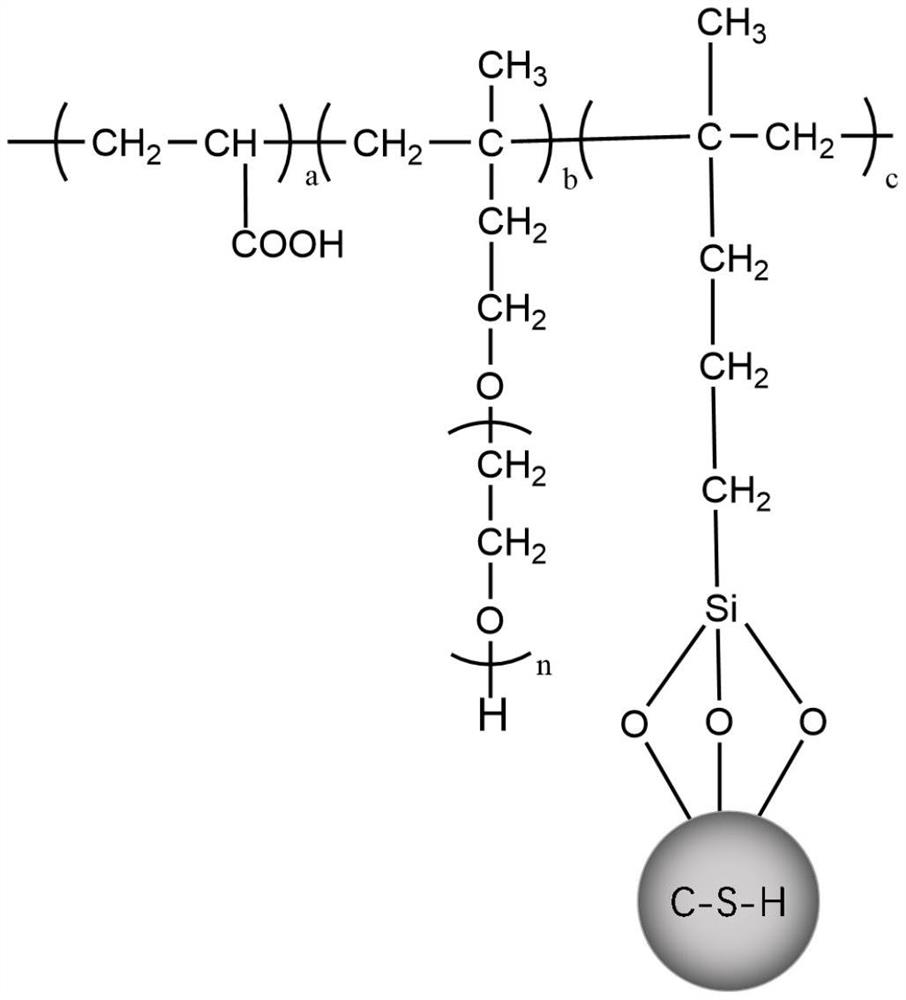

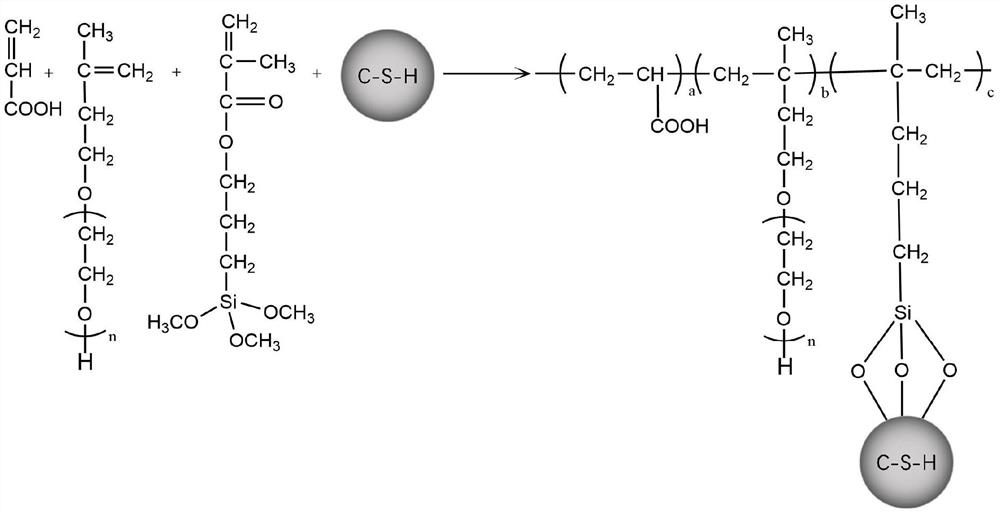

Calcium silicate hydrate crystal nucleus early-strength polycarboxylic acid water reducer and preparation method thereof

A hydrated calcium silicate, early-strength type technology, applied in the field of concrete admixture, can solve the problems affecting the dispersion and adsorption effect of cement slurry, and the reduction of cement particle adsorption, so as to promote the development of early strength and promote rapid hydration , Improve the effect of early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

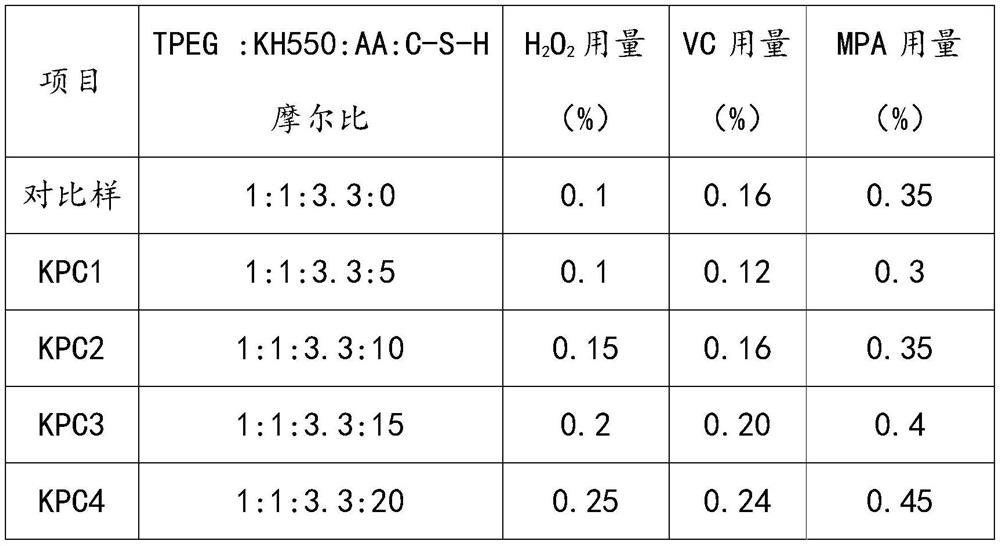

[0035] The preparation method of calcium silicate hydrate crystal nucleus early-strength polycarboxylate superplasticizer of the present invention comprises the following steps:

[0036] S1. Add a designed amount of acrylic acid into water, and stir to obtain solution A;

[0037] S2. Add the designed amount of molecular weight modifier and reducing agent into water, and mix to obtain solution B;

[0038] S3. Dissolve the designed amount of polyether macromonomer in water, and add the designed amount of silane coupling agent (add the silane coupling agent first to make it react more fully, and help to improve the grafting rate of the silane coupling agent) , after mixing, add a designed amount of initiator and react for a period of time;

[0039] S4. Add solution A and solution B dropwise to the solution of S3 at the same time at a certain temperature, and react for a period of time after the dropwise addition to obtain a mixed solution;

[0040] S5. Add the crystal nucleus s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com