Efficient composite inorganic antibacterial agent and preparation method thereof

An inorganic antibacterial agent and high-efficiency technology, applied in the field of nanomaterial preparation, can solve the problems of inability to exert the synergistic effect of the carrier and various antibacterial ingredients, difficulty in dispersing the carrier and antibacterial ingredients, single antibacterial active ingredient, etc., to achieve efficient inhibition of bacterial reproduction, Good market prospect, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

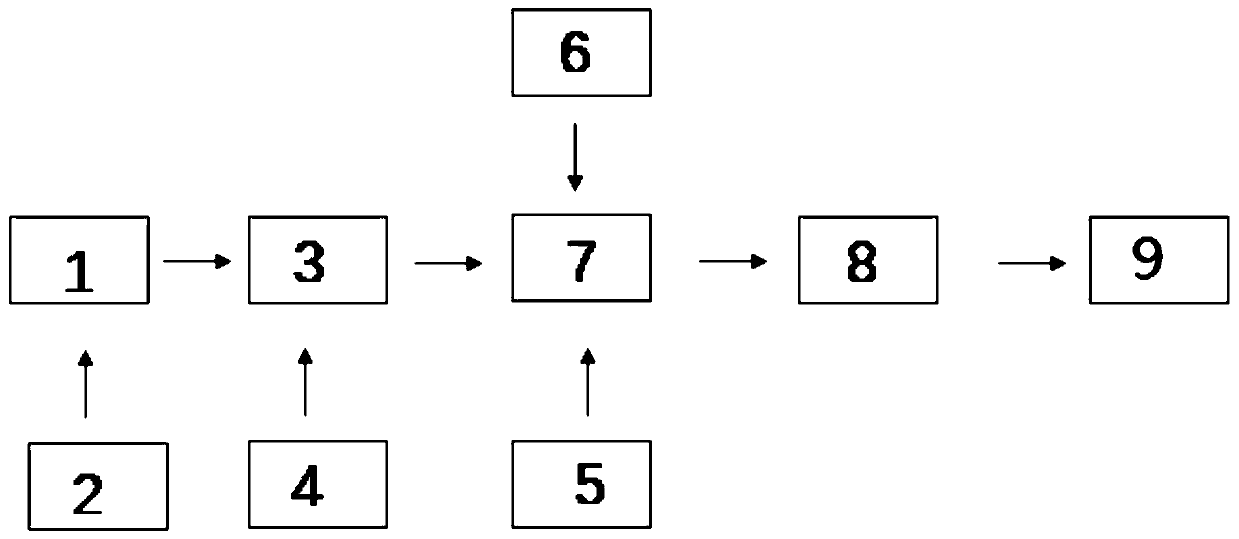

Method used

Image

Examples

Embodiment 1

[0045] Mix 100 g of needle-shaped palygorskite powder with a purity of 95% and 1 g of polyquaternium, add 500 g of deionized water, mix well, then add 2500 g of deionized water, and process it with an ultrasonic processor for 2 hours. In addition, 100 g of deionized water was added to 3 g of graphene oxide, ultrasonically treated for 2 hours, and the resulting suspension was slowly added to the aforementioned palygorskite modified aqueous suspension, stirred while ultrasonically treated for 1 hour, and then added 40g anatase nano-TiO 2 , 3g of silver nitrate, mixed evenly, filtered excess deionized water, and modulated into a slurry with a water content of 60%. The prepared slurry was ground at a high speed of 300 rpm for 12 hours with a high-energy planetary ball mill. Dry the ground powder slurry at 100°C to remove the moisture in the slurry. Calcined at 600°C for 4 hours to make nano-TiO 2 and Ag ions supported on palygorskite. Grind on a high-energy planetary ball mill...

Embodiment 2

[0047] Mix 100 g of velvety palygorskite powder with a purity of 96% and 1 g of polyquaternium, add 500 g of deionized water, mix well, then add 2000 g of deionized water, and treat with an ultrasonic processor for 2.5 hours. In addition, 100 g of deionized water was added to 3 g of graphene oxide, ultrasonically treated for 2.5 hours, and the resulting suspension was slowly added to the aforementioned palygorskite modified aqueous suspension, stirred while ultrasonically treated for 1 hour, and then added 37g anatase nano-TiO 2 1. 4g metal oxide ZnO, mix evenly, filter excess deionized water, and prepare a slurry with a water content of 50%. The prepared slurry was ground at a high speed of 350 rpm for 12 hours with a high-energy planetary ball mill. Dry the ground powder slurry at 150°C to remove the moisture in the slurry. Calcined at 600°C for 4 hours to make nano-TiO 2 and ZnO supported on palygorskite. Grind on a high-energy planetary ball mill to a particle size of ...

Embodiment 3

[0049] Mix 100 g of fibrous palygorskite powder with a purity of 96% and 1 g of polyquaternium, add 500 g of deionized water, mix well, then add 3000 g of deionized water, and process with an ultrasonic processor for 3 hours. In addition, 100 g of deionized water was added to 3 g of graphene oxide, ultrasonically treated for 2.5 hours, and the resulting suspension was slowly added to the aforementioned palygorskite modified aqueous suspension, stirred while ultrasonically treated for 1 hour, and then added 35g anatase nano-TiO 2 , 6g of silver nitrate, mixed evenly, filtered excess deionized water, and modulated into a slurry with a water content of 70%. The prepared slurry was ground at a high speed of 400 rpm for 15 hours with a high-energy planetary ball mill. Dry the ground powder slurry at 120°C to remove the moisture in the slurry. Calcined at 500°C for 4 hours to make nano-TiO 2 and Ag ions supported on palygorskite. Grind on a high-energy planetary ball mill to a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com