Glass substrate, method for producing glass substrate and black matrix substrate

A technology for a glass substrate and a manufacturing method, applied in the field of black matrix substrates, can solve problems such as BM film peeling, and achieve the effects of good adhesion, easy peeling, and peeling prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1

[0071] The surface of the glass substrate was polished as follows. As the glass substrate, a glass substrate for LCD (manufactured by Asahi Glass Co., Ltd., trade name: AN100) made of aluminoborosilicate glass was used. Then, the surface of the glass substrate was polished using a polishing pad using a slurry polishing agent (manufactured by Showa Denko Co., Ltd., trade name: SHOROX A10) containing cerium oxide particles with an average particle diameter of 0.8 to 1.0 μm.

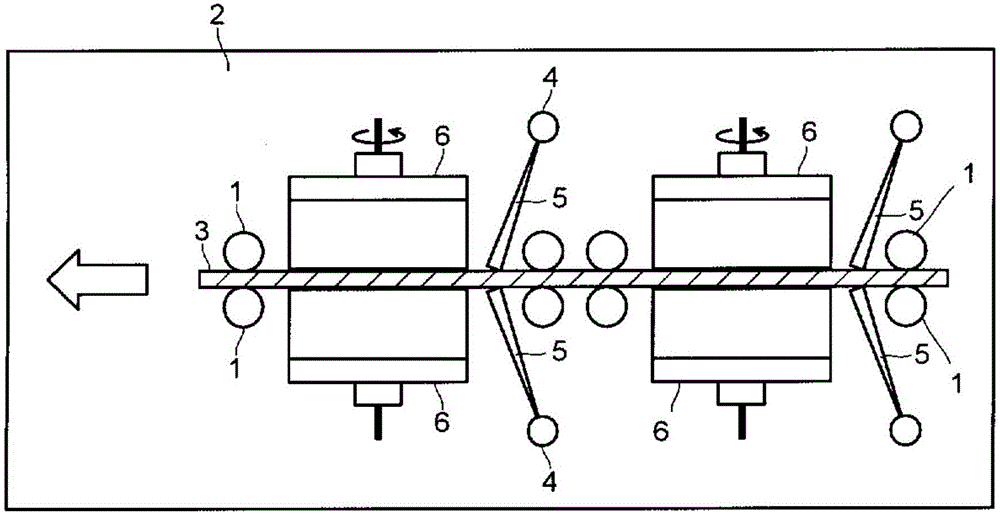

[0072] Then, use figure 1 The cleaning method shown is for cleaning glass substrates whose surfaces have been ground.

Embodiment 1

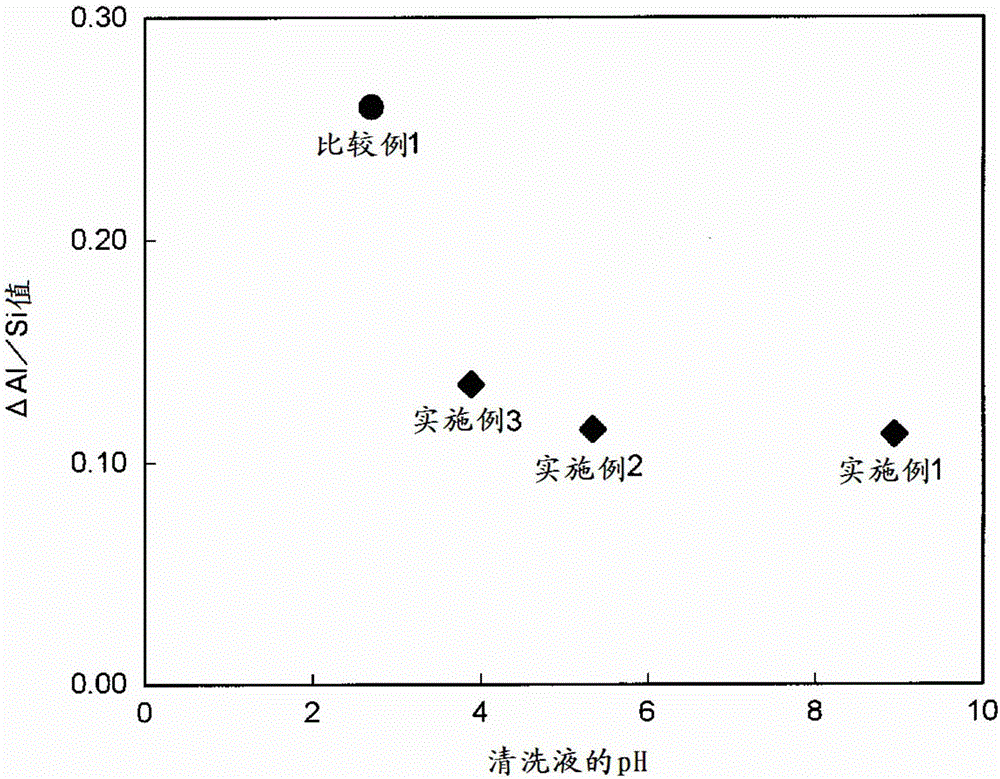

[0073] In Example 1, an alkaline cleaning agent stock solution (manufactured by Parker Corporation, trade name: PK-LCG28) diluted with water to pH 8.9 was used as an aqueous cleaning solution.

[0074] In addition, in Example 2 and Example 3, the liquid which diluted the acidic cleaning agent stock solution with water so that pH may be 5.3 (Example 2) and 3.9 (Example 3), respectively, was used as an aqueous cleaning solution. In addition, the acidic cleaning agent stock solution made PK-LCG492A (trade name of the acidic cleaning agent stock solution manufactured by Parker Corporation) so that the concentration of the organic phosphonic acid in a liquid may be 1 / 4 liquid.

[0075] Furthermore, in Comparative Example 1, a solution obtained by diluting an acidic cleaning agent stock solution (manufactured by Parker Corporation, trade name: PK-LCG492A) with water to pH 2.7 was used as an aqueous cleaning solution.

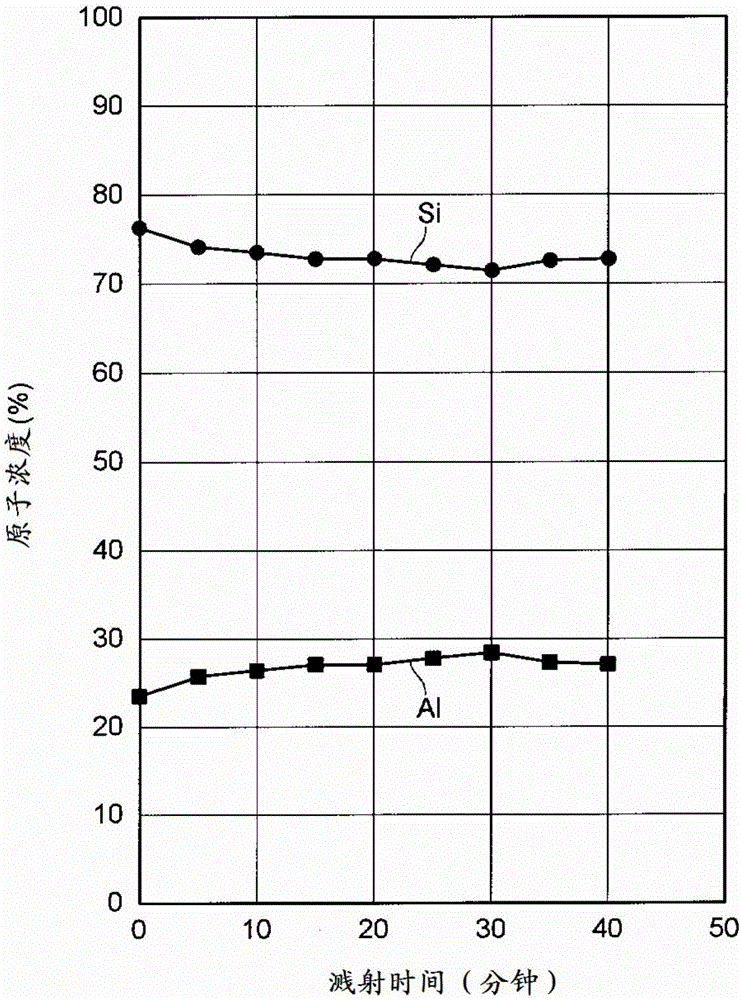

[0076] Then, in Examples 1 to 3 and Comparative Example 1, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com