Novel control method for deep liquid fermentation of agaricus brunnescens peck polysaccharide

A technology of deep liquid fermentation and mushroom polysaccharides, applied in fermentation and other fields, can solve the problems that restrict the production efficiency of brown mushroom polysaccharides, and achieve the effect of dissolved oxygen and nutrient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A novel method for controlling brown mushroom polysaccharide submerged liquid fermentation, comprising the following steps:

[0021] 1) Strain activation: transfer the brown mushroom strain (ACCC51579, China Agricultural Microorganism Strain Collection and Management Center) into the solid medium slope of the test tube, and put it into a constant temperature incubator at 25°C to cultivate until the tube is full.

[0022] Slope medium (g / L): glucose 20, peptone 2, potassium dihydrogen phosphate 1, magnesium sulfate heptahydrate 1.5, vegetable garden soil 600, wheat grain 100, agar 25, after preparation, sterilize at 121°C for 20 minutes.

[0023] 2) Preparation of seed liquid: take 3 pieces of 0.5cm 2 The fresh slant strains were inoculated into the seed medium (100mL / 500mL Erlenmeyer flask), cultured on a shaker at 25°C and 150r / min for 5 days, and sterilized at 121°C for 20min after preparation.

[0024] Seed medium (g / L): Glucose 20, peptone 2, potassium dihydrogen p...

Embodiment 2

[0028] A novel method for controlling brown mushroom polysaccharide submerged liquid fermentation, comprising the following steps:

[0029] 1) Strain activation: transfer the brown mushroom strain (ACCC51579, China Agricultural Microorganism Strain Collection and Management Center) into the solid medium slope of the test tube, and put it into a constant temperature incubator at 25°C to cultivate until the tube is full. Slope medium (g / L): glucose 20, peptone 2, potassium dihydrogen phosphate 1, magnesium sulfate heptahydrate 1.5, vegetable garden soil 600, wheat grain 100, agar 25.

[0030] 2) Preparation of seed liquid: take 3 pieces of 0.5cm 2 The fresh slant strains were inoculated into the seed medium (100mL / 500mL Erlenmeyer flask), cultured on a shaker at 25°C and 150r / min for 5 days.

[0031] Seed medium (g / L): glucose 20, peptone 2, potassium dihydrogen phosphate 2, magnesium sulfate heptahydrate 1, glutamine 0.1.

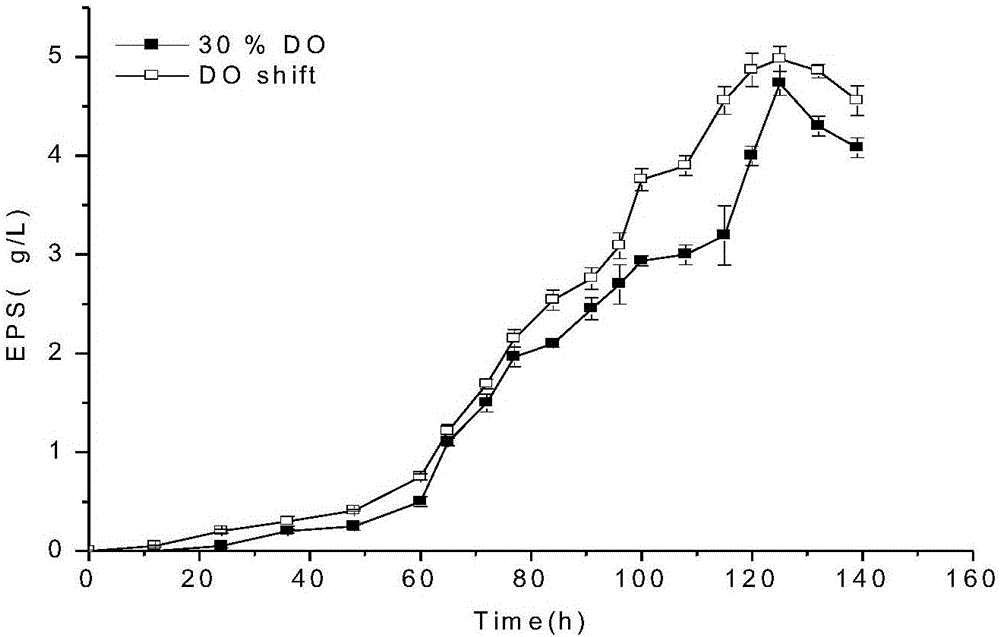

[0032] 3) The control method of high-efficiency brow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com