Resistive random access memory based on MoS2 quantum dot embedded organic polymer and preparation method of resistive random access memory

A technology of resistive memory and quantum dots, applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effect of strong repeatability, novel material system, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

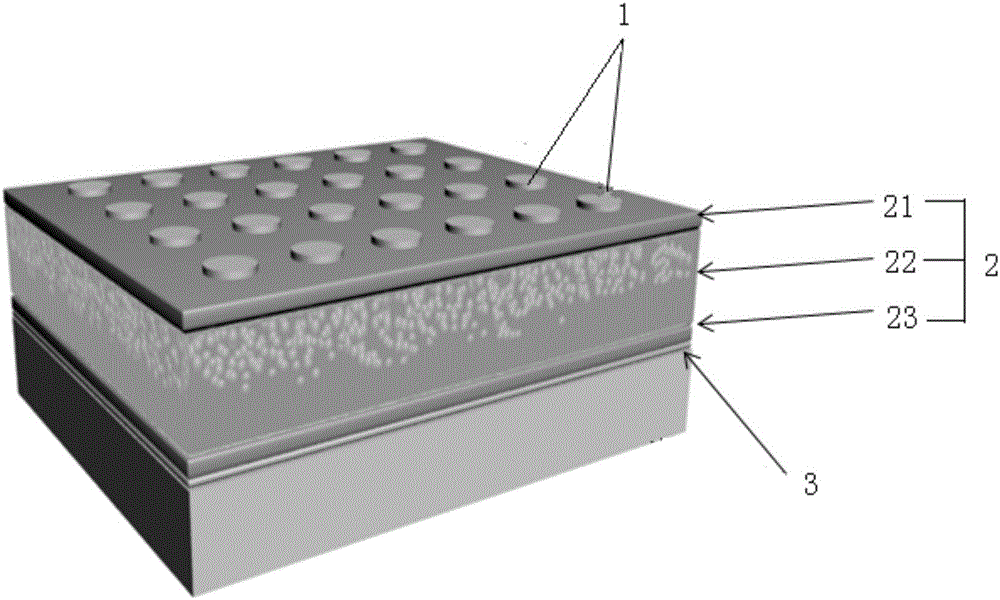

[0047] The present invention provides a MoS-based 2 The resistive variable memory with quantum dots embedded in organic polymers, its structure diagram can be found in figure 1 . The resistive variable memory includes a bottom electrode 3 , a top electrode 1 , and a resistive variable function composite layer 2 sandwiched between the bottom electrode 3 and the top electrode 1 . Wherein the resistive function composite layer 2 comprises a first organic polymer film layer 23, a second organic polymer film layer 21, and MoS sandwiched between the first organic polymer film layer 23 and the second organic polymer film layer 21 2 Quantum dot / organic polymer composite film layer 22 . The bottom electrode 3 and the top electrode 1 are stacked and connected to the first organic polymer film layer 23 and the second organic polymer film layer 21 respectively. As a specific implementation, the bottom electrode 3 can be at least one of conductive films such as ITO, AZO, and FTO, and th...

Embodiment 2

[0050] Based on MoS in Example 1 2 The resistive variable memory with quantum dots embedded in organic polymers can be prepared by referring to the method of this embodiment, and the entire preparation process of the embodiment is carried out in air at room temperature.

[0051] The preparation method comprises the following steps:

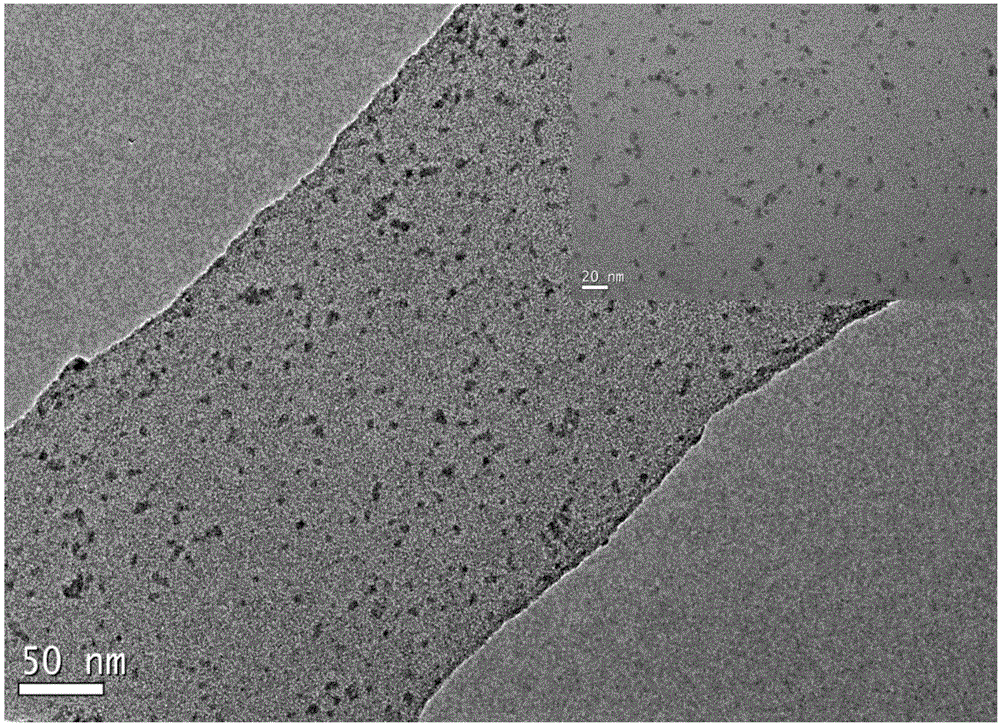

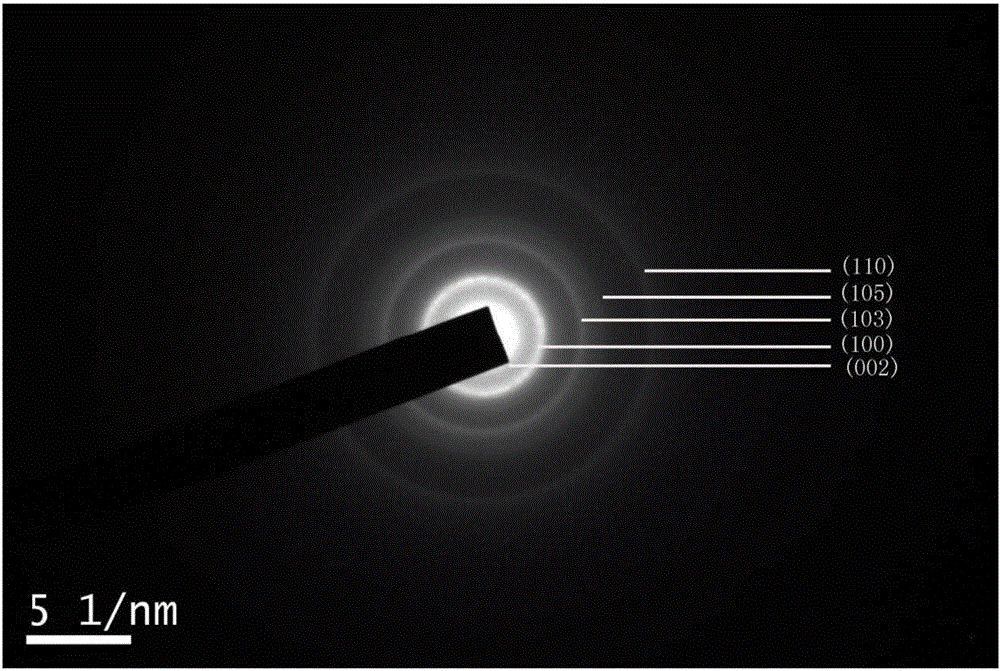

[0052] 1) MoS 2 The powder was added to DMF to form a mixed solution with a concentration of 2 g / L. After ultrasonic mixing for 4 hours, it was added to the reactor, and the solvothermal reaction was performed at a temperature of 200 ° C for 8 hours. After the reactor was naturally cooled, the liquid in the reactor was taken out and allowed to stand for 24 hours. Take 1 / 3 of the supernatant for centrifugation at a speed of 6000-10000r / min, and then take 1 / 3 of the supernatant to obtain MoS 2 DMF solution of quantum dots;

[0053] 2) Add 60 mg of PMMA powder to 1.94 g of THF and ultrasonically mix for 4 hours to obtain a PMMA solution;

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com