A fluorescent dye dispersion, a spontaneous-emission photosensitive resin composition and a preparation method thereof, a color conversion color filter and a display device including the same

A fluorescent dye, color conversion technology, applied in optomechanical equipment, photosensitive materials for optomechanical equipment, organic dyes, etc., can solve problems such as difficulty in using dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

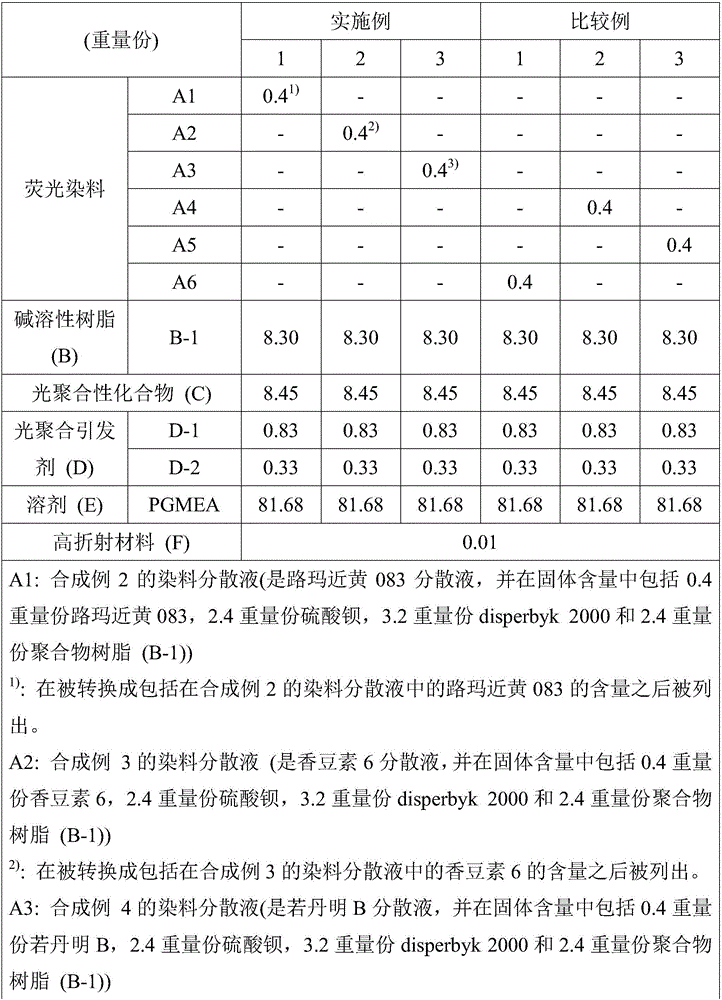

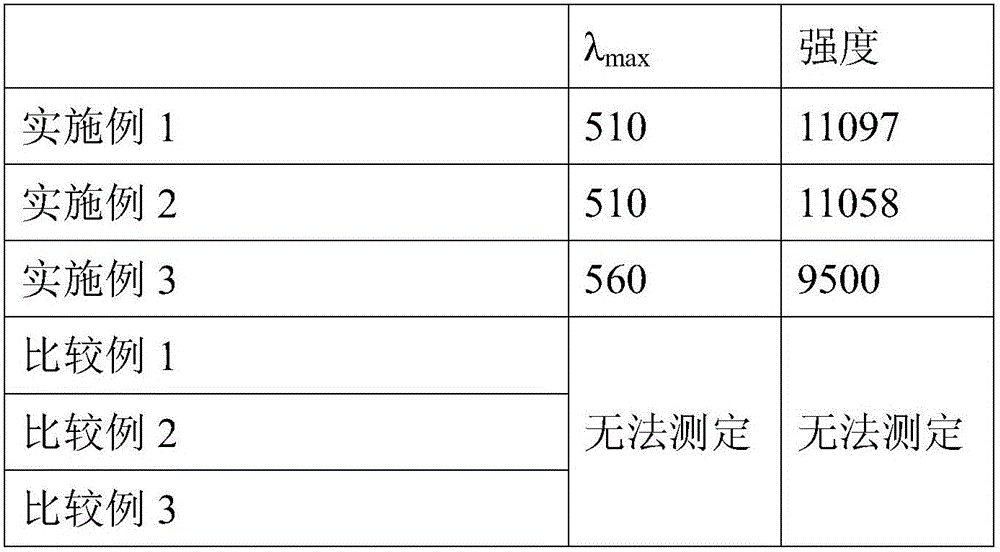

Examples

Synthetic example 1

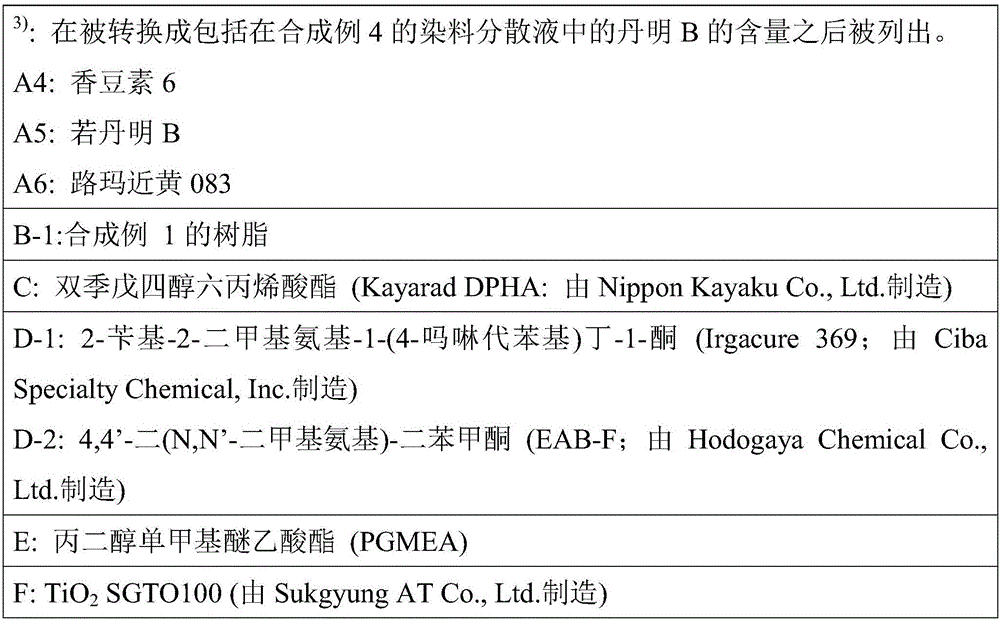

[0185] Synthesis example 1. Synthesis of alkali-soluble resin (B-1)

[0186] A flask with a stirrer, a thermostat, a dropping set and a nitrogen introduction tube was prepared, meanwhile, by introducing, stirring and mixing 74.8 g (0.20 mol) of maleimide, 43.2 g (0.30 mol) of acrylic acid, 118.0 g ( 0.50mol) vinyl toluene, 4g tert-butyl peroxy-2-ethylhexanoate and 40g propylene glycol monomethyl ether acetate (PGMEA) to prepare the monomer drop kit, and by introducing, stirring and mixing 6g n-dodecanediol and 24g PGMEA to prepare the chain transfer agent dropping kit. Then, 395 g of PGMEA was introduced into the flask, and after the atmosphere in the flask was replaced from air to nitrogen, the temperature of the flask was raised to 90° C. while stirring. Subsequently, the monomer and chain transfer agent are started to be added dropwise from the dropping kit. The dropping was carried out for two hours each while keeping the temperature at 90° C., and after one hour, the t...

Synthetic example 2

[0197] Synthesis Example 2. Synthesis of Fluorescent Dye Dispersion (A1) for Color Conversion Layer

[0198] Fluorescent dye (A1): Lumajin Yellow 0830.48 parts by weight

[0199] Extender pigment (A2): 2.88 parts by weight of barium sulfate

[0200] Acrylic dispersant [Disperbyk (registered trademark) 2000: manufactured by BYK-Chemie Japan] 3.84 parts by weight

[0201] Polymer resin B-1 (resin of synthesis example 1) 2.88 parts by weight

[0202] Solvent 1: 55.04 parts by weight of propylene glycol monomethyl ether acetate

[0203] Solvent 2: 5.76 parts by weight of 4-hydroxy-4-methyl-2-pentanone

[0204] 360 parts by weight of zirconia beads with a diameter of 0.2 mm

[0205] The composition was introduced into a salad dressing bottle having a volume of 140 ml, and the resultant was mixed at 60° C. for 10 hours using a paint conditioner to be dispersed. Then, the zirconia beads were removed and the resultant was filtered with a membrane filter having a pore diameter o...

Synthetic example 3

[0206] Synthesis Example 3. Synthesis of Fluorescent Dye Dispersion Liquid (A2) for Color Conversion Layer

[0207] Fluorescent dye dispersion A2 was obtained using the same method as that of fluorescent dye dispersion A1 of Synthesis Example 2, except that coumarin 6 was used as the fluorescent dye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com