Composite nano Ag3PO4/TiO2 material with photocatalytic performance prepared by two-step process, and method and application thereof

A composite, photocatalytic technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problems of reduced application value, low utilization of sunlight, etc., to promote rapid transportation and separation. , Solve the effect of high cost and excellent photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

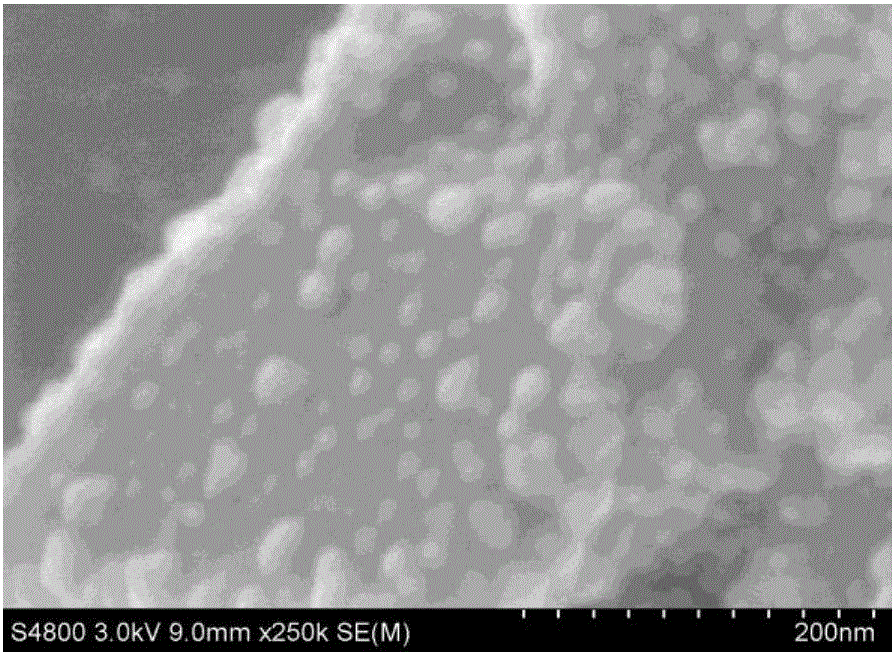

[0041] 2) Nano-Ag 3 PO 4 / TiO 2 preparation of

[0042] Add the rod-shaped titanium dioxide prepared in 1) into distilled water, perform ultrasonic dispersion treatment, then add silver nitrate, then drop a small amount of ammonia water and stir evenly, and finally add Na 2 HPO 4 12H 2 O, after continuing to stir fully for 2.5h, nano-Ag can be obtained 3 PO 4 / TiO 2 solution; the molar ratio of titanium dioxide and silver nitrate is 1: (1 ~ 3), silver nitrate and Na 2 HPO 4 12H 2 The molar ratio of O is 3:1;

[0043] 3) the nano-Ag prepared in 2) 3 PO 4 / TiO 2 Put the solution into the reactor for hydrothermal reaction, then carry out hydrothermal reaction at 100-160°C, after 2-4 hours of hydrothermal reaction, filter, wash, and dry (80-100°C) to obtain nano-Ag 3 PO 4 / TiO 2 particles.

[0044] In order to provide the public with a thorough understanding of the present invention, specific details are specified in the following preferred embodiments of the pres...

Embodiment 1

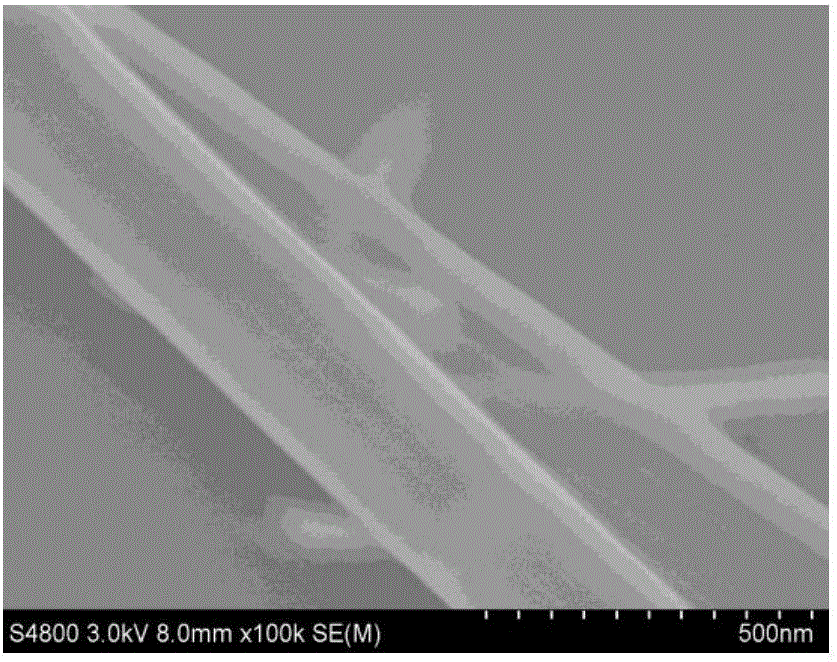

[0046] (1) Ultrasonic disperse 0.25 g of commercially available titanium dioxide P25 particles in 30 mL of 10 mol / L NaOH solution. After 15 min, place the solution in a polytetrafluoroethylene-lined autoclave for 16 h of hydrothermal reaction. After it was naturally cooled to room temperature, it was washed with distilled water and alcohol until it became neutral, then put into a drying oven, and dried at 80°C for 10 hours. The dried sample was added to 0.1mol / L HCI to age for 6 hours, filtered and washed until neutral, dried in a drying oven at 80°C for 10 hours, and then calcined in a muffle furnace at 450°C for 6 hours to make rod-shaped titanium dioxide particles.

[0047] (2) Ultrasonic disperse 72 mg of rod-shaped titanium dioxide prepared in 1) in 25 mL of distilled water, then add 236 mg of silver nitrate, 3-4 drops of NH 3 ·H 2 O stirred for 30min, then added 161mg Na 2 HPO 4 12H 2 O particles continue to stir for 2.5 hours to obtain nano-Ag 3 PO 4 / TiO 2 solut...

Embodiment 2

[0053] (1) Ultrasonic disperse 0.25 g of commercially available titanium dioxide P25 particles in 30 mL of 10 mol / L NaOH solution. After 15 min, place the solution in a polytetrafluoroethylene-lined autoclave for 16 h of hydrothermal reaction. After it was naturally cooled to room temperature, it was washed with distilled water and alcohol until it became neutral, then put into a drying oven, and dried at 80°C for 10 hours. The dried sample was added to 0.1mol / L HCI to age for 6 hours, filtered and washed until neutral, dried in a drying oven at 80°C for 10 hours, and then calcined in a muffle furnace at 450°C for 6 hours to make rod-shaped titanium dioxide particles.

[0054] (2) Ultrasonic disperse 108 mg of rod-shaped titanium dioxide prepared in (1) in 25 mL of distilled water, then add 236 mg of silver nitrate, 3-4 drops of NH 3 ·H 2 O stirred for 30min, then added 161mg Na 2 HPO 4 12H 2 O particles continue to stir for 2.5 hours to obtain nano-Ag 3 PO 4 / TiO 2 sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com