Thermal shock resistant high-refraction LED packaging glue composition and preparation method thereof

A technology of LED packaging and thermal shock resistance, applied in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problem of poor compatibility, low penetration rate of LED packaging adhesive, and low reactivity and other problems, to achieve the effect of excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

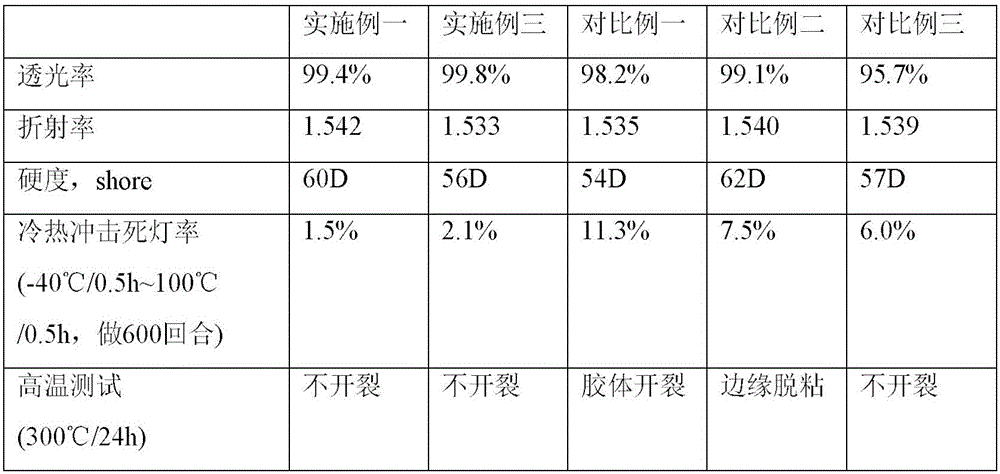

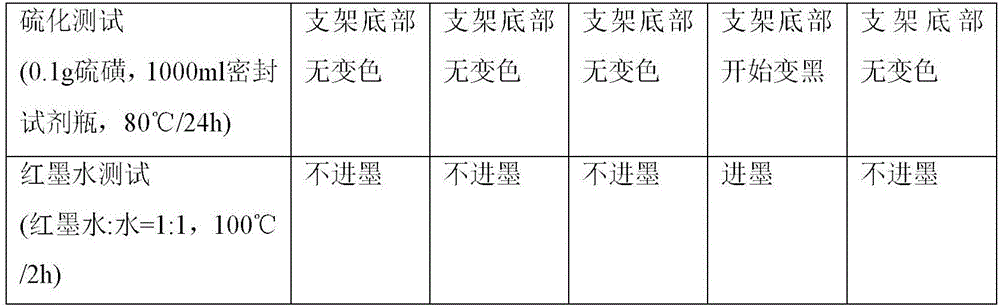

[0033] Example 1 High refraction LED encapsulation adhesive composition

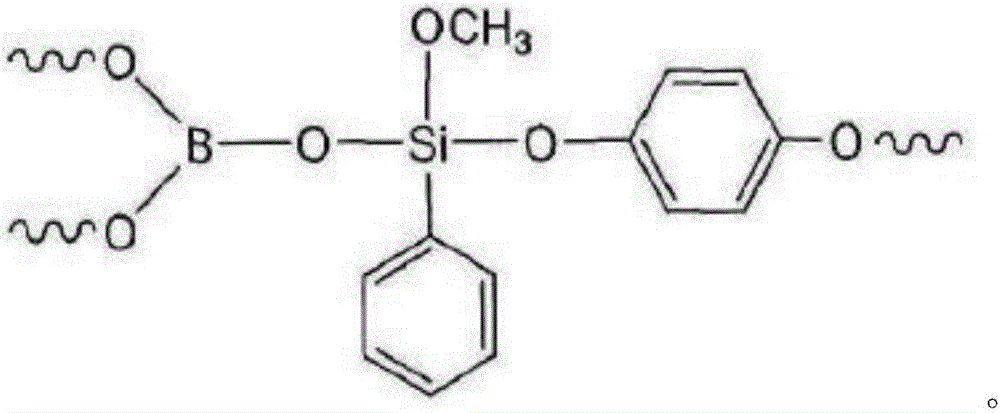

[0034] High refraction LED encapsulation adhesive composition, composed of A component and B component with a weight ratio of 1:1; A component includes the following components and their parts by weight: 30 parts of methyl phenyl vinyl silicone resin, formaldehyde 15 parts of phenylvinyl silicone oil, 0.2 parts of 1,3-dimethyl-1,3-diphenyl-1,3-divinylsiloxane platinum complex, and 0.02 parts of iron-containing alazane complex ; Component B includes the following components and parts by weight: 10 parts of methylphenyl vinyl resin, 35 parts of methylphenyl hydrogen-containing resin, 0.05 parts of 3-methyl-1-pentyn-3-alcohol 1 part, 1 part of borosiloxane oligomer.

[0035] The preparation method includes the following steps: Preparation of component A: Weigh methylphenylvinyl silicone resin and methylphenylvinyl silicone oil in a reaction vessel, stir evenly, add heat-resistant agent and catalyst, stir e...

Embodiment 2

[0036] Embodiment 2 High refraction LED encapsulation adhesive composition

[0037] A high-refractive LED encapsulation adhesive composition is composed of component A and component B in a weight ratio of 1:1; component A includes the following components and their parts by weight: 32 parts of methylphenylvinyl silicone resin, 18 parts of phenylvinyl silicone oil, 0.3 parts of platinum complex of 1,3-dimethyl-1,3-diphenyl-1,3-divinylsiloxane, 0.02 parts of iron-containing silazane complex ; B component includes the following components and parts by weight: 12 parts of methylphenyl vinyl silicone resin, 40 parts of methylphenyl hydrogen-containing silicone resin, 0.08 parts of 3-methyl-1-pentyn-3-alcohol Parts, 1.5 parts of borosiloxane oligomer.

[0038] The preparation method is the same as in Example 1.

Embodiment 3

[0039] Embodiment three high refraction LED encapsulation adhesive composition

[0040] High refraction LED encapsulation adhesive composition, composed of A component and B component with a weight ratio of 1:1; A component includes the following components and their parts by weight: 28 parts of methylphenyl vinyl silicone resin, 14 parts of phenylvinyl silicone oil, 0.2 part of platinum complex of 1,3-dimethyl-1,3-diphenyl-1,3-divinylsiloxane, 0.01 part of iron-containing azane complex ; B component includes the following components and parts by weight: 8 parts of methylphenyl vinyl silicone resin, 32 parts of methylphenyl hydrogen-containing silicone resin, 0.03 parts of 3-methyl-1-pentyn-3-ol 1 part, 1 part of borosiloxane oligomer.

[0041] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com