A method for connection between magnesium alloy and silk fibroin

A technology of silk fibroin and magnesium alloy, which can be used in pharmaceutical formulations, prostheses, drug delivery, etc., can solve problems such as unstable physical connections, and achieve the effect of stable combination and ease of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

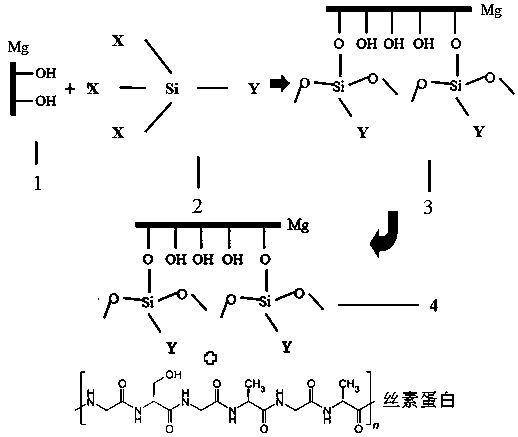

Method used

Image

Examples

Embodiment 1

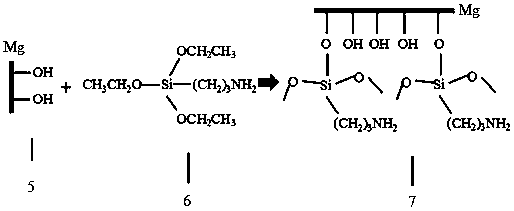

[0034] This embodiment provides a low-temperature connection method between magnesium alloy and silk fibroin by using APTES, and the specific implementation steps are as follows:

[0035] (1) Polishing: A magnesium alloy with a diameter of 10 mm and a thickness of 2 mm was mechanically polished.

[0036] (2) Cleaning: Put the polished magnesium alloy into an acetone solution with a volume concentration of 70% and perform ultrasonic cleaning at a temperature of 25°C; then rinse with ethanol and deionized aqueous solution for 3 min respectively.

[0037] (3) Initial modification of magnesium alloy surface: ① Take a certain volume of APTES solution and pour it into a certain volume of toluene solution to prepare an APTES toluene solution with a volume concentration of 2%; ② Put the above magnesium alloy into the prepared APTES toluene Soak in the solution for 10 h, the soaking temperature is room temperature, and use silane coupling agent to modify the surface of magnesium alloy....

Embodiment 2

[0047] This embodiment provides a low-temperature connection method between magnesium alloy and silk fibroin by using methyltriethoxysilane, and the specific implementation steps are as follows:

[0048] (1) Polishing: A magnesium alloy with a diameter of 10 mm and a thickness of 2 mm was mechanically polished.

[0049] (2) Cleaning: Put the polished magnesium alloy into an acetone solution with a volume concentration of 70% and perform ultrasonic cleaning at a temperature of 25°C; then rinse with ethanol and deionized aqueous solution for 3 min respectively.

[0050] (2) Initial modification of magnesium alloy surface: ① Take a certain volume of methyltriethoxysilane solution and pour it into a certain volume of toluene solution to prepare a methyltriethoxysilane toluene solution with a volume concentration of 2%; ② Soak the above-mentioned magnesium alloy in the prepared methyltriethoxysilane toluene solution for 10 h at room temperature, and modify the surface of the magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com