Amido polymer filtrate loss reducer for water-based drilling fluid resistant to high temperature, salt and calcium and preparation method and application thereof

A technology of amine-based polymer and water-based drilling fluid, which is applied in the field of drilling fluid, can solve the problems of difficult addition of amine-based polymer fluid loss control agent, increased shear force of drilling fluid viscosity, and large fluctuations in rheological properties of drilling fluid. Achieve the effect of enhancing steric stability and inhibiting coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

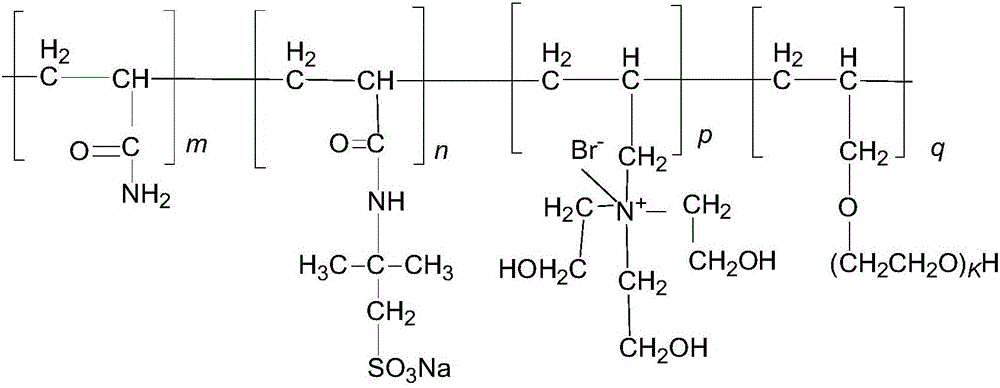

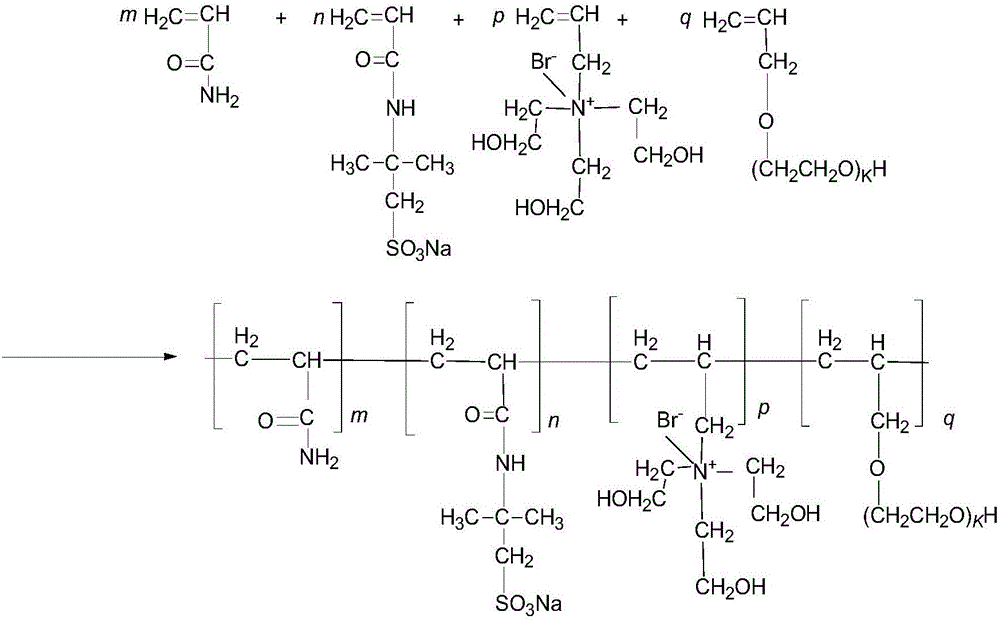

[0028] An amine-based polymer fluid loss reducer for high-temperature and anti-salt-calcium water-based drilling fluids, composed of acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, allyl polyethylene glycol, triethylene glycol The mole of acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, allyl polyethylene glycol, trihydroxyethyl allyl ammonium bromide The ratio is 8.1~20.2:9~15.2:2.1~4.3:8~10, and the reaction formula is:

[0029]

[0030] Wherein, m=40%~45%, n=40%~45%, p=1-m-n-q, q=8%~10%, and the molecular weight of allyl polyethylene glycol is between 400~1000, K 9 to 20, m, n, p, q represent mole percentage.

[0031] The preparation method of the amine-based polymer fluid loss reducer comprises the following steps: press acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, allyl polyethylene glycol, trihydroxyethylallyl bromide The molar ratio of ammonium chloride is 8.1~20.2:9~15.2:2.1~4.3:8~10 Weigh the monomer raw material; dissolve 2-acrylamido-2-me...

Embodiment 2

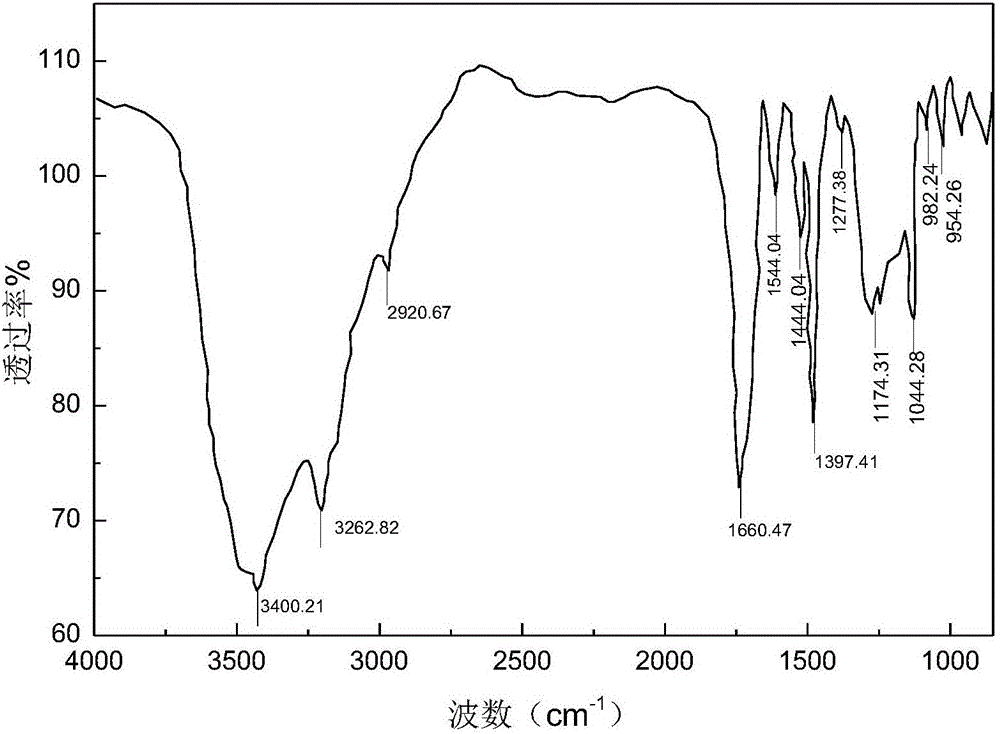

[0032] Structural characterization of the amino polymer fluid loss control agent obtained in Example 2

[0033] Depend on figure 1 It can be seen that 1044.28cm -1 for-SO 3- The characteristic absorption peak of , indicating that the molecular structure of the polymer product contains sulfonic acid groups; 2920.67cm -1 for CH 2 The bending vibration absorption peak of the group; 1660.47cm -1 It is the C=O stretching vibration absorption peak of amide group; 1544.04cm -1 It is the N-H bond bending vibration and C-N bond stretching vibration absorption peak in the secondary amide -CONH- group; 1397.41cm -1 at -CH 3 The characteristic absorption peak; 1277.38cm -1 At the C-N stretching vibration absorption peak; 982.24cm -1 where RCH=CH 2 Middle = C-H bending vibration peak; 3400.21cm -1 It is the non-associated N-H contraction vibration absorption peak; 1174.31cm -1 There is a characteristic absorption peak at , indicating that the product molecule contains etheroxy g...

Embodiment 3

[0034] Aqueous solution performance research of the amino polymer fluid loss reducer obtained in embodiment 3

[0035] Table 1: Rheology of Amine-Based Polymer Fluid Loss Control Agents

[0036] Addition amount of fluid loss control agent (wt%) 0.5 1.0 1.5 2 Apparent viscosity (mPa·s) 2.5 4.5 7.0 8.5 Plastic viscosity (mPa·s) 2.0 4.0 6.5 8.5

[0037] It can be seen from Table 1 that the viscosity of the polymer solution gradually increases with the increase in the amount of fluid loss control agent added. When the solution concentration is 2%, its apparent viscosity and plastic viscosity are only 8.5mPa·s, which shows that the viscosity enhancing effect of fluid loss control agent is limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com