MgO-added 0.45BCTZS-0.55BNT high-energy-storage-density ceramic material and preparation method therefor

A technology of 0.45BCTZS-0.55BNT, 0.45bctzs-0.55bnt-xwt%mgo, applied in the field of electronic ceramics, can solve problems such as difficult to meet the requirements of practical applications, achieve uniform microscopic morphology, improve breakdown strength, increase Effect of grain boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

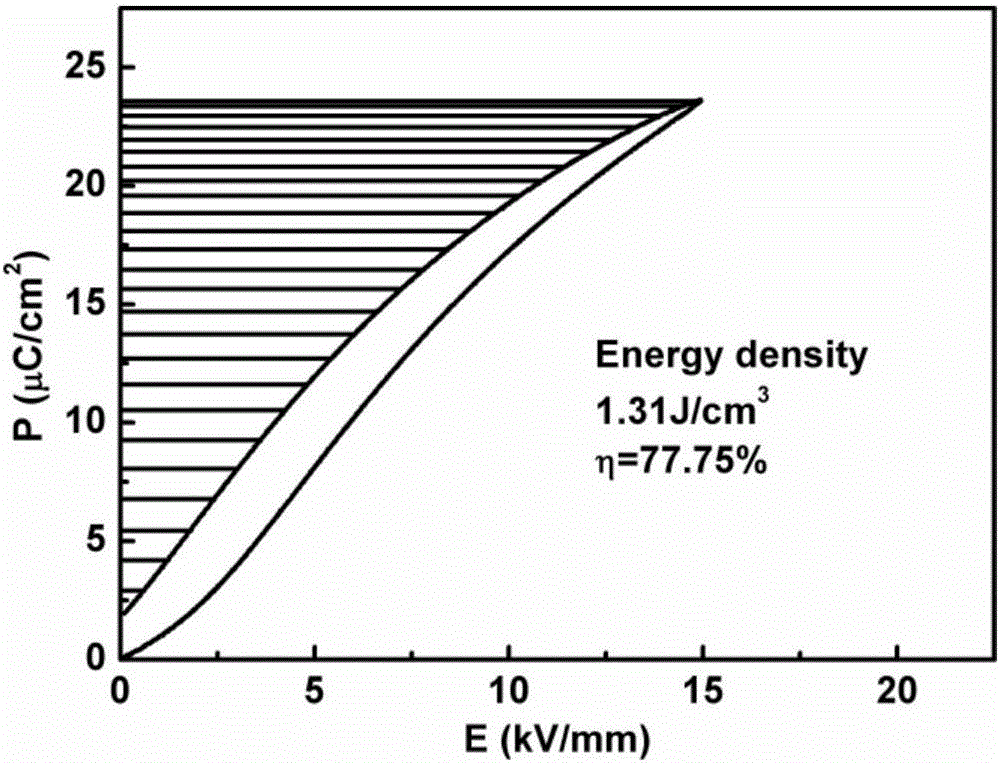

Embodiment 1

[0029] The preparation method of the 0.45BCTZS-0.55BNT high energy storage density ceramic material that adds MgO, according to chemical formula Ba 0.85 Ca 0.15 Ti 0.85 Zr 0.1 sn 0.05 o 3 (BCTZS), mix barium carbonate, calcium carbonate, titanium dioxide, tin dioxide and zirconia evenly, and then keep warm at 1260°C for 2 hours to synthesize BCTZS ceramic powder, according to the chemical formula Bi 0.5 Na 0.5 TiO 3 (BNT), sodium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and then kept at 840°C for 4h to synthesize BNT ceramic powder. Mix BCTZS ceramic powder, BNT ceramic powder and MgO according to the chemical formula 0.45BCTZS-0.55BNT-3wt%MgO, use deionized water as the ball milling medium and ball mill for 6 hours to mix evenly, then dry at 80°C, granulate and shape Finally, it is sintered into porcelain at 1180°C for 2 hours.

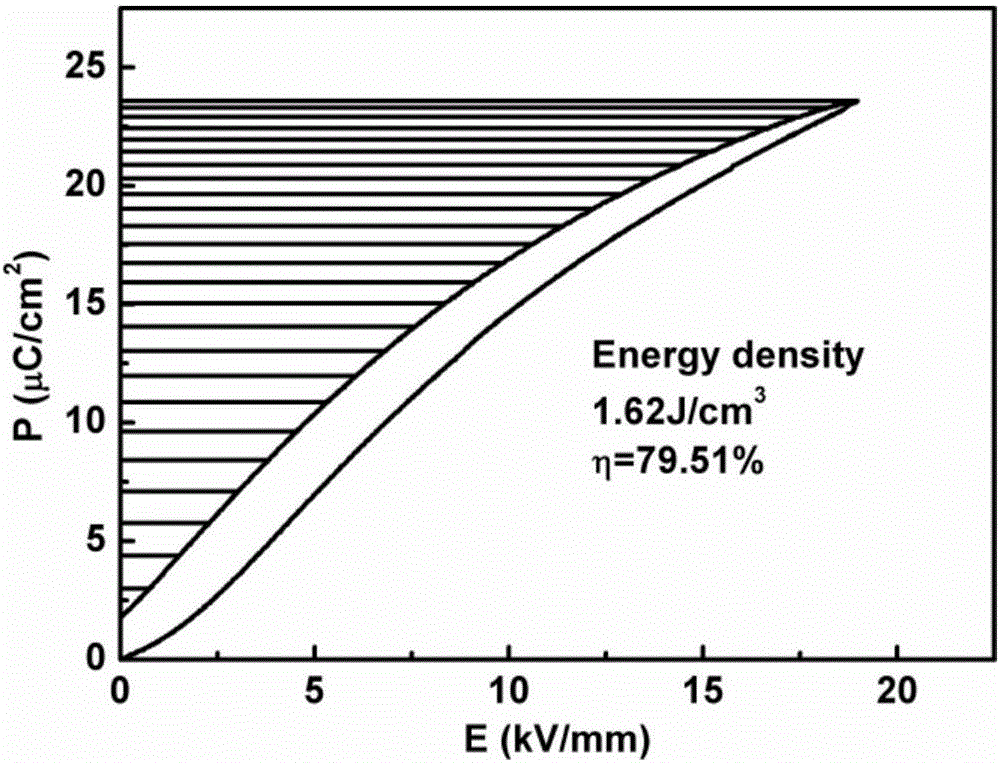

Embodiment 2

[0031] The preparation method of the 0.45BCTZS-0.55BNT high energy storage density ceramic material that adds MgO, according to chemical formula Ba 0.85 Ca 0.15 Ti 0.85 Zr 0.1 sn 0.05 o 3 (BCTZS), mix barium carbonate, calcium carbonate, titanium dioxide, tin dioxide and zirconia evenly and then keep warm at 1250°C for 3h to synthesize BCTZS ceramic powder, according to the chemical formula Bi 0.5 Na 0.5 TiO 3 (BNT), sodium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and then kept at 850°C for 5h to synthesize BNT ceramic powder. Mix BCTZS ceramic powder, BNT ceramic powder and MgO according to the chemical formula 0.45BCTZS-0.55BNT-3.5wt% MgO, use deionized water as the ball milling medium and ball mill for 7 hours to mix evenly, then dry at 85°C, granulate, After molding, it is sintered into porcelain at 1150°C for 4 hours.

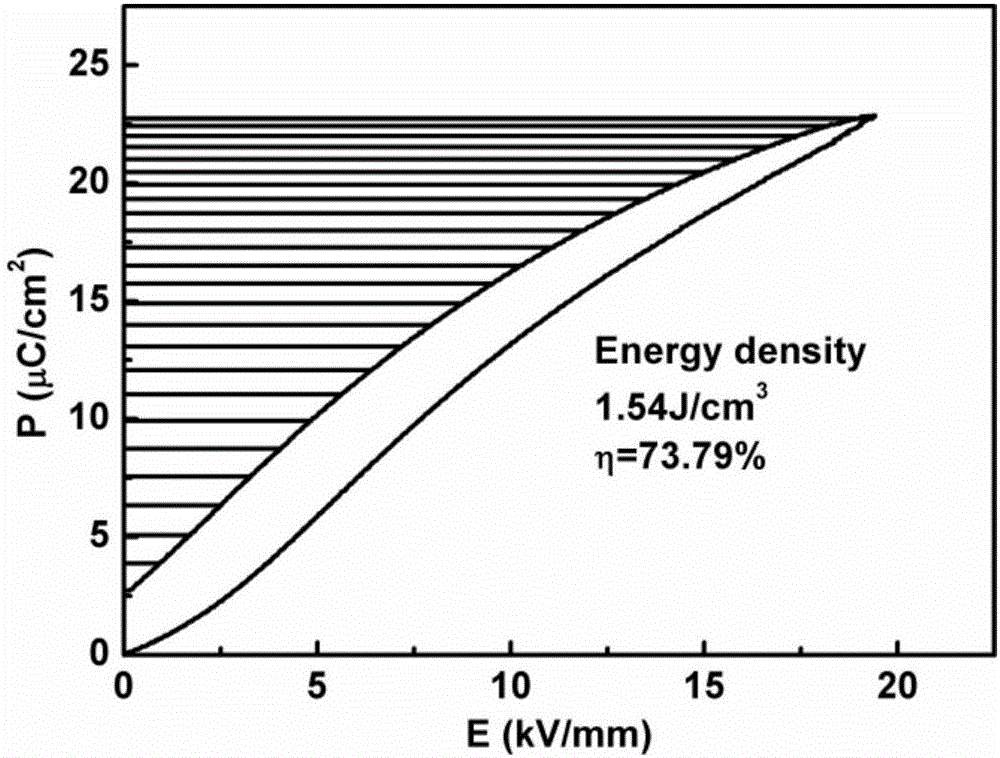

Embodiment 3

[0033] The preparation method of the 0.45BCTZS-0.55BNT high energy storage density ceramic material that adds MgO, according to chemical formula Ba 0.85 Ca 0.15 Ti 0.85 Zr 0.1 sn 0.05 o 3 (BCTZS), mix barium carbonate, calcium carbonate, titanium dioxide, tin dioxide and zirconia evenly and then keep warm at 1270°C for 4h to synthesize BCTZS ceramic powder, according to the chemical formula Bi 0.5 Na 0.5 TiO 3 (BNT), sodium carbonate, bismuth oxide and titanium dioxide were mixed uniformly and then kept at 830°C for 5.5h to synthesize BNT ceramic powder. Mix BCTZS ceramic powder, BNT ceramic powder and MgO according to the chemical formula 0.45BCTZS-0.55BNT-4wt%MgO, use deionized water as the ball milling medium and ball mill for 8 hours to mix evenly, then dry at 90°C, granulate and shape Finally, it is sintered into porcelain at 1160°C for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com