Three-dimensional infrared detector pixel structure and preparation method therefor

An infrared detector and infrared detection technology, applied in the direction of resistors, resistance manufacturing, electrical components, etc., can solve the problems of low sensitivity, expensive materials, complex detection process, etc., achieve flexible setting positions, increase integration density, The effect of increasing the fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The following is attached Figures 1a-8c The present invention will be described in further detail with specific examples. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0061] It should be noted that, in this embodiment, the surface of the silicon substrate also has a reflection area, the reflection area is located below the infrared detection structure, and there is a dielectric layer between the reflection area and the conductive metal area; the interconnection layer is connected to the external circuit. The infrared detection structure adopts the micro bridge structure. The conductive layer is a conductive metal layer.

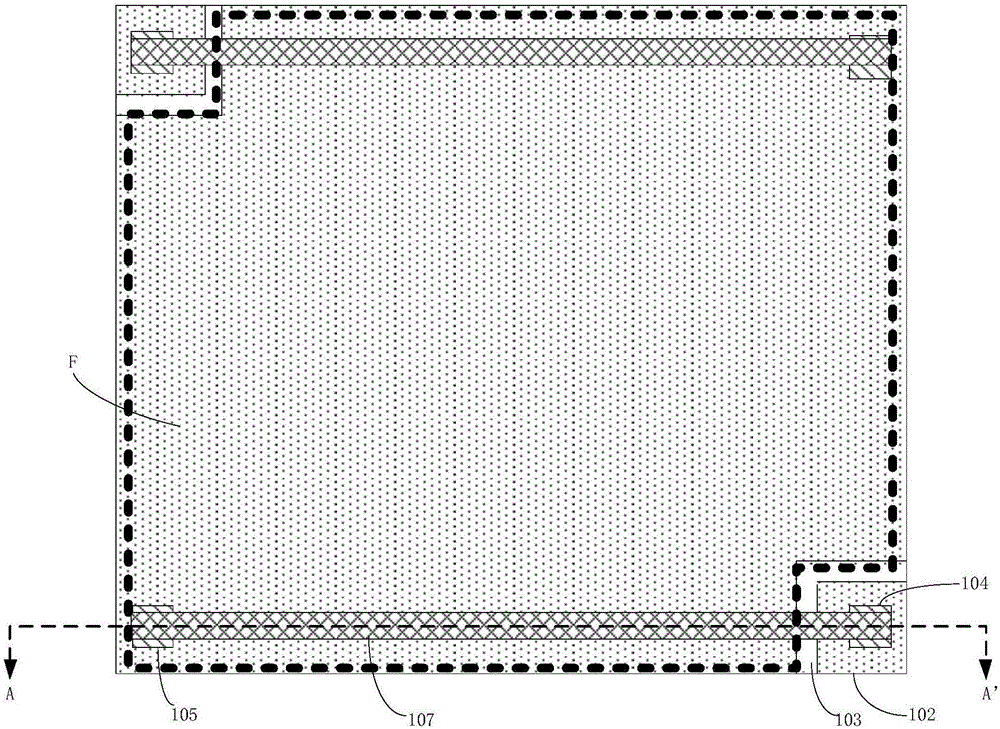

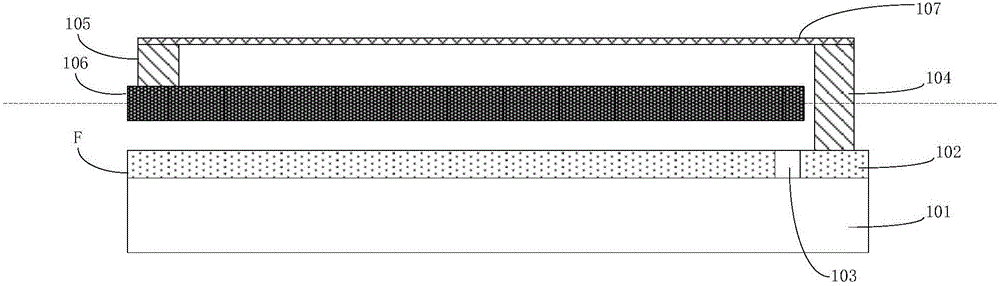

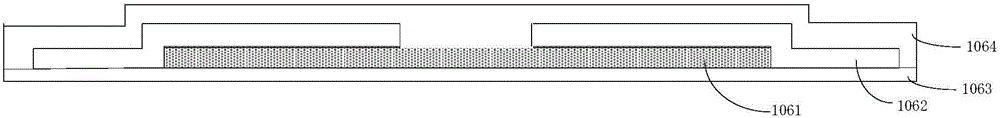

[0062] For this example, see Figure 1a with Figure 1b , Figure 1b for along Figure 1a Schematic diagram of the cross-sectional structure of AA', Figure 1a In the figure, for th...

Embodiment 2

[0092] The following is attached Figure 8a-14 The present invention will be described in further detail with specific examples. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0093] For this example, see Figure 9a with Figure 9b , Figure 9b for along Figure 9a Schematic diagram of the cross-sectional structure of the middle BB', Figure 9aIn the figure, for the sake of convenience, the micro-bridge structure is removed, and the area occupied by the micro-bridge structure is represented by a thick dotted line frame. The infrared detector pixel structure is located on a silicon substrate 201, and the silicon substrate 201 has an interconnection layer (not shown) shown), the surface of the silicon substrate 201 has a conductive metal region 202 electrically connected to the interconnection layer, a reflecti...

Embodiment 3

[0115] The following is attached Figures 15a-21 The present invention will be described in further detail with specific examples. It should be noted that the drawings are all in a very simplified form, using imprecise scales, and are only used to facilitate and clearly achieve the purpose of assisting in describing the present embodiment.

[0116] For this example, see Figure 15a with Figure 15b , Figure 15b for along Figure 15a Schematic diagram of CC' section structure, Figure 15a In , for the convenience of representation, the micro-bridge structure is removed, and the area occupied by the micro-bridge structure is indicated by a thick dotted line frame. The infrared detector pixel structure is located on a silicon substrate 301, which has an interconnection layer, and the silicon substrate 301 has an interconnection layer. The surface of the substrate 301 has a conductive metal region 302 electrically connected to the interconnection layer, a reflective region 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com