Compound essential oil as well as preparation method and application thereof

A compound essential oil and extraction technology, applied in application, essential oil/fragrance, food preservation, etc., can solve the problems of complex and diverse ingredients, low utilization rate, high production cost, etc., and achieve simple raw material ratio, high active ingredients, non-toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

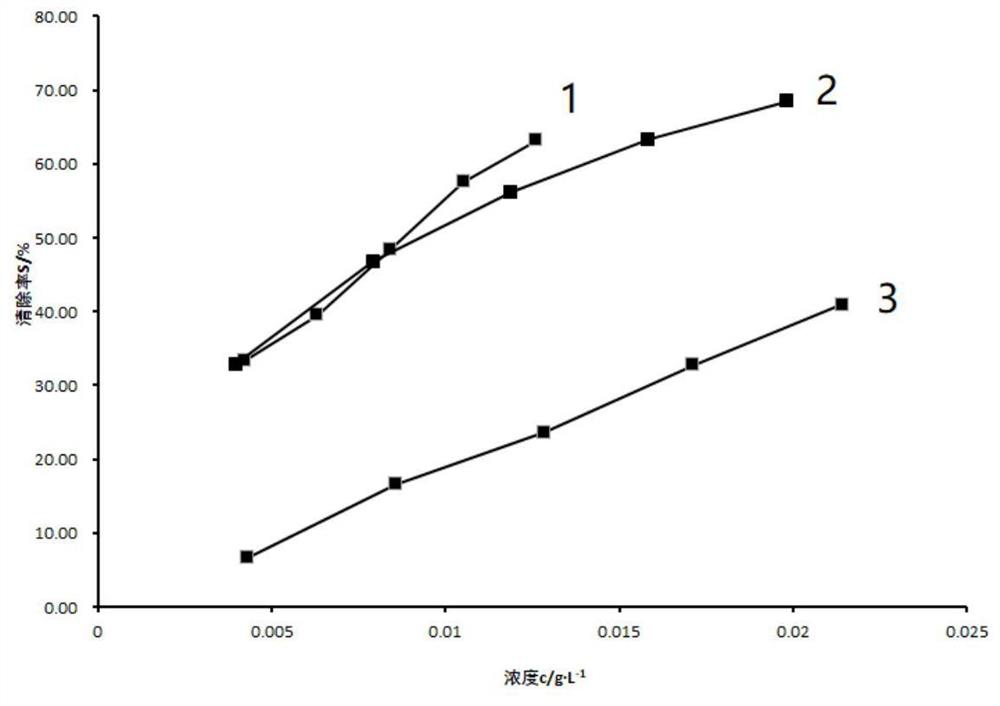

[0046] Get pulverized into 40 order cloves and rosemary, take mixed sample 20g respectively (raw material cloves and rosemary mass ratio M=1:0; 9:1; 7:1; 5:1; 3:1; 1: 1; 1:3; 1:5; 1:7; 1:9; 0:1) into a 100mL supercritical extraction kettle. At an extraction temperature of 30°C and an extraction pressure of 30 MPa, one part of clove essential oil, one part of rosemary essential oil and 9 parts of compound essential oil were extracted.

[0047] The following clove essential oil, rosemary essential oil and compound essential oil prepared in Example 1 are tested for activity

[0048] 1. Detection method

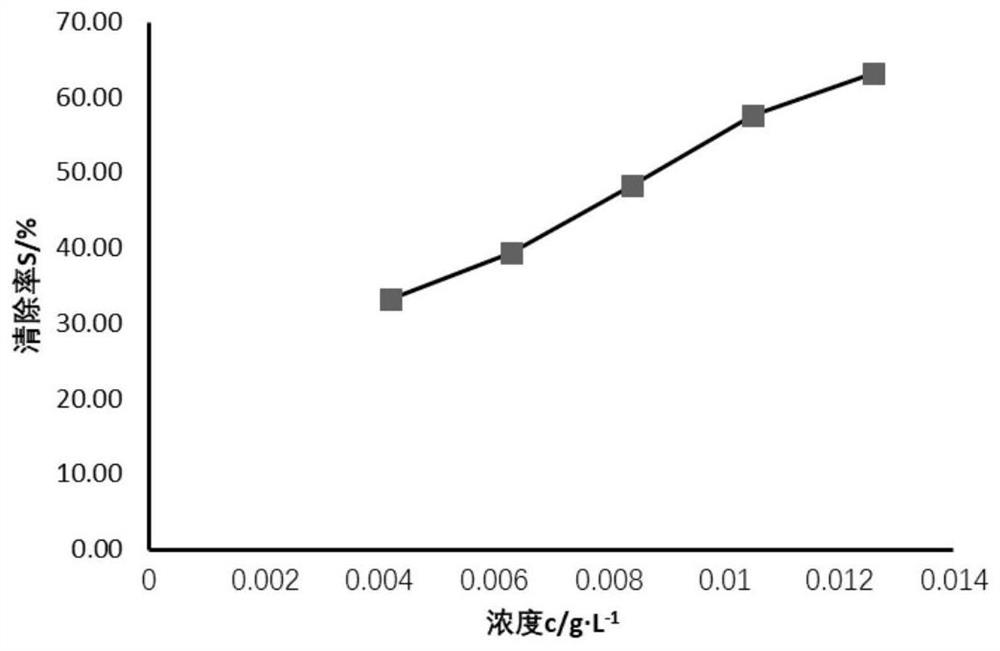

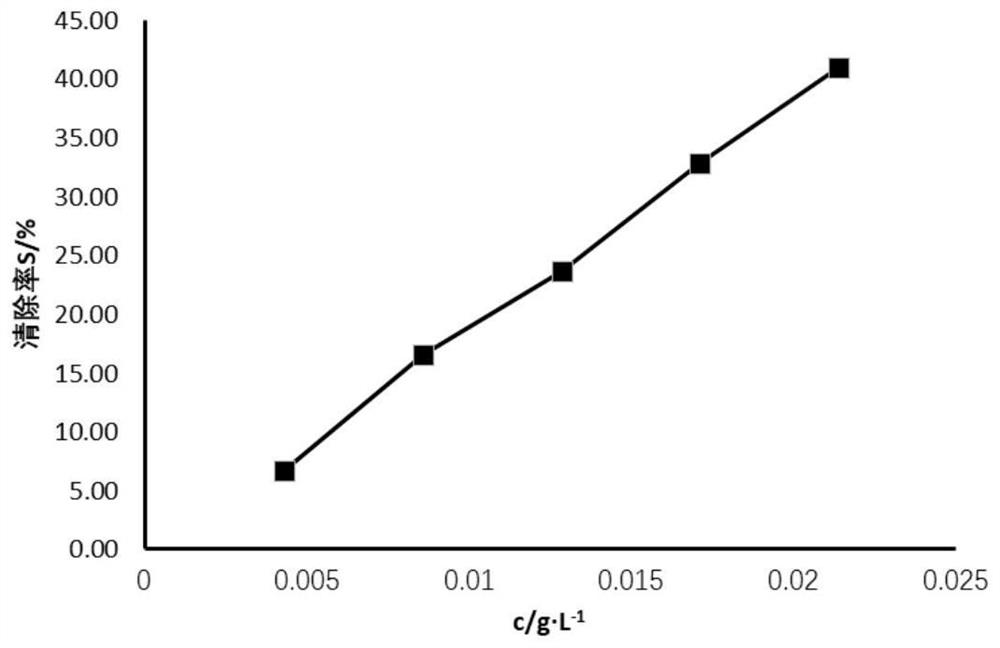

[0049] 1.1. Determination of antioxidant activity by DPPH method

[0050]Weigh about 0.0100g of essential oil, dissolve and dilute 500 times with absolute ethanol to obtain an essential oil sample with a concentration of 0.042mg / mL. Take a total of 11 10mL volumetric flasks. Divided into blank (1), control group (5) and experimental group (5) a total of 3 groups. Take 1mL, 2...

Embodiment 2

[0094] The influence of different conditions on oil yield when embodiment 2 prepares compound essential oil

[0095] The crushed cloves and rosemary are mixed according to the mass ratio of 1:3 to obtain compound powder, and then the essential oil is extracted according to the following conditions, and the extracted essential oil is bottled, sealed, refrigerated, and set aside. Calculate the oil yield according to formula (2). (The fluctuation of gas flow rate is relatively large, and the present embodiment uses CO 2 The flow rate is controlled at about 2.5L / min)

[0096] Oil yield = quality of essential oil / quality of compound raw materials × 100% (2)

[0097] 1. Single factor analysis

[0098] 1) Effect of extraction time on oil yield

[0099] Take 5 parts of compound powder, each 10g, under the conditions of temperature 40°C, pressure 30Mpa, degree of pulverization 60 mesh, with supercritical CO 2 The instrument carries out the extraction and calculates the oil yield...

Embodiment 3

[0114] Example 3 Application of compound essential oil (mass ratio of clove and rosemary raw materials is 1:1) to red grape preservation

[0115] Mix the compound essential oil (mass ratio of clove and rosemary raw materials: 1:1): acetone = 1:10, fill it up with sterile water, and prepare the concentrations of 1mL / L, 3mL / L, 5mL / L, and Acetone and sterile water were used as controls. The red grapes were soaked in different concentrations of treatment solutions for 1.5 min, then taken out and air-dried naturally. Pack it in a plastic wrap bag and store it in a 15°C incubator.

[0116] 1. Preparation and activity determination of polyphenol oxidase activity (PPO) enzyme solution

[0117] 1) Preparation of enzyme solution: Take 10 g of pulp, add 0.5 g of PVP to 20 mL of 0.2 mol / L phosphate buffer (pH=6.4), grind in an ice bath, centrifuge at 12,000 rpm at 4°C for 20 min, and take the supernatant to measure the enzyme activity.

[0118] 2) Determination of enzyme activity: Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com