Manufacturing method and product of metal solder mask for high-density microwave circuit assembly

A technology of microwave circuits and manufacturing methods, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as cracking and substrate warping, and achieve the effects of good process compatibility and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the present invention, the present invention is described below in conjunction with specific examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

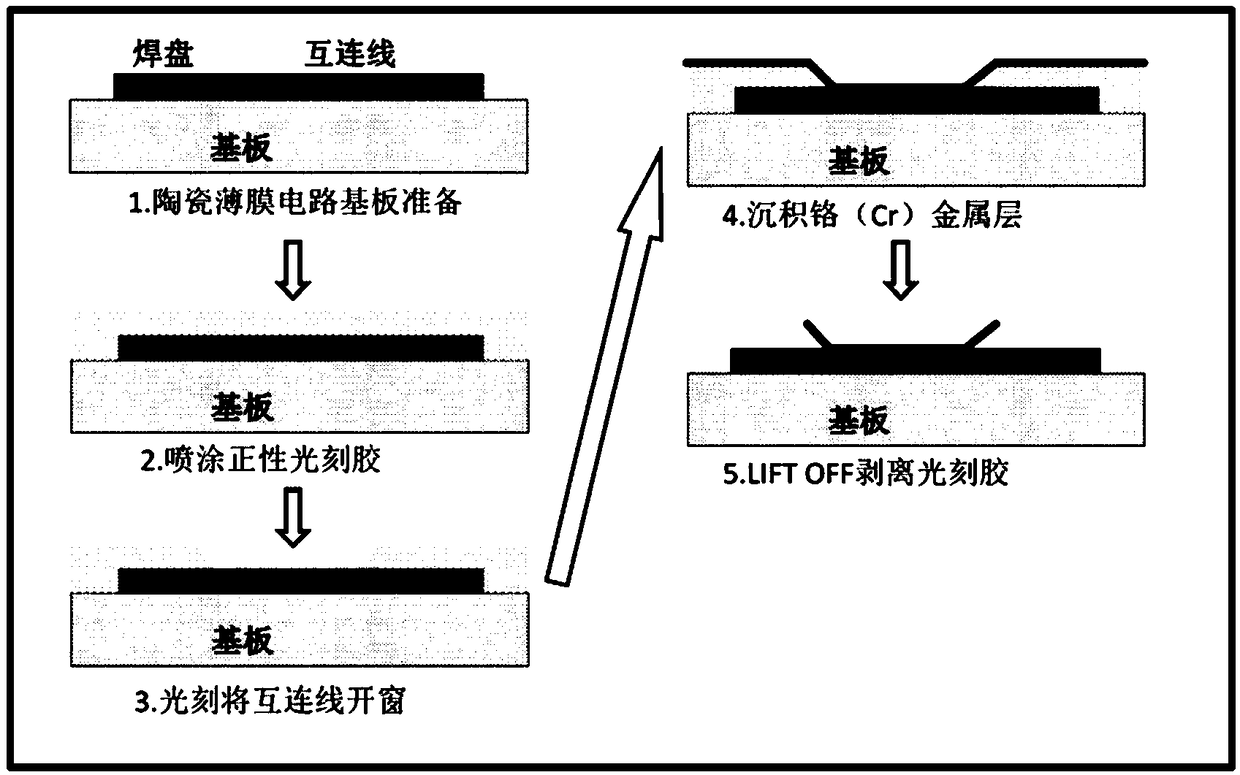

[0042] see image 3 A method for manufacturing a metal solder mask for high-density microwave circuit assembly, comprising the following steps:

[0043] Step 1: Clean the substrate. Clean the surface of the microwave circuit substrate to remove surface dirt.

[0044] Step 2: Spray photoresist. Spray photoresist over the pads and interconnect lines of the substrate.

[0045] Step 3: Open the window by photolithography. Alignment UV lithography was performed, developed to remove the photoresist above the transmission line, and the surface was cleaned by reactive ion etching with oxygen plasma.

[0046] Step 4: Deposit a metal layer. A met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com