Slowly digestible starch and preparation method thereof

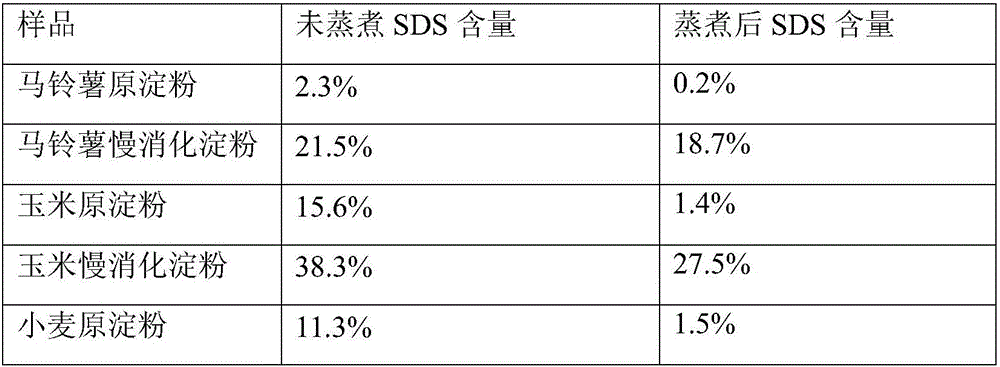

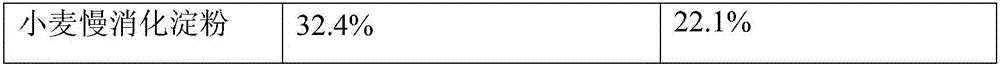

A slow-digesting starch and homogeneous emulsification technology, applied in food ingredients as emulsifiers, food science, applications, etc., can solve the problems of decreased SDS content and increased digestibility, and achieve low SDS content, delayed digestion, and low impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention adopts the physical embedding method to prepare a kind of slowly digestible starch, and its structure is a monodisperse core-shell capsule structure, the "core" is starch granules, and the "shell" is compounded by sodium alginate, gellan gum and chitosan . Concrete preparation method comprises the following steps:

[0026] Prepare sodium alginate aqueous solution, gellan gum aqueous solution and chitosan glacial acetic acid solution respectively. Take a certain amount of sodium alginate and dissolve it in pure water to prepare a 0.2-0.8% g / mL sodium alginate aqueous solution, preferably a 0.4-0.6% g / mL sodium alginate aqueous solution; take a certain amount of gellan gum and dissolve it In hot water at ≥80°C, configure 0.01-0.05% g / mL gellan gum aqueous solution, preferably 0.02-0.04% g / mL gellan gum aqueous solution; take a certain amount of chitosan and dissolve it in 0.5-1 % (v / v) glacial acetic acid solution, be configured as 0.05~0.2% g / mL c...

Embodiment 1

[0037](1) Weigh 5.0g of sodium alginate and dissolve it in 1000ml of pure water, place it on a magnetic stirrer at room temperature and stir for 12h, and configure it into a 0.5% (w / v) sodium alginate solution; weigh 0.3g of gellan gum Dissolve in 1000ml of pure water at 80°C, place on a magnetic stirrer at room temperature and stir for 12h, and configure a 0.03% (w / v) gellan gum solution; weigh 1.0g of chitosan and dissolve it in 1000ml of glacial acetic acid ( 1%, v / v) solution, configured as 0.1% (w / v) chitosan solution.

[0038] (2) Sodium alginate solution, gellan gum solution, and chitosan solution were mixed at a volume ratio of 5:1:1 for 24 hours in a magnetically stirred water bath at 50°C and at a speed of 800 rpm to form sodium alginate / gellan gum / chitosan mixed solution.

[0039] (3) Configure 100ml of 10% (w / v) potato starch slurry, and slowly add 50ml of sodium alginate / gellan gum / chitosan mixed solution to the starch slurry at 50°C and 800 rpm in a magnetic...

Embodiment 2

[0046] (1) Weigh 2.0g of sodium alginate and dissolve it in 1000ml of pure water, place it on a magnetic stirrer at room temperature and stir for 12h, and configure it into a 0.2% (w / v) sodium alginate solution; weigh 0.1g of gellan gum Dissolve in 1000ml of pure water at 85°C, place on a magnetic stirrer at room temperature and stir for 12h, and configure a 0.01% (w / v) gellan gum solution; weigh 0.5g chitosan and dissolve in 1000ml of glacial acetic acid ( 0.7%, v / v) solution, is configured as 0.05% (w / v) chitosan solution.

[0047] (2) Sodium alginate solution, gellan gum solution, and chitosan solution were mixed for 12 hours at a volume ratio of 3:2:1 in a magnetically stirred water bath at 60°C and at a speed of 500 rpm to form sodium alginate / gellan gum / chitosan mixed solution.

[0048] (3) Prepare 100ml of 15% (w / v) corn starch slurry, and slowly add 50ml of sodium alginate / gellan gum / chitosan mixed solution to the starch slurry at 40°C and 500 rpm in a magneticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com