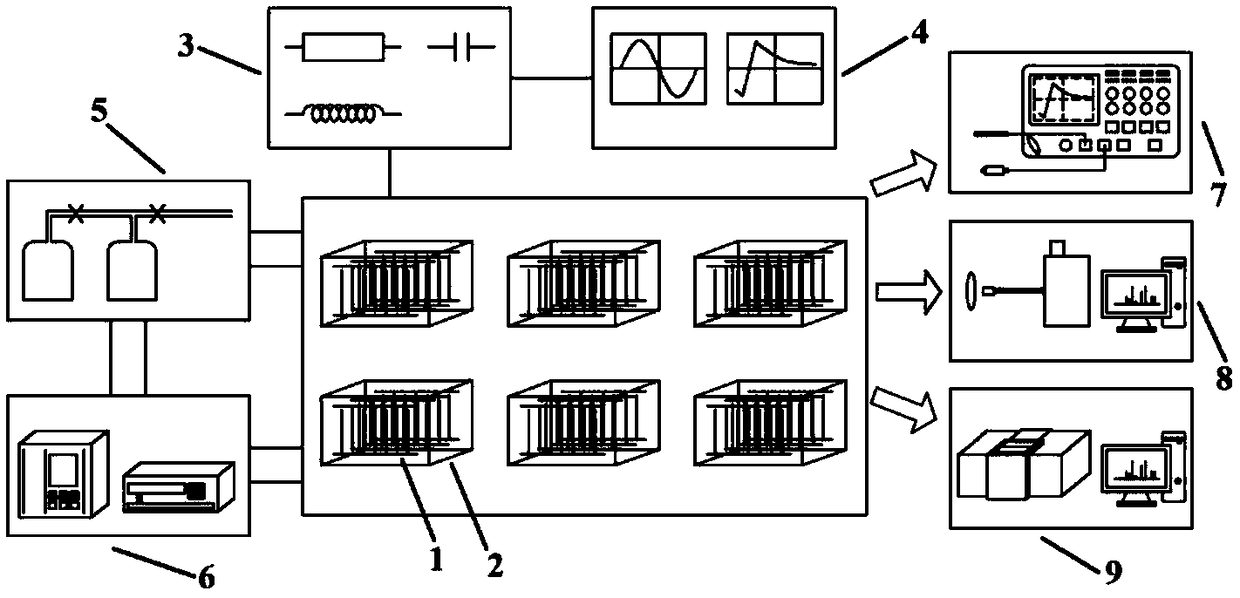

[0004] In order to solve the traditional catalytic removal of NO x The method has problems such as high cost of raw materials, complex device structure, and easy failure of the catalyst, and the

surface discharge of the "sandwich" structure is difficult to be applied on a spatial scale, and there are difficulties in realizing and diagnosing large-area discharge. The present invention provides a large-area

surface discharge. Synergistic Catalyst Removal of NO x The modular device and experimental method are mainly composed of arrayed wire-wire electrodes,

reaction chamber, matching system, power supply system,

gas supply system, gas detection system, electrical

diagnostic system, optical

diagnostic system, and catalyst characterization system; the array type The line-line

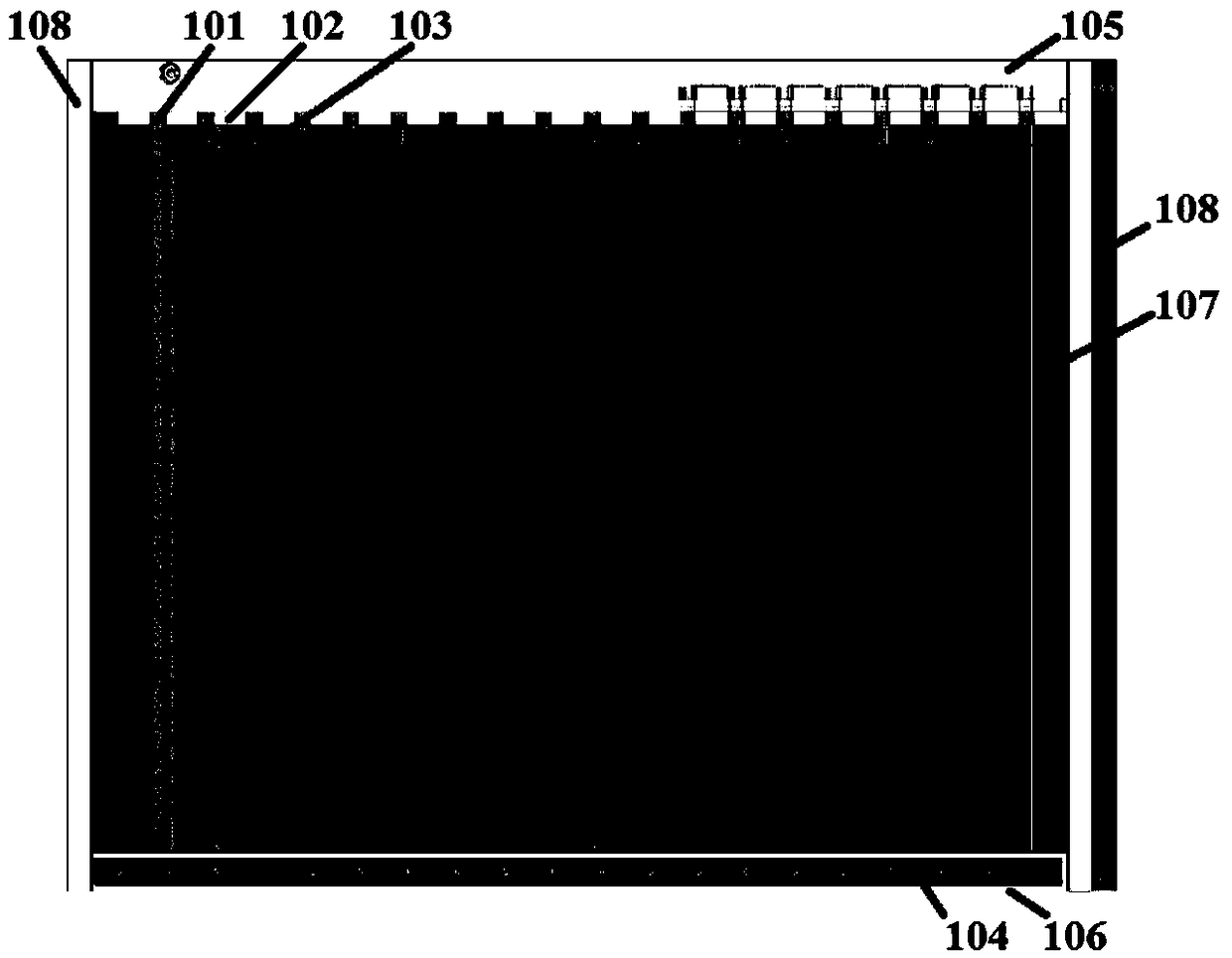

electrode is mainly composed of a plurality of linear high-

voltage electrodes,

dielectric tubes, linear ground electrodes, and fixtures arranged in an array; among them, the

dielectric tube and the linear ground

electrode are tubular structures, and the linear high-

voltage electrodes contain

solid metal Stud; the inner

diameter of the

dielectric tube is consistent with the outer

diameter of the linear ground

electrode; the linear ground electrode is inserted into the

dielectric tube, the

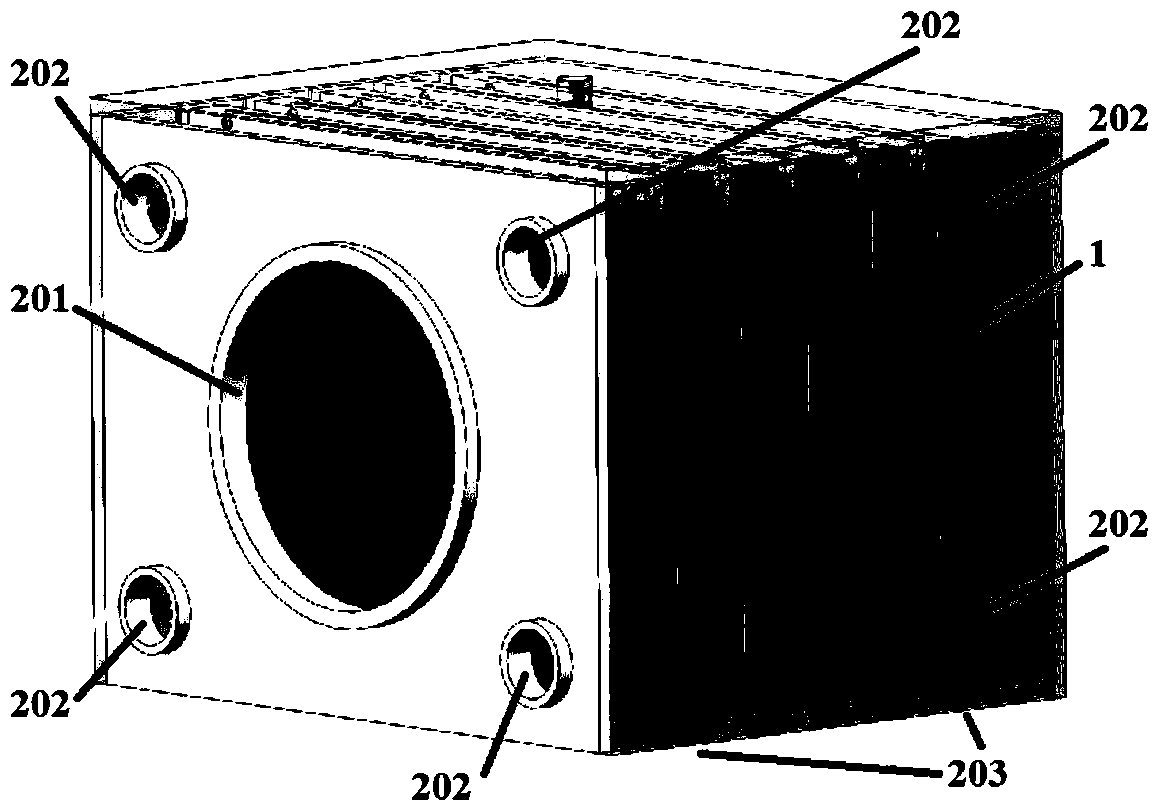

dielectric tube is arranged in an array, and the linear high-voltage electrode is inserted into the gap between the dielectric tubes; it is made of insulating plates The upper fixing part and the lower fixing part are respectively fixed on the top surface and the bottom surface of the sealed

reaction chamber made of insulating material; the upper fixing part and the lower fixing part have holes, and the length of the linear high-voltage electrode is longer than that of the upper fixing part and the lower fixing part. The distance between the fixtures; the top of the linear high-voltage electrode and the medium

pipe pass through the hole of the upper fixture and are fixed on the upper fixture; the lower ends of the linear high-voltage electrode and the linear ground electrode pass through the hole of the lower fixture, and fixed on the lower fixture; the top of each linear high-voltage electrode is connected to the

metal plate between the upper fixture and the reaction chamber to form an array high-voltage electrode; the array high-voltage electrode is connected to the power system through a matching system; the ground electrode The terminal board is fixed between the lower fixture and the reaction chamber, and each linear ground electrode is connected to the ground electrode terminal board, and grounded through the ground electrode terminal board; The gas uniform plate is parallel to the front and rear sides of the reaction chamber, and fixed on both sides of the electrode in the arrayed line-line electrode through the corresponding hole groove of the lower fixing member, and the catalyst is placed in the gap formed between the gas uniform plate and the electrode; the reaction chamber There are a number of transparent air holes for gas passage symmetrically opened on the front and rear sides; the

gas supply system is divided into two gas paths, the A path leads to the gas detection system, and the B path passes through the gas holes through the reaction chamber and then into the gas detection system. On-line detection of reaction

gas concentration; large-area

dielectric barrier discharge along the surface of the dielectric tube occurs between the linear high-voltage electrode and the linear ground electrode to form a discharge area; there is a

quartz observation window on the side of the reaction chamber, and the electrical diagnosis system and belt The

optical diagnosis system of the wired

fiber optic probe conducts online diagnosis of the discharge plasma through the

quartz observation window; before the

optical diagnosis, part of the photosensitive element of the linear

fiber optic probe is blocked, and the spectrum is observed at the same time to determine the corresponding relationship between the photosensitive element and the

spatially resolved spectrum; Adjust the matching system to make the voltage and current waveforms stable, and the spectral intensity reach the maximum value to ensure the

power output of the power system; the catalyst characterization system characterizes the catalyst in the discharge-removal reaction

Login to View More

Login to View More  Login to View More

Login to View More