Environment-friendly type biofuel

A kind of biofuel and environment-friendly technology, applied in the field of environment-friendly biofuel, can solve the problem of low tail gas emission, achieve low tail gas emission, stable performance, and solve the effect of rubber swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

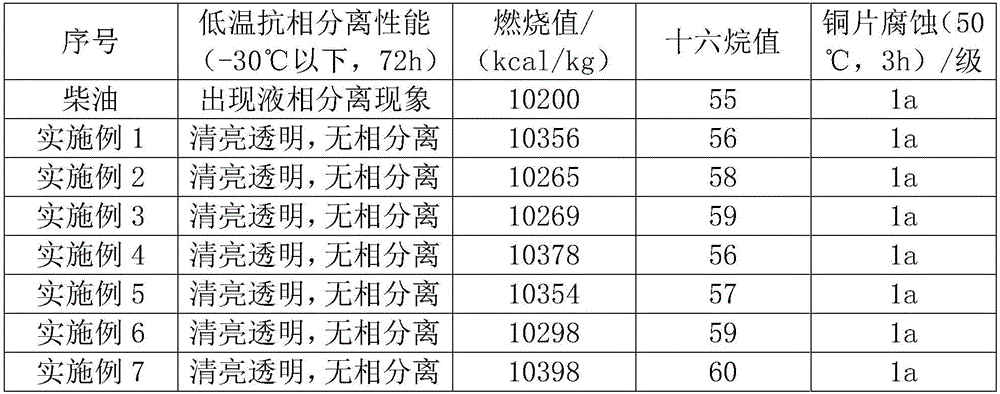

Examples

Embodiment 1

[0023] Environmentally friendly biofuel, made from the following raw materials in parts by weight: 15 parts of ethanol, 10 parts of propanol, 33 parts of castor oil, 10 parts of n-octane, 14 parts of glyceryl triacetate, 6 parts of sodium dodecylbenzenesulfonate parts, 2.6 parts of additives; the additives are 10 parts by weight of 3,4,5-trihydroxybenzoic acid propyl ester, 20 parts by weight of tributyl phosphate, 0.1 parts by weight of liquid paraffin, 12 parts by weight of fatty acid diethanolamide and 8 parts by weight A mixture of combustion-supporting agents in parts by weight; the combustion-supporting agent is a mixture of methyl tert-butyl ether and dipentyl iron in a mass ratio of 9:1.

[0024] The preparation method of the above-mentioned environment-friendly biofuel is as follows: mix all raw materials evenly, stir at 30° C. for 50 minutes, let stand for 10 hours, and filter.

Embodiment 2

[0026] Environmentally friendly biofuel, made from the following raw materials in parts by weight: 20 parts of methanol, 9 parts of amyl alcohol, 30 parts of castor oil, 12 parts of n-octane, 13 parts of glyceryl triacetate, 7 parts of sodium dodecylbenzenesulfonate parts, 2.3 parts of additives; the additives are 12 parts by weight of 3,4,5-trihydroxybenzoic acid propyl ester, 18 parts by weight of tributyl phosphate, 0.2 parts by weight of liquid paraffin, 11 parts by weight of fatty acid diethanolamide and 9 A mixture of combustion-supporting agents in parts by weight; the combustion-supporting agent is a mixture of methyl tert-butyl ether and dipentyl iron in a mass ratio of 8:1.

[0027] The preparation method of the above-mentioned environment-friendly biofuel is as follows: mix all raw materials evenly, stir at 35° C. for 45 minutes, let stand for 11 hours, and filter.

Embodiment 3

[0029] Environmentally friendly biofuel, made from the following raw materials in parts by weight: 23 parts of methanol, 10 parts of butanol, 27 parts of castor oil, 14 parts of n-octane, 12 parts of glyceryl triacetate, 8 parts of sodium dodecylbenzenesulfonate parts, 2.1 parts of additives; the additives are 14 parts by weight of 3,4,5-trihydroxybenzoic acid propyl ester, 16 parts by weight of tributyl phosphate, 0.3 parts by weight of liquid paraffin, 10 parts by weight of fatty acid diethanolamide and 10 parts by weight A mixture of combustion-supporting agents in parts by weight; the combustion-supporting agent is a mixture of methyl tert-butyl ether and dipentyl iron in a mass ratio of 7:1.

[0030] The preparation method of the above-mentioned environment-friendly biofuel is as follows: mix all raw materials evenly, stir at 40° C. for 40 minutes, let stand for 12 hours, and filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com