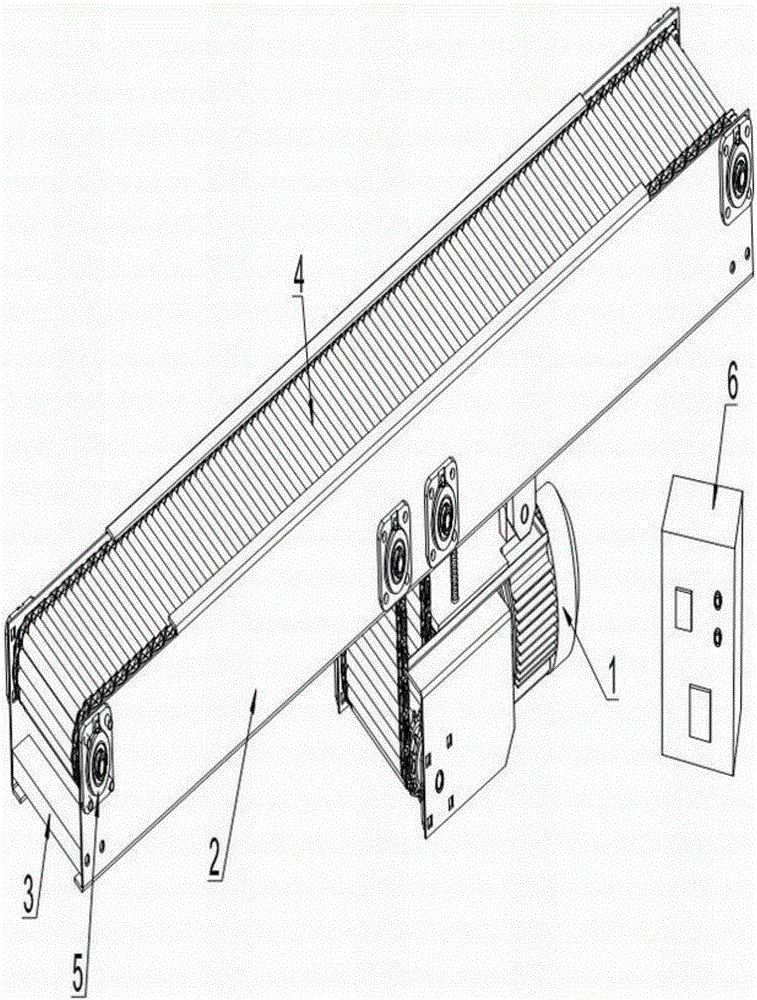

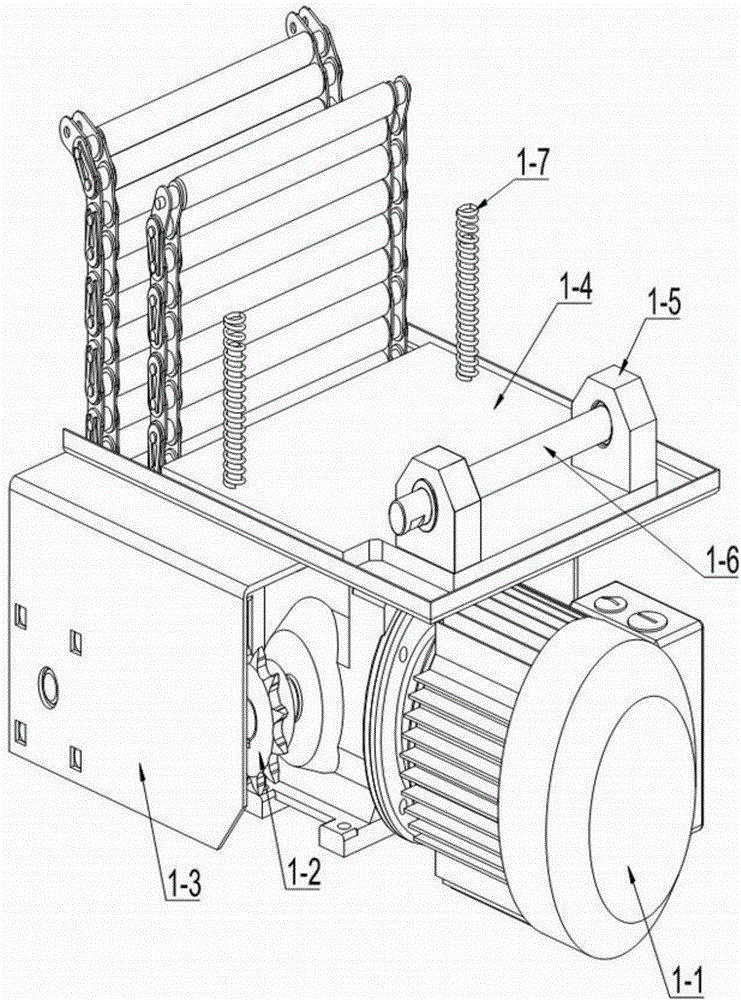

Internal shock absorption type conveying equipment for high-flexibility mortar structural body and engineering principle of internal shock absorption type conveying equipment

A transmission equipment and structure technology, applied in the field of high-flexibility mortar structure built-in shock-absorbing transmission equipment and its engineering principles, can solve the problems of complex control procedures, poor transmission performance, and large footprint, and achieve high safety performance , high rate of increase in wear resistance, and reasonable and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

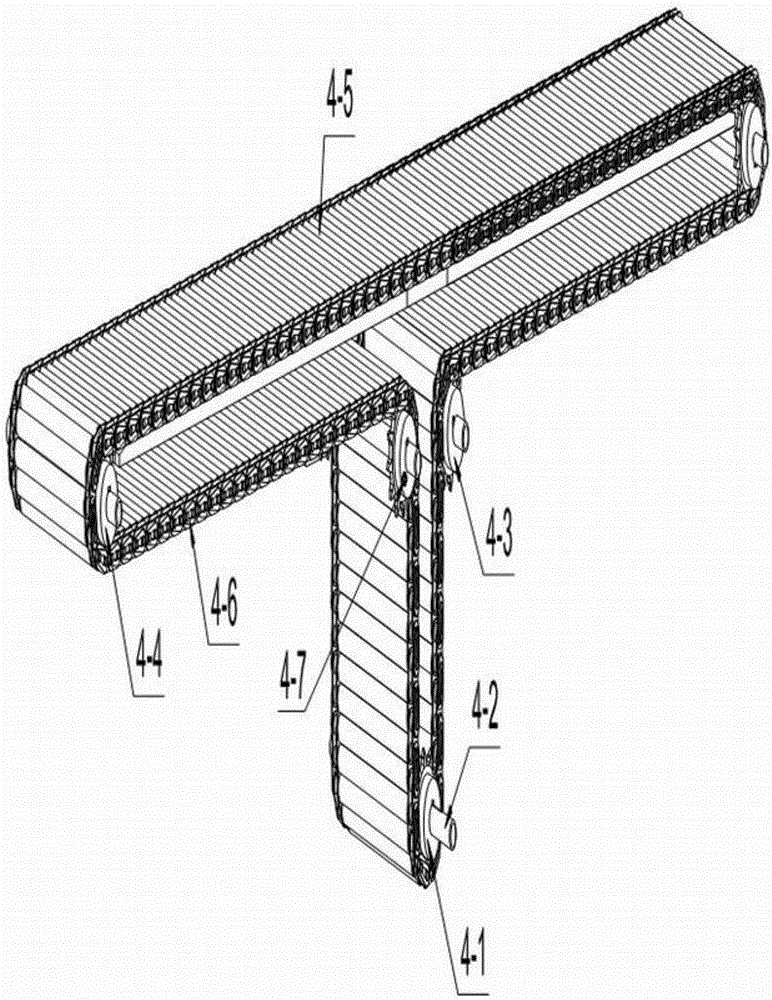

[0045] Manufacture driving roller 4-5 of the present invention according to the following steps, and by weight fraction:

[0046] Step 1: Add 222 parts of ultrapure water with a conductivity of 0.22μS / cm into the reactor, start the stirrer in the reactor at a speed of 102rpm, start the heating pump, and raise the temperature in the reactor to 72°C; Octachloropropyl polyhedral oligomeric silsesquioxane 72 parts, γ-methacryloxypropyl triisopropoxysilane 92 parts, 3-methacryloxypropyl trimethoxysilane 132 parts , stir until completely dissolved, adjust the pH value to 2.2, adjust the speed of the agitator to 122rpm, the temperature is 102°C, and the esterification reaction takes 22 hours;

[0047] Step 2: Take 92 parts of 3-[(2,3)-glycidyloxy]propylmethyldimethoxysilane, 2-(4,6-dimethoxypyrimidine-2-thio)- 82 parts of N-benzamide were pulverized, and the particle size of the powder was 122 meshes; 132 parts of N,N-disubstituted-α-thiocarbonylthioformyl substituted amine were add...

Embodiment 2

[0052] Manufacture driving roller 4-5 of the present invention according to the following steps, and by weight fraction:

[0053] Step 1: Add 1212 parts of ultrapure water with a conductivity of 0.82μS / cm into the reactor, start the stirrer in the reactor at a speed of 222rpm, start the heating pump, and raise the temperature in the reactor to 92°C; Octachloropropyl polyhedral oligomeric silsesquioxane 132 parts, γ-methacryloxypropyl triisopropoxysilane 132 parts, 3-methacryloxypropyl trimethoxysilane 332 parts , stir until completely dissolved, adjust the pH value to 8.2, adjust the speed of the agitator to 222rpm, the temperature is 172°C, and the esterification reaction is 32 hours;

[0054] Step 2: Take 202 parts of 3-[(2,3)-glycidyloxy]propylmethyldimethoxysilane, 2-(4,6-dimethoxypyrimidine-2-thio)- 132 parts of N-benzamide were pulverized, and the particle size of the powder was 222 meshes; 332 parts of N,N-disubstituted-α-thiocarbonylthioformyl substituted amines were ...

Embodiment 3

[0059] Manufacture driving roller 4-5 of the present invention according to the following steps, and by weight fraction:

[0060] Step 1: Add 912 parts of ultrapure water with a conductivity of 0.62μS / cm into the reactor, start the stirrer in the reactor at a speed of 172rpm, start the heating pump, and raise the temperature in the reactor to 82°C; Octachloropropyl polyhedral oligomeric silsesquioxane 102 parts, γ-methacryloxypropyl triisopropoxysilane 112 parts, 3-methacryloxypropyl trimethoxysilane 232 parts , stir until completely dissolved, adjust the pH value to 4.2, adjust the speed of the agitator to 182rpm, the temperature is 142°C, and the esterification reaction takes 26 hours;

[0061] Step 2: Take 102 parts of 3-[(2,3)-glycidyloxy]propylmethyldimethoxysilane, 2-(4,6-dimethoxypyrimidine-2-thio)- 102 parts of N-benzamide were crushed, and the particle size of the powder was 172 meshes; 232 parts of N,N-disubstituted-α-thiocarbonyl thioformyl substituted amine were a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com