A kind of preparation method of environment-friendly rubber filling oil

A rubber-filled oil, environmentally friendly technology, used in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve problems such as poisoning, environmental protection, and no environmental protection treatment of polycyclic aromatic hydrocarbon oil, etc., to improve resource utilization, The effect of superior processing performance and high aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

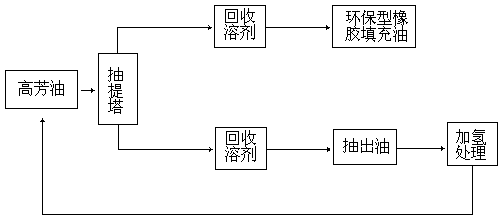

Embodiment 1

[0022] Using high aromatic oil with an aromatic content of 70wt% as a raw material, solvent extraction is carried out, and the product obtained at the top of the extraction tower is recovered from the solvent to obtain an environmentally friendly rubber filler oil, and the product obtained at the bottom of the extraction tower is recovered from the solvent to obtain Extract oil; carry out hydrogenation treatment on the extracted oil to obtain hydrotreated oil, remove a small amount of dissolved hydrogen sulfide, ammonia and other light components in the hydrotreated oil by air stripping, then mix the hydrotreated oil with high aromatic oil and return To the extraction tower for solvent extraction, and so on.

[0023] The solvent for solvent extraction is dimethyl sulfoxide, the extraction stage is 3, the temperature is 90°C, and the mass ratio of solvent to aromatic oil is 3:1.

[0024] The process conditions of hydrotreating are: temperature 350°C, volume fraction ratio of hy...

Embodiment 2

[0027] Using high aromatic oil with an aromatic content of 80wt% as a raw material, solvent extraction is carried out, and the product obtained at the top of the extraction tower is recovered from the solvent to obtain an environmentally friendly rubber filler oil, and the product obtained at the bottom of the extraction tower is recovered from the solvent to obtain Extract oil; carry out hydrogenation treatment on the extracted oil to obtain hydrotreated oil, remove a small amount of dissolved hydrogen sulfide, ammonia and other light components in the hydrotreated oil by air stripping, then mix the hydrotreated oil with high aromatic oil and return To the extraction tower for solvent extraction, and so on.

[0028] The solvent for solvent extraction is N-formylmorpholine, the extraction stage is 3, the temperature is 110°C, and the mass ratio of solvent to aromatic oil is 4:1.

[0029] The process conditions of hydrotreating are: temperature 300°C, volume fraction ratio of h...

Embodiment 3

[0032] Using high aromatic oil with an aromatic content of 90wt% as a raw material, solvent extraction is carried out, and the product obtained at the top of the extraction tower is recovered from the solvent to obtain an environmentally friendly rubber filler oil, and the product obtained at the bottom of the extraction tower is recovered from the solvent to obtain Extract oil; carry out hydrogenation treatment on the extracted oil to obtain hydrotreated oil, remove a small amount of dissolved hydrogen sulfide, ammonia and other light components in the hydrotreated oil by air stripping, then mix the hydrotreated oil with high aromatic oil and return To the extraction tower for solvent extraction, and so on.

[0033] The solvent for solvent extraction is furfural, the extraction stage is 3, the temperature is 80°C, and the mass ratio of solvent to aromatic oil is 1.5:1.

[0034] The process conditions of hydrotreating are: temperature 370°C, volume fraction ratio of hydrogen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com