Ganoderma lucidum producing method

A technology of Ganoderma lucidum and Ganoderma lucidum triterpenes, applied in the fields of botanical equipment and methods, mushroom cultivation, gardening, etc., can solve the problems of consumers' lack of confidence in the purchase of Ganoderma lucidum products and low transparency of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for producing ganoderma lucidum. Include the following steps:

[0019] (1) Bacteria bag culture: transfer the original species to a 37×22 polyethylene plastic bag on a clean bench, and cultivate at 25°C for 35 days until the mycelia are covered with the fungus bag; the formula of the fungus bag is: tea stalk 20 61 parts of sawdust, 15 parts of bran, 3 parts of corn flour, 1 part of gypsum, pH 4, water content 60%, sterilized at 121°C for 180min.

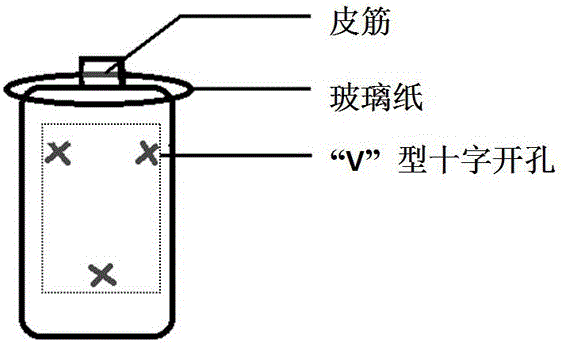

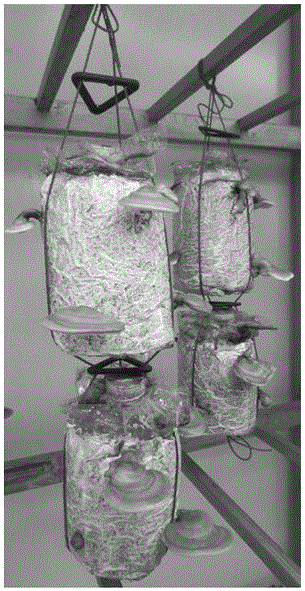

[0020] (2) Open the bag and produce mushrooms: tie a layer of circular cellophane with a diameter of 10cm on the mushroom cap with a rubber band, 2.5cm away from the two ends of the mushroom bag, and open 6 cross holes with a diameter of 1.5cm around in a "V" shape equidistant , use the rope to hang the mushroom bag to produce mushrooms, the temperature is 26°C, and the air humidity is 85%.

[0021] (3) Harvesting: Harvest when the ganoderma is not fully mature, that is, when the white or yellow growth ring on the e...

Embodiment 2

[0026] A method for fruiting ganoderma lucidum. Include the following steps:

[0027] (1) Bacteria bag culture: transfer the original seed to a 37×22 polyethylene plastic bag on a clean bench, and cultivate at 28°C for 30 days until the mycelium is covered with the bag; the formula of the bag is: tea stem 20 61 parts of sawdust, 15 parts of bran, 3 parts of corn flour, 1 part of gypsum, pH 6, water content 65%, sterilized at 121°C for 180min.

[0028] (2) Open the bag and produce mushrooms: tie a layer of circular cellophane with a diameter of 12cm on the mushroom cap with a rubber band, 4.0cm away from both ends of the mushroom bag, and open 8 cross holes with a diameter of 2.5cm in a "V" shape equidistant around it , Hang the fungus bag with a rope to produce mushrooms, the temperature is 28°C, and the air humidity is 90%.

[0029] (3) Harvesting: Harvest when the ganoderma is not fully mature, that is, when the white or yellow growth ring on the edge of the ganoderma cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com