Si/TiOx heterojunction-based double-sided crystalline silicon solar cell

A technology of solar cells and crystalline silicon, which is applied in the field of solar cells and semiconductor devices, can solve problems such as hindering the development of HIT solar cells and waste of production equipment, and achieve the effects of reducing photovoltaic power generation costs, increasing power generation, and enhancing built-in electric fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

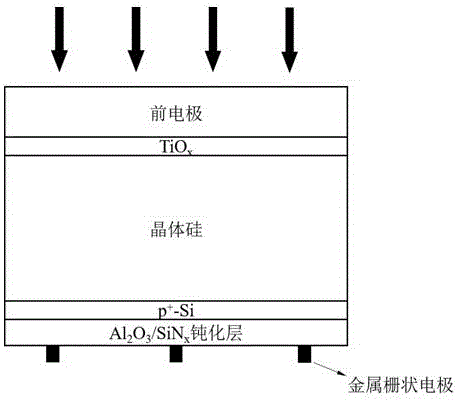

[0019] (1) Use n-type silicon wafers as the absorbing layer, conduct preliminary cleaning on the silicon wafers, and make texture on both sides.

[0020] (2) Prepare a p-type heavily doped layer on the back of the silicon wafer using a diffusion process.

[0021] (3) Deposit Al on the back 2 o 3 passivation layer, followed by grid-shaped Ag electrodes.

[0022] (4) Perform secondary cleaning on the front side of the silicon wafer.

[0023] (5) Preparation of TiO on the front side of the silicon wafer using atomic layer deposition x Floor.

[0024] (6) on TiO x An ITO transparent conductive layer and an Ag metal grid line are deposited on the layer to prepare a front electrode.

Embodiment 2

[0026] (1) Use p-type silicon wafers as the absorbing layer, conduct preliminary cleaning on the silicon wafers, and make texture on both sides.

[0027] (2) The p-type heavily doped layer on the back is prepared by ion implantation process.

[0028] (3) Deposit Al on the back 2 o 3 / SiN x passivation layer, followed by the fabrication of grid-like Cu electrodes.

[0029] (4) Perform secondary cleaning on the front side of the silicon wafer.

[0030] (5) Preparation of TiO by chemical vapor deposition on the front side of the silicon wafer x Floor.

[0031] (6) on TiO x An ITO transparent conductive layer and an Ag metal grid line are deposited on the layer to prepare a front electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com