Pyrylomethoxypolyethylene glycol, its preparation method and method for preparing pyrylopolyethylene glycol-based graphene dispersion liquid

A technology of methoxypolyethylene glycol and graphene dispersion liquid, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., and can solve difficult chemical reactions of other substances, difficulty in research and application, and difficulty in dispersing, etc. problems, to achieve the effect of simple preparation process, low cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

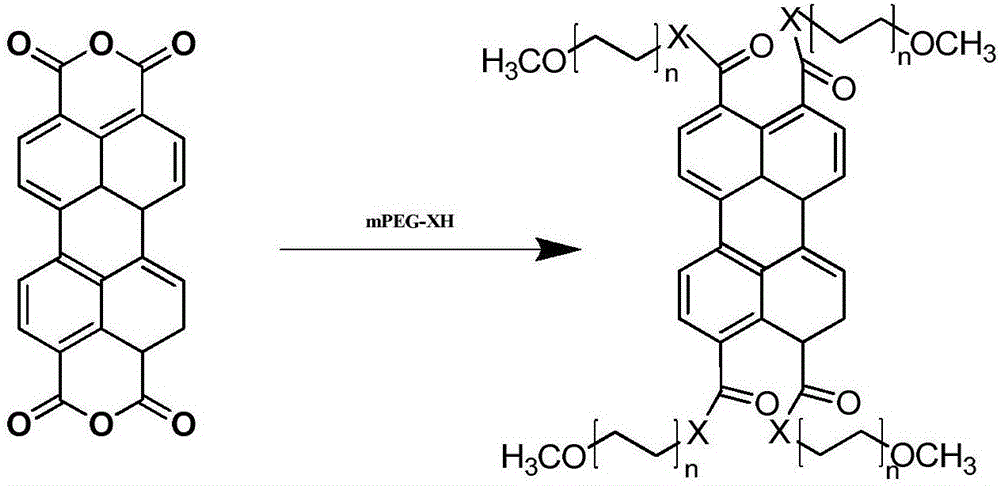

[0040] Add the reaction solvent DMF into the reaction vessel, weigh 0.8g of 3,4,9,10-perylenetetracarboxylic dianhydride, 1.0g of methoxy hydroxyl-terminated polyethylene glycol (average molecular weight Mn=1000), 1.0g of triethylamine 200 microliters, adjust the oil bath temperature to 70°C, and react for 8 hours. After treatment, a multi-armed amphiphilic polymer perylene methoxypolyethylene glycol can be obtained;

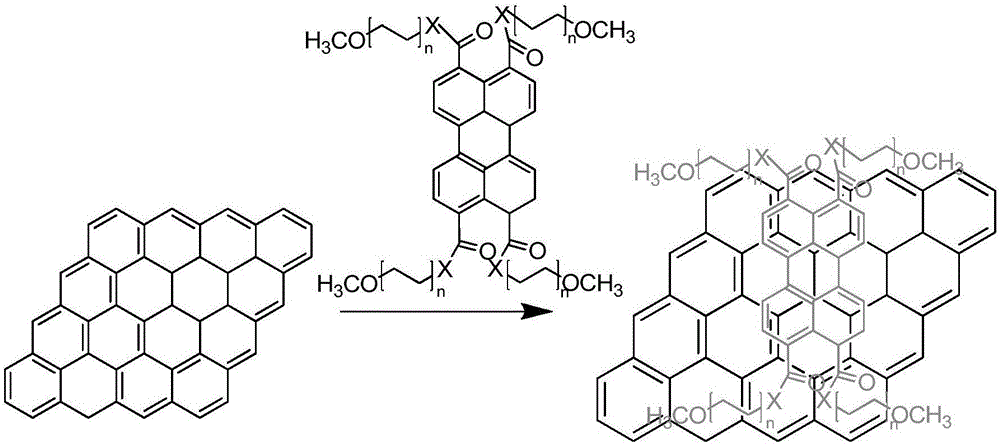

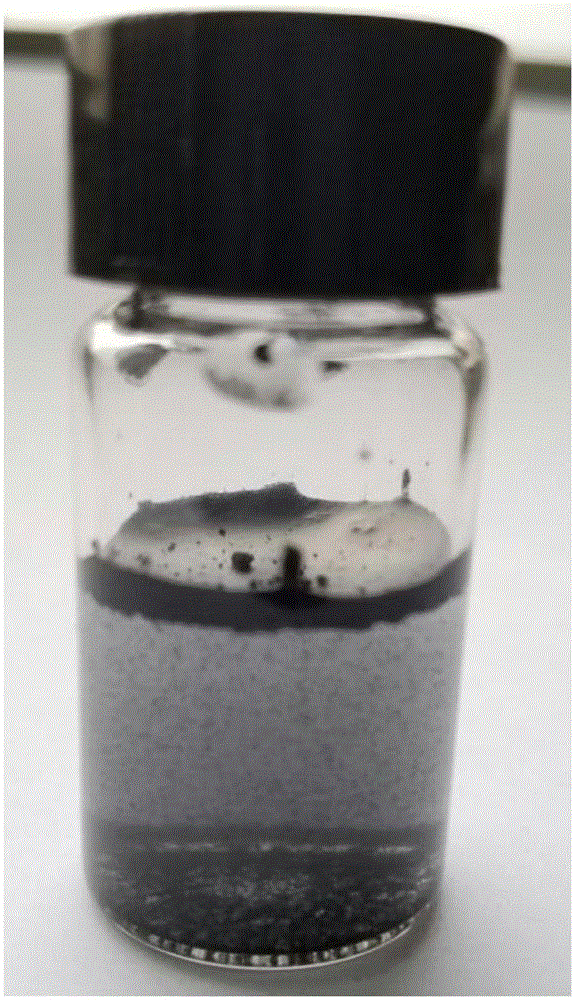

[0041] Add 1 g of this multi-armed amphiphilic polymer and 2 g of graphene powder into water, and after ultrasonication for 1 hour, add water to dilute until the mass content of graphene powder is 0.2% to obtain a stably dispersed graphene solution.

Embodiment 2

[0043] Add the reaction solvent DMF into the reaction vessel, weigh 0.8g of 3,4,9,10-perylenetetracarboxylic dianhydride, 0.5g of methoxy hydroxyl-terminated polyethylene glycol (average molecular weight Mn=500), 0.5g of triethylamine 200 microliters, adjust the temperature of the oil bath to 60°C, and react for 8 hours. After the treatment, the multi-armed amphiphilic polymer perylene methoxypolyethylene glycol can be obtained;

[0044] Add 1 g of this multi-armed amphiphilic polymer and 1 g of graphene powder into water, and after ultrasonication for 1 hour, dilute with water until the mass content of graphene powder is 0.05% to obtain a stably dispersed graphene solution.

Embodiment 3

[0046] Add the reaction solvent DMF into the reaction vessel, weigh 0.8 g of 3,4,9,10-perylenetetracarboxylic dianhydride, 3 g of methoxyl hydroxyl-terminated polyethylene glycol (average molecular weight Mn=3000), 200 g of triethylamine microliter, adjust the temperature of the oil bath to 80°C, and react for 10 hours. After the treatment, the multi-armed amphiphilic polymer perylene methoxypolyethylene glycol can be obtained;

[0047] Add 1 g of this multi-armed amphiphilic polymer and 5 g of graphene powder into water, and after ultrasonication for 1 hour, add water to dilute until the mass content of graphene powder is 0.3% to obtain a stably dispersed graphene solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com