Disc type solar coupling SOEC (solid oxide electrolysis cell) electrolysis hydrogen production equipment and hydrogen production method

A kind of hydrogen production equipment and solar energy technology, which is applied in the field of solar heat collection and electrolytic hydrogen production, can solve the problems of low heat conversion rate, influence on hydrogen price, low hydrogen production efficiency, etc., achieve low pollution, improve energy distribution, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

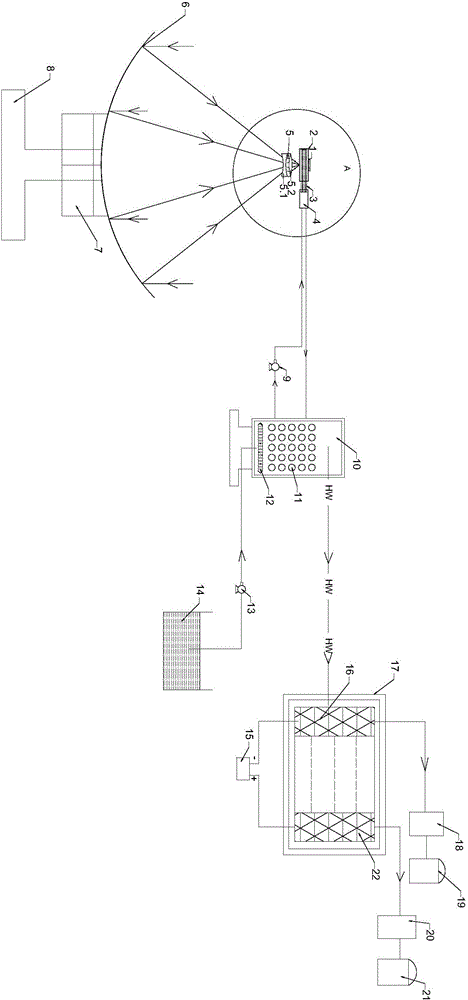

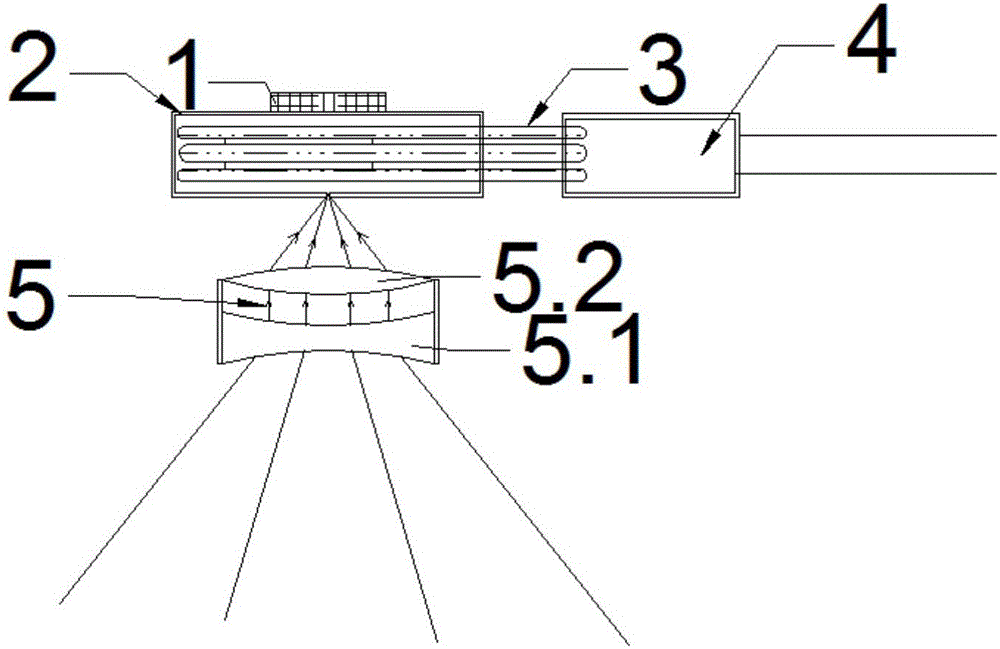

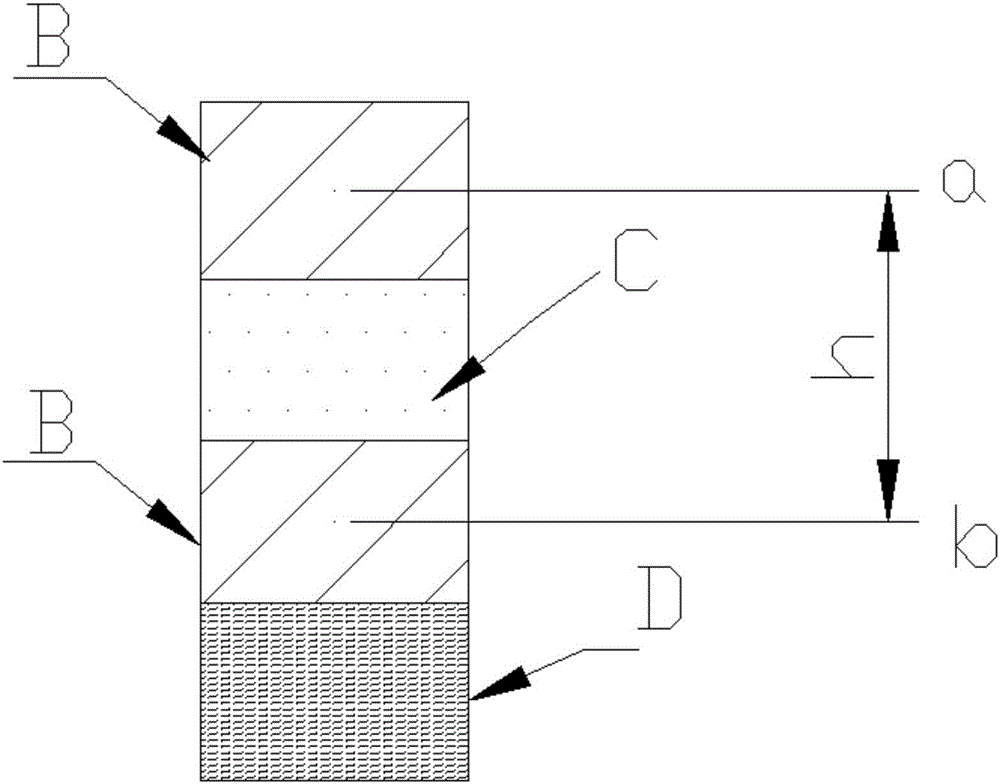

[0039] like Figure 1-2 As shown, a dish-type solar energy coupling SOEC electrolytic hydrogen production equipment includes a light intensity sensor 1, and the light intensity sensor 1 is arranged on a heat collector 2, and a concentrator 5 is provided at the bottom of the heat collector 2, The bottom of concentrator 5 is provided with dish-type light-condensing reflector 6, and described dish-type light-condensate reflector 6 is located on the daily dynamic bearing box 7, and described daily dynamic bearing box 7 is located on the base 8; The light intensity sensor 1 is connected with the controller in the described daily dynamic bearing box 7;

[0040] The heat collector 2 is connected to the liquid metal heat exchanger 4 through the tube-type heat pipe 3, and the liquid metal heat exchanger 4 is connected to the heat exchanger 10, and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com