Method for extracting small-molecular oyster polypeptides

A technology of oyster polypeptide and extraction method, which is applied in the field of extraction of small molecule oyster polypeptide, to achieve the effects of alleviating oversupply, ensuring biological activity, broad market space and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

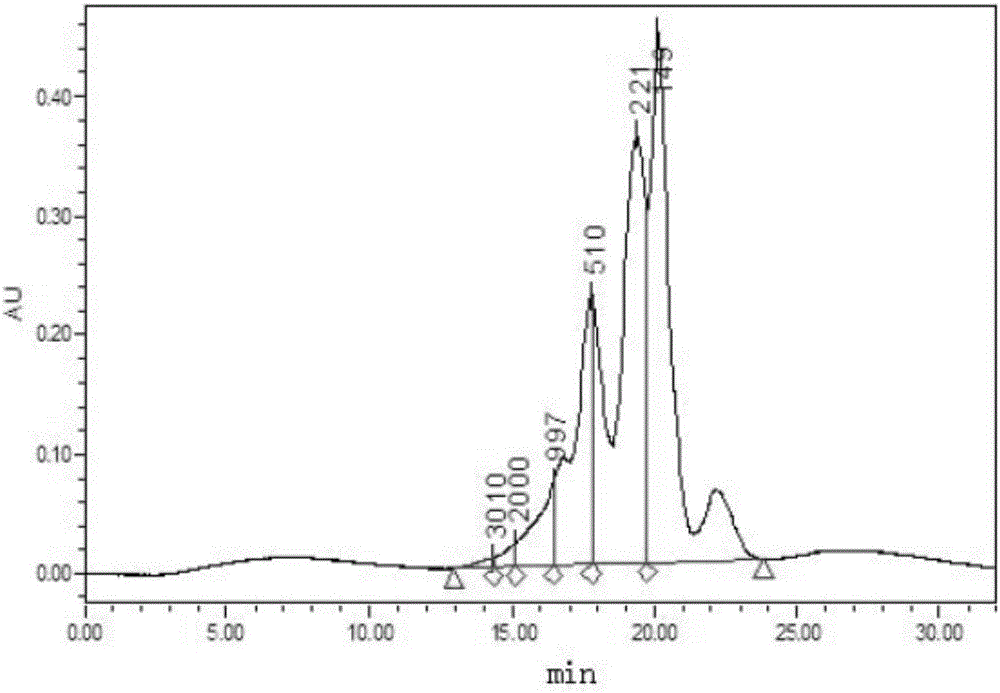

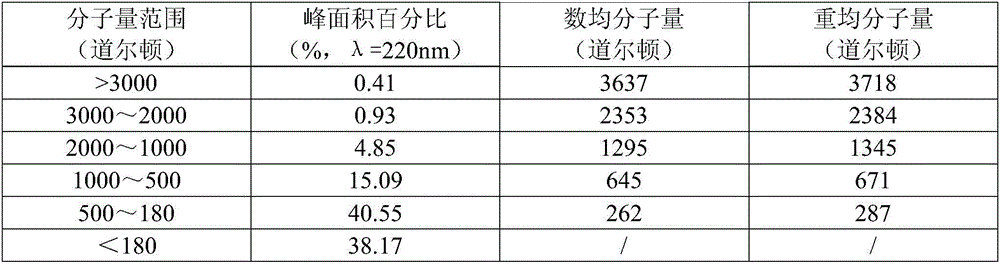

Image

Examples

Embodiment 1

[0016] The method for extracting small molecule oyster polypeptides in Example 1 includes the following steps:

[0017] (1) Using fresh oyster meat that has been desilted and washed as raw material, put the raw material and water into the biological enzymatic hydrolysis tank at a volume ratio of 1:3, and add compound enzymes and activated carbon to the biological enzymatic hydrolysis tank. The compound enzyme performs compound enzymatic hydrolysis treatment on the raw materials, in which the addition amount of activated carbon is 3% of the weight of oyster meat, the addition amount of compound enzyme is 0.5% of the weight of oyster meat, and the compound enzyme is composed of collagenase and alkaline protease at a ratio of 1:1 The compound enzymatic hydrolysis treatment conditions are as follows: the reaction temperature is 55°C, the pH value is 6.5, the reaction time is 12 hours, and the enzymatic hydrolysis product is obtained after the compound enzymatic hydrolysis treatment;

...

Embodiment 2

[0019] The method for extracting small molecule oyster polypeptides in Example 2 includes the following steps:

[0020] (1) Using fresh oyster meat that has been desilted and washed as raw material, put the raw material and water into a biological enzymatic hydrolysis tank at a volume ratio of 1:6, and add compound enzymes and activated carbon to the biological enzymatic hydrolysis tank. The compound enzyme performs compound enzymatic hydrolysis treatment on the raw materials. Among them, the amount of activated carbon added is 2% of the weight of oyster meat, the amount of compound enzyme added is 1.9% of the weight of oyster meat, and the compound enzyme is composed of collagenase and alkaline protease at a ratio of 2:3 The compound enzymatic hydrolysis treatment conditions are as follows: the reaction temperature is 50°C, the pH value is 7.0, the reaction time is 7 hours, and the enzymatic hydrolysis product is obtained after the compound enzymatic hydrolysis treatment;

[0021]...

Embodiment 3

[0022] The method for extracting small molecule oyster polypeptides in Example 3 includes the following steps:

[0023] (1) Using fresh oyster meat that has been desilted and washed as raw material, put the raw material and water into the biological enzymatic hydrolysis tank at a volume ratio of 1:2, and add compound enzymes and activated carbon to the biological enzymatic hydrolysis tank. The compound enzyme performs compound enzymatic hydrolysis treatment on the raw materials. The addition amount of activated carbon is 5% of the weight of oyster meat, the addition amount of compound enzyme is 0.3% of the weight of oyster meat, and the compound enzyme is composed of collagenase and alkaline protease at a ratio of 2:1 The compound enzymolysis treatment conditions are as follows: the reaction temperature is 60°C, the pH value is 6.0, the reaction time is 16 hours, and the enzymolysis product is obtained after the compound enzymolysis treatment;

[0024] (2) Pour the enzymatic hydrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com