetate and trifluoroacetic acid, which is applied in the field of preparation of ethyl trifluoroacetate, can solve the problems of not being able to directly obtain pure ethyl trifluoroacetate, and achieve easy industrial production, mild conditions and low raw material cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

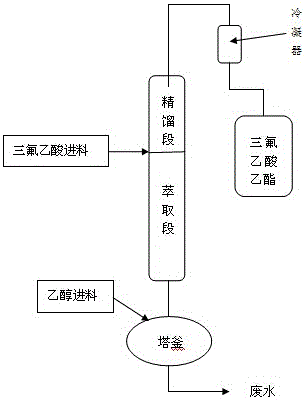

[0019] The 2000L reactor is equipped with a 12-meter rectification tower, which is divided into a 6-meter extraction section, a 6-meter rectification section, and a 16-meter distillation section. 2 enamel condenser. A solid superacid is used as a catalyst.

[0020] Add 500Kg ethyl trifluoroacetate to the reaction kettle in advance, and then raise the temperature to reflux. After the components in the rectification tower are stable, start to add trifluoroacetic acid from the top of the extraction section at a rate of 100kg / h. , began to add absolute ethanol to the reactor at a rate of 40kg / h, and after 10 minutes of total reflux, the temperature at the top of the column was stable at 61°C, and began to extract ethyl trifluoroacetate at a rate of 125kg / h.

[0021] After 10 hours, the feed and extraction were stopped. After the reactor cooled down, the materials in the reactor were left to stand for stratification, and the organic layer in the reactor and the obtained pure ethyl...

Embodiment 2

[0023] The 2000L reactor is equipped with a rectification tower with a diameter of 200mm and a height of 12 meters, which is divided into a 6-meter extraction section, a 6-meter distillation section, and a 16-meter distillation section. 2 enamel condenser. Concentrated sulfuric acid is used as catalyst.

[0024] Under cooling conditions, slowly add 150kg of concentrated sulfuric acid to 1000kg of trifluoroacetic acid in advance, mix well and pump the trifluoroacetic acid into the high level tank. Add 500Kg ethyl trifluoroacetate in the reaction kettle, then raise the temperature and reflux, after the components in the rectifying tower are stabilized, start to add trifluoroacetic acid from the top of the extraction section at a rate of 115kg / h, while adding trifluoroacetic acid, Start to add dehydrated ethanol to the reaction kettle at a rate of 40kg / h. After 10 minutes of total reflux, the temperature at the top of the column is stable at 61°C, and start to extract ethyl trif...

Embodiment 3

[0027] 2000L reactor, equipped with a rectification tower with a diameter of 200mm and a height of 15 meters, which is divided into a 7-meter extraction section, an 8-meter rectification section, and a 20m 2 enamel condenser. Concentrated sulfuric acid is used as catalyst.

[0028] Under cooling conditions, slowly add 150kg of concentrated sulfuric acid to 1000kg of trifluoroacetic acid in advance, mix well and pump the trifluoroacetic acid into the high level tank. Add 400Kg of trifluoroacetic acid, 80kg of concentrated sulfuric acid, and 161.5kg of absolute ethanol into the reaction kettle, and then raise the temperature and reflux for 30 minutes. After the components in the rectification tower are stabilized, start adding three Fluoroacetic acid, while adding trifluoroacetic acid, began to add absolute ethanol to the reaction kettle at a rate of 40kg / h. After 10 minutes of total reflux, the temperature at the top of the tower was stable at 61°C, and began to extract triflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com