Polylactic acid resin as well as preparation method and application thereof

A polylactic acid resin and emulsion technology, which is applied in the field of rubber resin, can solve the problems of reduced viscosity-average molecular weight, high strength loss, and high cost, and achieve the goals of improving impact resistance and bending resistance, enhancing phase interface interaction, and enhancing adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

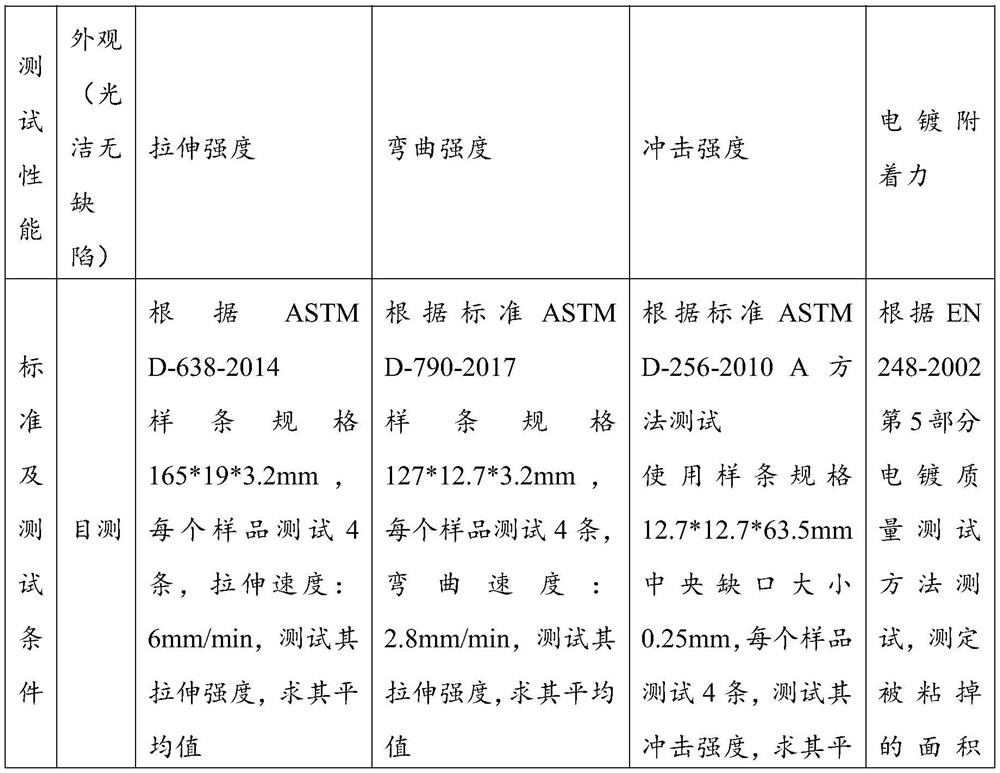

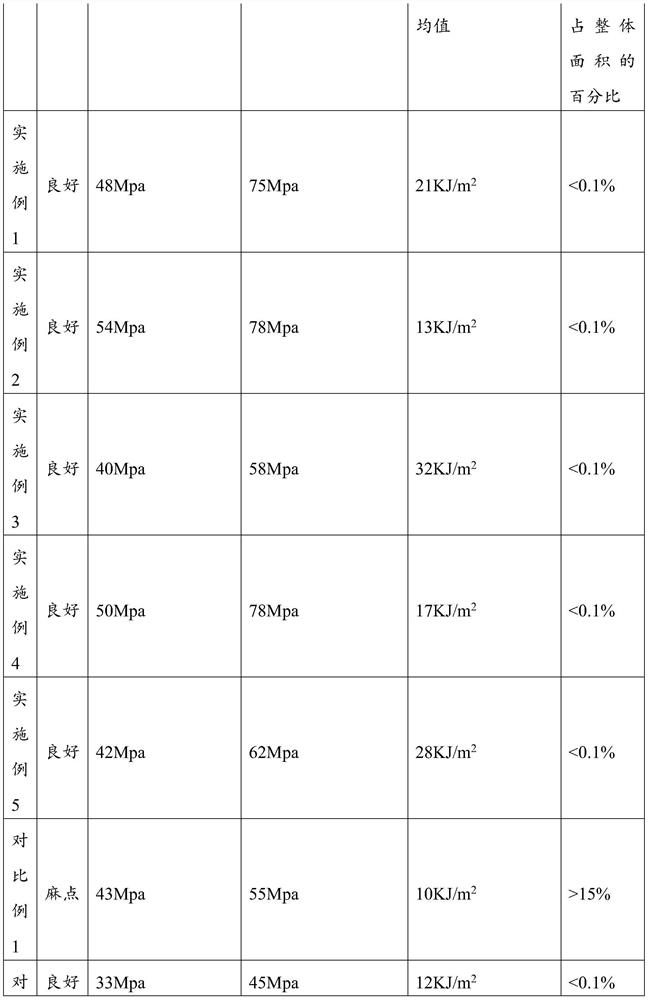

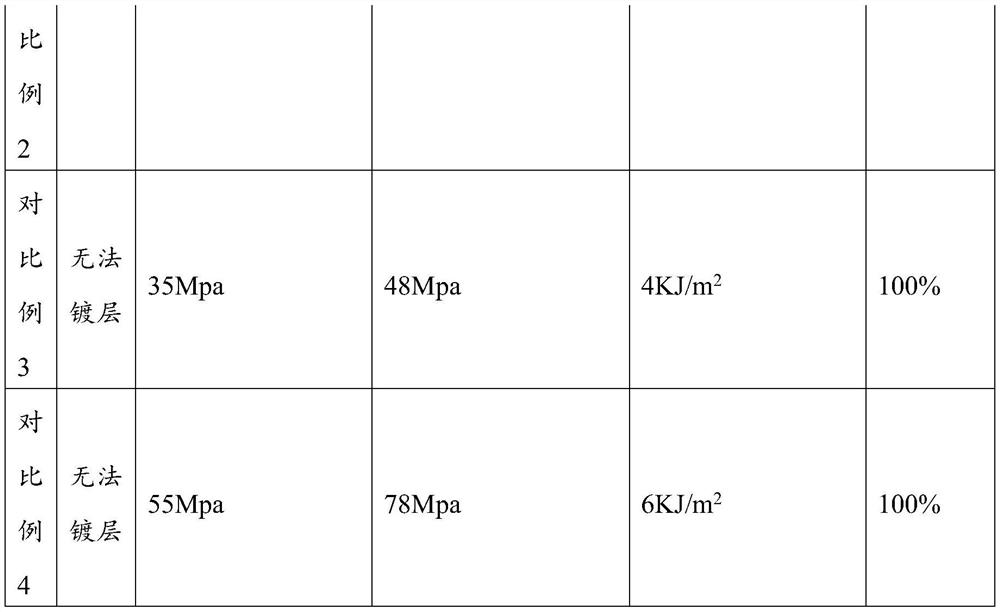

Examples

Embodiment 1

[0027] A kind of polylactic acid (being called for short PLA) resin, its preparation steps are as follows:

[0028] 1) 150g GMA (glycidyl methacrylate), 55g water, 20g potassium stearate, and 10g tert-dodecylmercaptan were added to the container and stirred to obtain the GMA pre-emulsion;

[0029] 2) Add 750g of polybutadiene emulsion (polybutadiene emulsion refers to butadiene self-polyemulsion with solid content of 40wt%, particle size of 300nm, and pH of 11.0) into the reaction vessel, stir and heat up to 65°C;

[0030] 3) Slowly drip the pre-emulsion into the reactor, drop 10g of 10wt% potassium persulfate aqueous solution and 10g of 10wt% sodium thiosulfate aqueous solution at the same time, control the flow rate, and complete the pre-emulsion 4h dropwise, potassium persulfate aqueous solution, sulfur The sodium sulfite aqueous solution was added dropwise 0.5h after the pre-emulsion was dropped to obtain a graft emulsion;

[0031] 4) 100g CaCl 2 Add 900g of water to dis...

Embodiment 2

[0036] A kind of polylactic acid resin, its preparation steps are as follows:

[0037] 1) 50g GMA, 145g water, 1g potassium stearate, 1g tert-dodecylmercaptan are added into the container and stirred to obtain GMA pre-emulsion;

[0038] 2) Add 800g of polybutadiene emulsion (polybutadiene emulsion refers to butadiene self-polyemulsion with solid content of 20wt%, particle size of 100nm, and pH of 13.0) into the reaction vessel, stir and heat up to 80°C;

[0039] 3) Slowly drop the pre-emulsion into the reactor, drop 1g of 10wt% potassium persulfate aqueous solution and 1g of 10wt% sodium thiosulfate aqueous solution at the same time, control the flow rate, and complete the pre-emulsion 2h dropwise, the potassium persulfate aqueous solution, sulfur The sodium sulfite aqueous solution was added dropwise 0.5h after the pre-emulsion was dropped to obtain a graft emulsion;

[0040] 4) 100g MgSO 4 Add 900g of water to dissolve to obtain coagulation solution;

[0041] 5) Heat the ...

Embodiment 3

[0045] A kind of polylactic acid resin, its preparation steps are as follows:

[0046] 1) Add 200g GMA, 200g water, 50g potassium oleate, and 10g tert-dodecylmercaptan into the container and stir to obtain GMA pre-emulsion;

[0047] 2) Add 500g of polybutadiene emulsion (polybutadiene emulsion refers to butadiene self-polyemulsion with solid content of 60wt%, particle size of 600nm, and pH of 7.0) into the reaction vessel, stir and heat up to 50°C;

[0048] 3) Slowly drip the pre-emulsion into the reactor, drop 20 g of 10 wt % potassium persulfate aqueous solution and 20 g of 10 wt % sodium thiosulfate aqueous solution at the same time, control the flow rate, and complete the pre-emulsion 8 h dropwise, potassium persulfate aqueous solution, sulfur The sodium sulfite aqueous solution was added dropwise 0.5h after the pre-emulsion was dropped to obtain a graft emulsion;

[0049] 4) 100g H 2 SO 4 Add 900g of water to dissolve to obtain coagulation solution;

[0050] 5) Heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com