Method for preparing PbS nanosheet by using self-assembly

A nanosheet and self-assembly technology, applied in the field of nanomaterials, can solve the problems of limited application of electronic devices, difficult monodispersity, small size of PbS nanosheets, etc., achieving simple operation, easy transfer to any substrate, and simple and easy operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] (a) Preparation of PbS spherical nanoparticles

[0068] Put 180mg of lead oxide, 8mL of oleic acid and 8mL of octadecene in a 50mL three-necked flask, heat it to 120°C, remove water and air in a vacuum, and after 2h, inject nitrogen gas, raise the temperature of the solution to 130°C, and quickly inject the solution There is 82 μL of hexamethyldisilathane in 4 mL of octadecene solution, and the temperature of the solution is lowered to 100° C. for 20 minutes. After the reaction stopped, the PbS nanoparticles were precipitated twice with absolute ethanol, and the PbS spherical nanoparticles were dispersed in an octane solvent and placed in a glove box for later use.

[0069] (b) Preparation of PbS cubic nanoparticles

[0070] Take 10 mL of the above-mentioned PbS spherical nanoparticles in a 50 mL single-necked bottle, add 10 mL of oleic acid solution, and react at 90° C. for 1 h, and the reaction is carried out in a glove box. The obtained nanoparticles are precip...

Embodiment 1

[0073] (1) Disperse PbS cubic nanoparticles in octane solvent, take 30 μL octane solution of PbS cubic nanoparticles and disperse them in 420 μL n-hexane solvent, add 1.2 μL oleic acid, mix well, and quickly drop the mixed solution to On the liquid surface of 6mL diethylene glycol, a PbS monolayer supercrystalline film was formed after 1h.

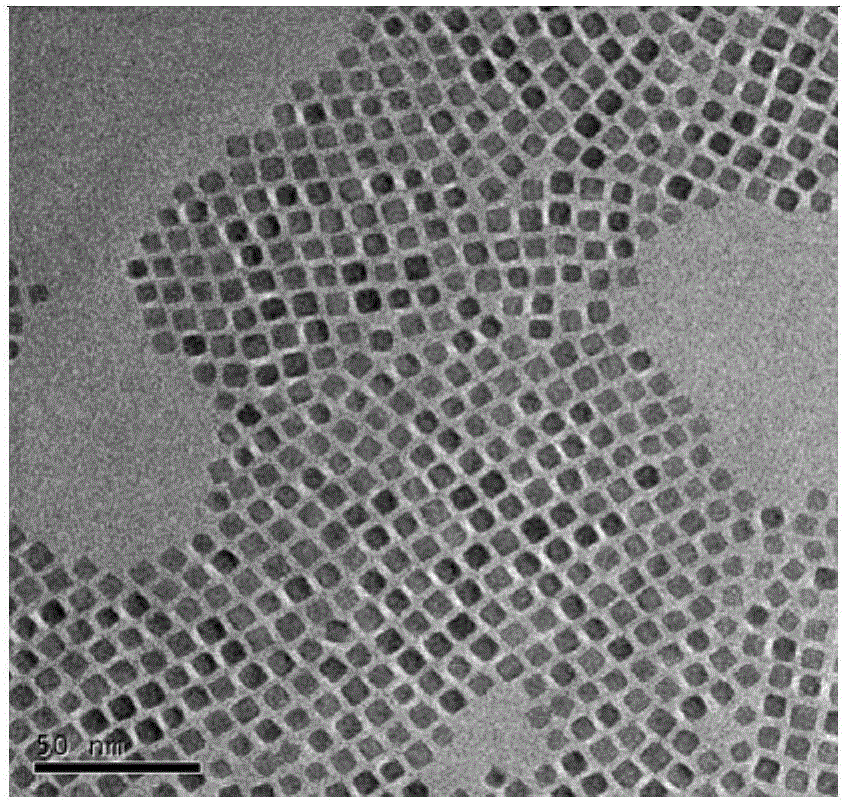

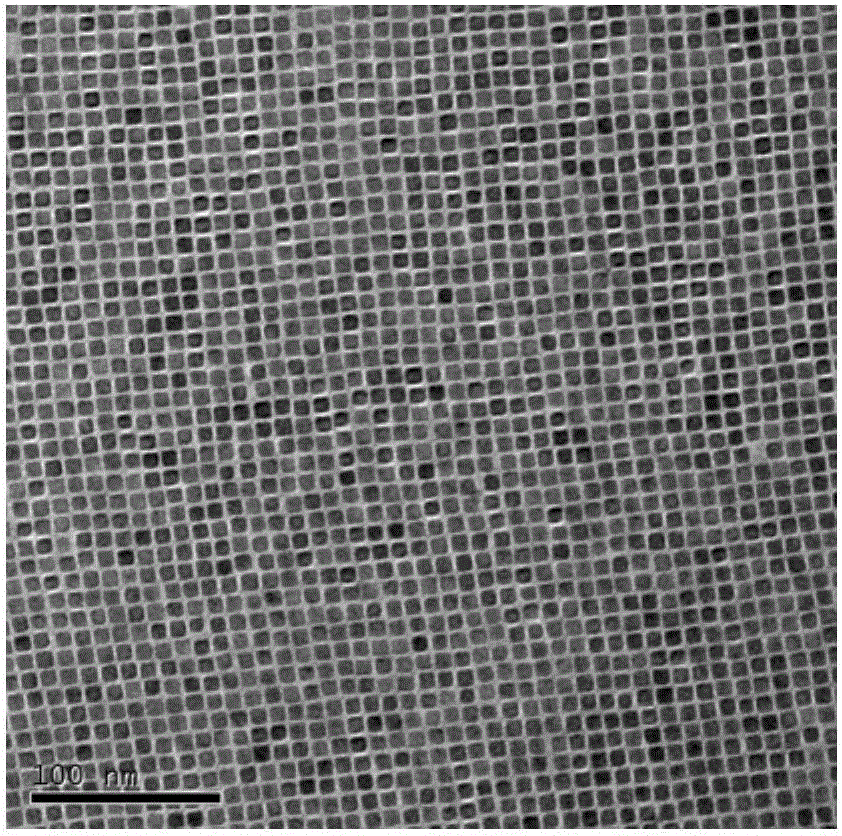

[0074] figure 2 It is a transmission electron microscope image of the PbS supercrystalline thin film prepared by the above method.

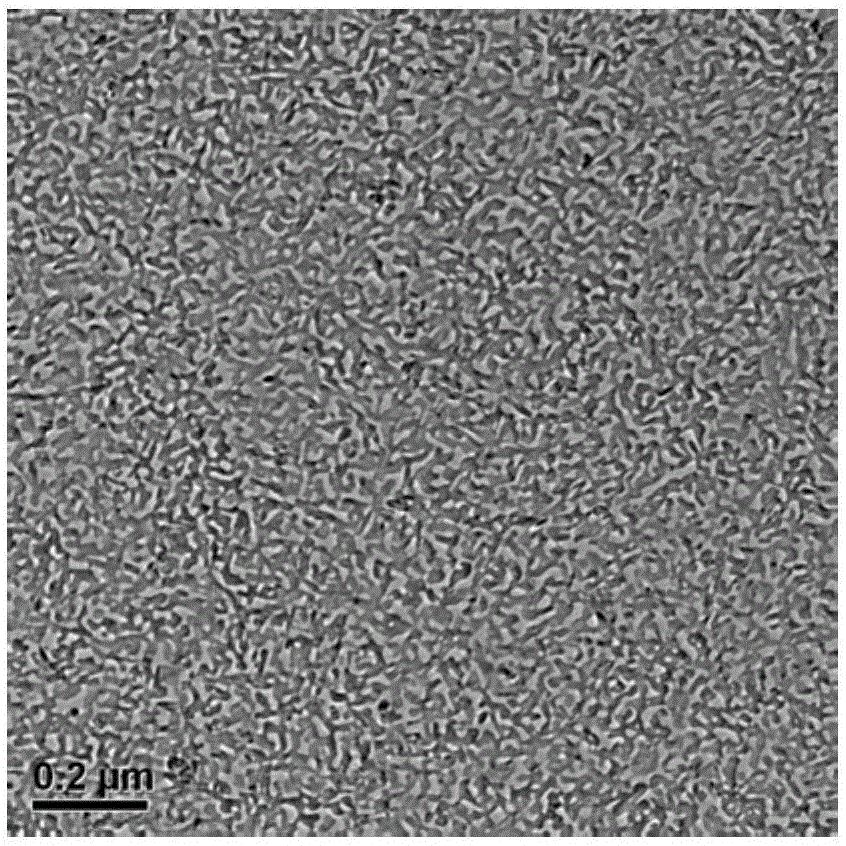

[0075] (2) The formed PbS single-layer supercrystalline film and its lower phase 6mL diethylene glycol solution were placed on a hot stage at 50° C. for 1 h to prepare PbS nanosheets.

Embodiment 2

[0077] (1) is the same as step (1) of embodiment 1.

[0078] (2) The formed PbS single-layer supercrystalline film and 6 mL of diethylene glycol solution as the lower phase were placed on a hot stage at 100° C. for 1 h to prepare PbS nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com