Method of preparing MnWO4/g-C3N4 heterojunction composite photo-catalyst

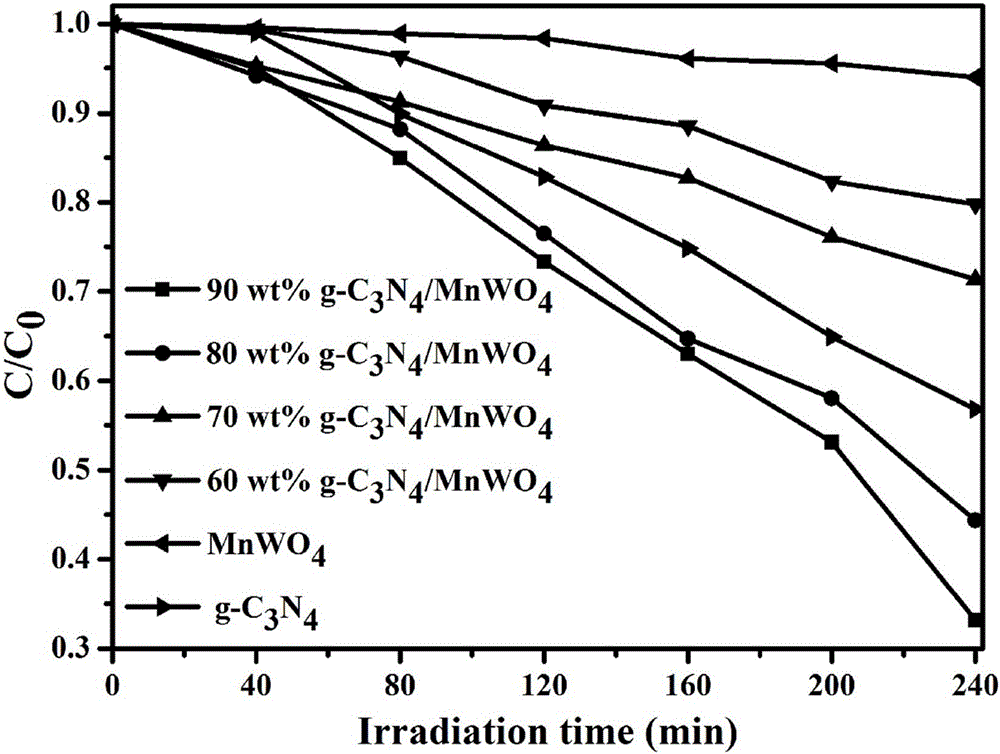

A composite light and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve excellent photocatalytic activity, facilitate mass production, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

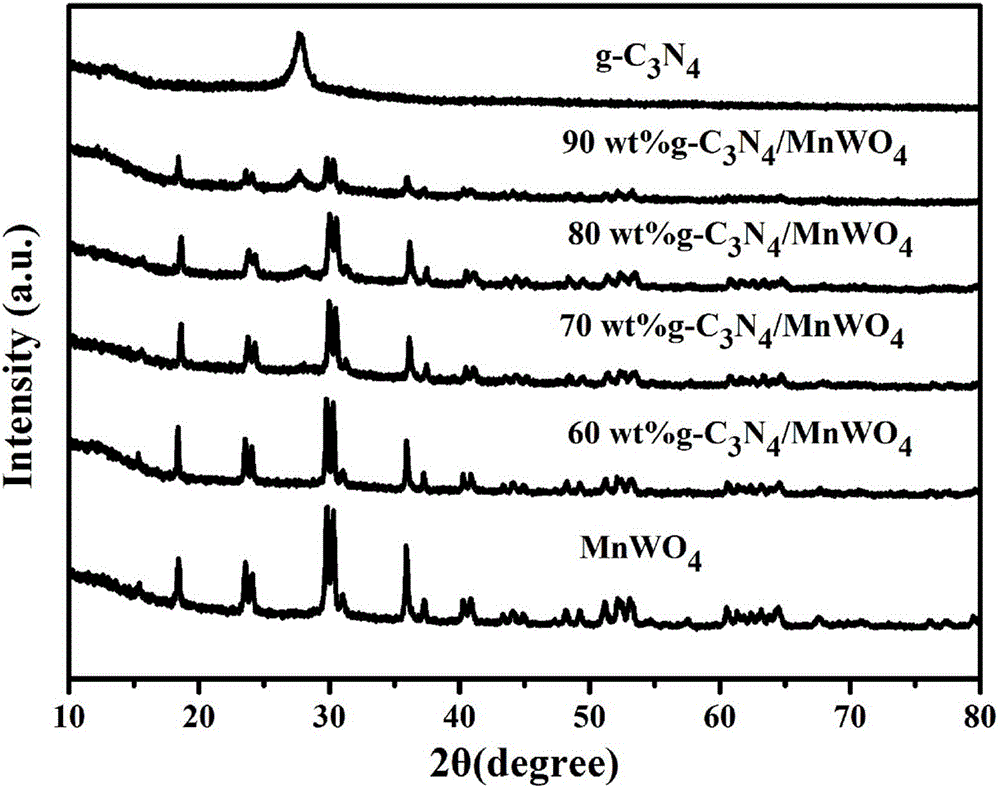

[0021] Weigh 10g of melamine, grind it evenly and place it in a muffle furnace for calcination, set the initial temperature of the muffle furnace to 50°C, raise the temperature of the muffle furnace to 550°C at a heating rate of 2.3°C / min, and react at this temperature for 4h , naturally cooled to room temperature to obtain sample g-C 3 N 4 .

Embodiment example 2

[0023] (1) Weigh 0.164g of sodium tungstate and 0.0989g of manganese chloride and dissolve them in deionized water, and ultrasonically uniform; then slowly add the manganese chloride solution into the sodium tungstate solution with a dropper to obtain white tungsten manganese acid suspension.

[0024] (2) Use 1mol / L sodium hydroxide solution to adjust the pH value of the manganese tungstate solution to 9, then pour the solution into a 50mL hydrothermal kettle, and place the hydrothermal kettle in an oven at 180°C for 12h.

[0025] (3) After cooling to room temperature, centrifuge with ethanol and deionized water respectively to wash away organic and inorganic impurities in the sample, and then dry the obtained sample in an oven at 60°C. Finally got MnWO 4 sample.

Embodiment example 3

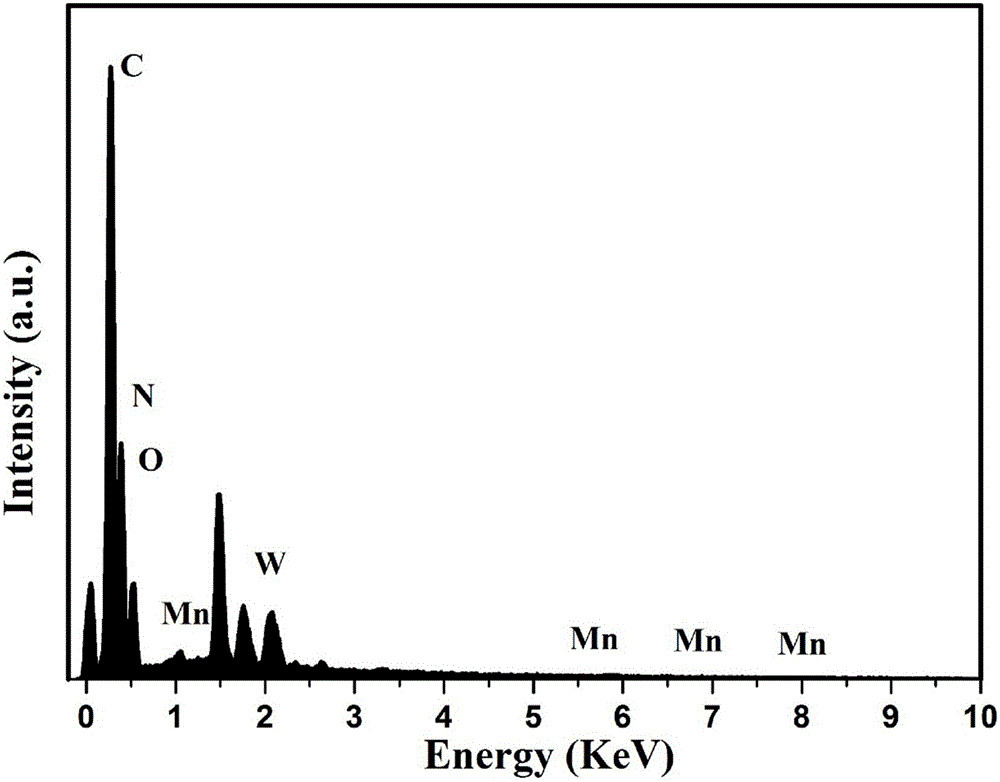

[0027] (1) Weigh 0.164g of sodium tungstate and 0.0989g of manganese chloride and dissolve them in deionized water, and stir until uniform; then slowly add the manganese chloride solution to the sodium tungstate solution with a dropper to obtain White manganese tungstate suspension.

[0028] (2) Weigh 0.228g-C 3 N 4 Add to the white manganese tungstate suspension prepared in step 1, g-C 3 N 4 The mass ratio of manganese tungstate to manganese tungstate is 6:4. After ultrasonication, adjust the pH value of the solution to 9 with 1mol / L sodium hydroxide solution, then pour it into a hydrothermal kettle and place it in an oven. The hydrothermal temperature is 180°C, and the hydrothermal time is 12h. The purpose of hydrothermal is to allow the reactants to synthesize nanocomposites under high temperature and high pressure hydrothermal conditions.

[0029](3) After cooling to room temperature, centrifuge with ethanol and deionized water respectively, and then dry the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com