Vinyl-sulfone type reactive disperse dye for supercritical CO2 and preparation method and application thereof

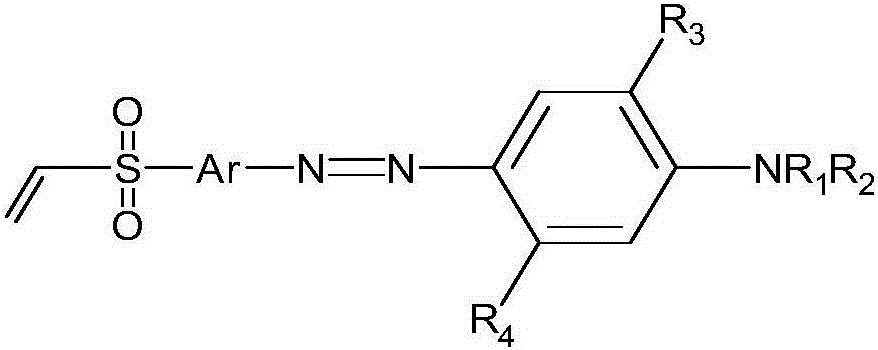

A reactive disperse dye, vinyl sulfone type technology, applied in reactive dyes, dyeing methods, organic dyes, etc., can solve problems such as difficult application of supercritical dyeing, achieve good industrialization prospects, small molecular weight, and reduce the degree of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

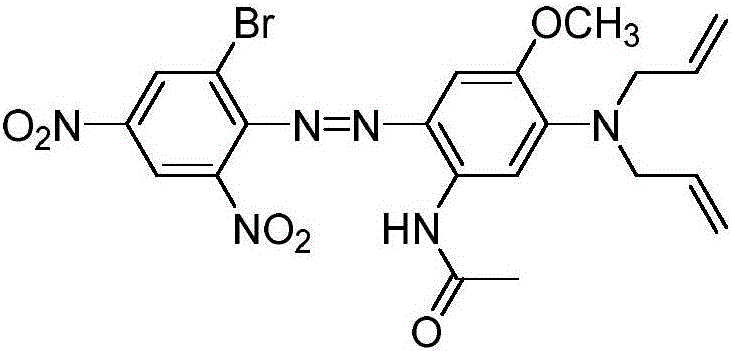

[0043] Compound 1:

[0044]

[0045](1) Weigh 2-methoxy-4-acetamidoaniline (18.1g, 0.1mol), add 300ml DMF, stir to dissolve, add Na 2 CO 3 (21.2g, 0.2mol), tetra-n-butylammonium bromide (3.22g, 0.001mol), the temperature was raised to 90°C, and allyl bromide (36.3g, 0.3mol) was slowly added dropwise, kept for 2h, and the reaction was detected by TLC After the reaction is complete, add 300ml of water, extract with dichloromethane (30ml×3), wash with water, dry the organic phase, and rotary evaporate to obtain 22.76g of brown-black solid with a yield of 87.54%.

[0046] (2) Weigh p-vinylsulfone aniline (10.98g, 0.06mol), add 40g of water, add 36% HCl (18.25g, 0.18mol), heat up to 50°C, stir and dissolve into a brown-black solution, cool to 0- 5°C, weigh NaNO 2 (4.14g, 0.06mol) was made into a 30% solution, slowly added dropwise to the reaction solution, and reacted for 30min to obtain a yellow and clear diazonium solution.

[0047] (3) Weigh the product (16.38g, 0.063mol)...

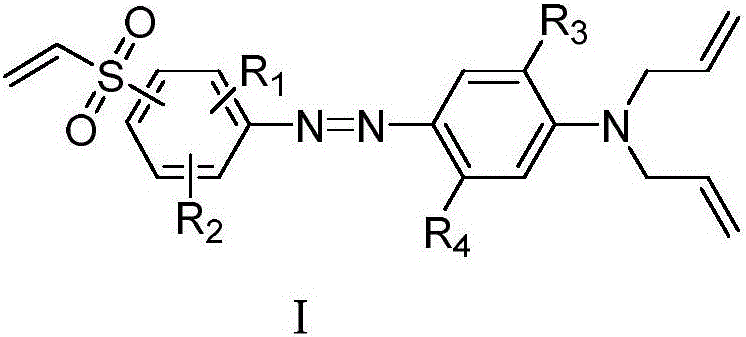

Embodiment 2-6

[0049] Examples 2-6 were prepared according to the method of Example 1, as shown in Table 1.

[0050] Table 1

[0051]

Embodiment 7

[0053] Compound 7:

[0054]

[0055] (1) Weigh 2-ethoxy-4-propionamidoaniline (20.8g, 0.1mol), add 400ml DMF, stir to dissolve, add Na 2 CO 3 (30.9g, 0.3mol), add benzyltriethylammonium chloride (2.27g0.01mol), heat up to 65°C, slowly add allyl bromide (48.4g, 0.4mol), keep warm for 2h, and detect with TLC After the reaction was complete, 300ml of water was added, extracted with acetone (30ml×3), washed with water, the organic phase was dried, and rotary evaporated to obtain 25.83g of a brown-black solid with a yield of 89.71%.

[0056] (2) Weigh 2,6-dibromo-4-vinylsulfoneaniline (10.83g, 0.03mol), dissolve it in 40g of concentrated sulfuric acid, stir and dissolve into a dark red solution, slowly add 37% nitrosylsulfuric acid solution dropwise (9.52g, 0.03mol), and kept stirring for 30min to obtain a dark brown diazonium solution.

[0057] (3) Weigh the product (8.64g, 0.03mol) in step (1), add 30mlCH 3 COOH, add 30gCH 3 Add 300 g of ice water to COONa, stir, and slow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap