Recycling method of lithium-ion battery

A lithium-ion battery, recycling technology, applied in the field of lithium-ion batteries, can solve the problems of short time consumption and high cost, and achieve the effects of short time consumption, easy recycling, and elimination of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

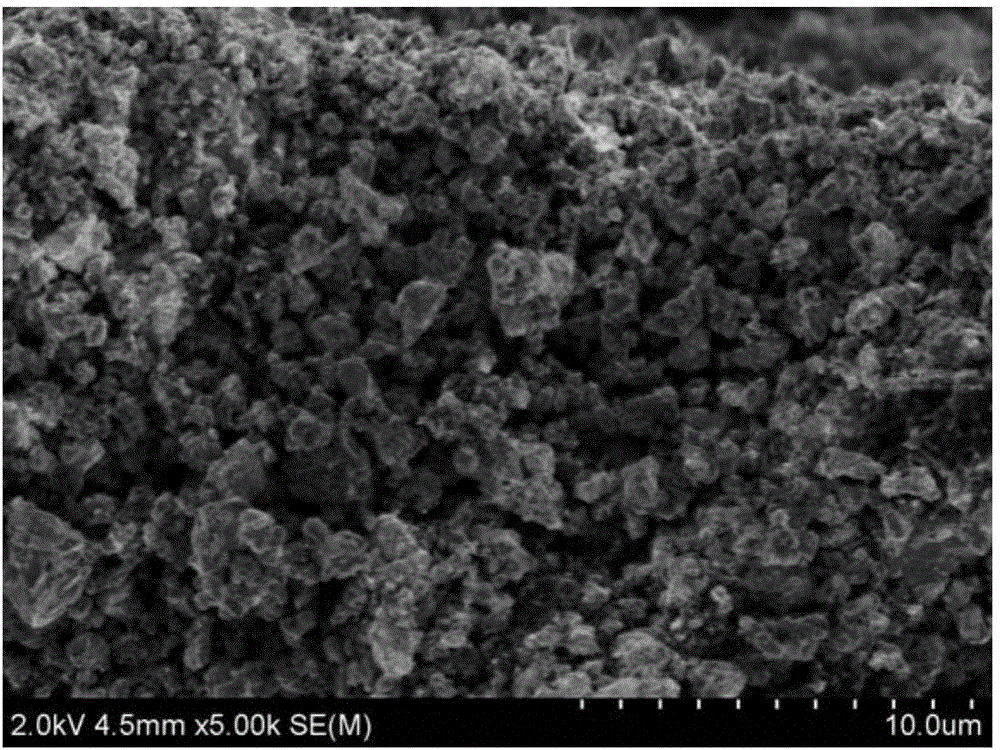

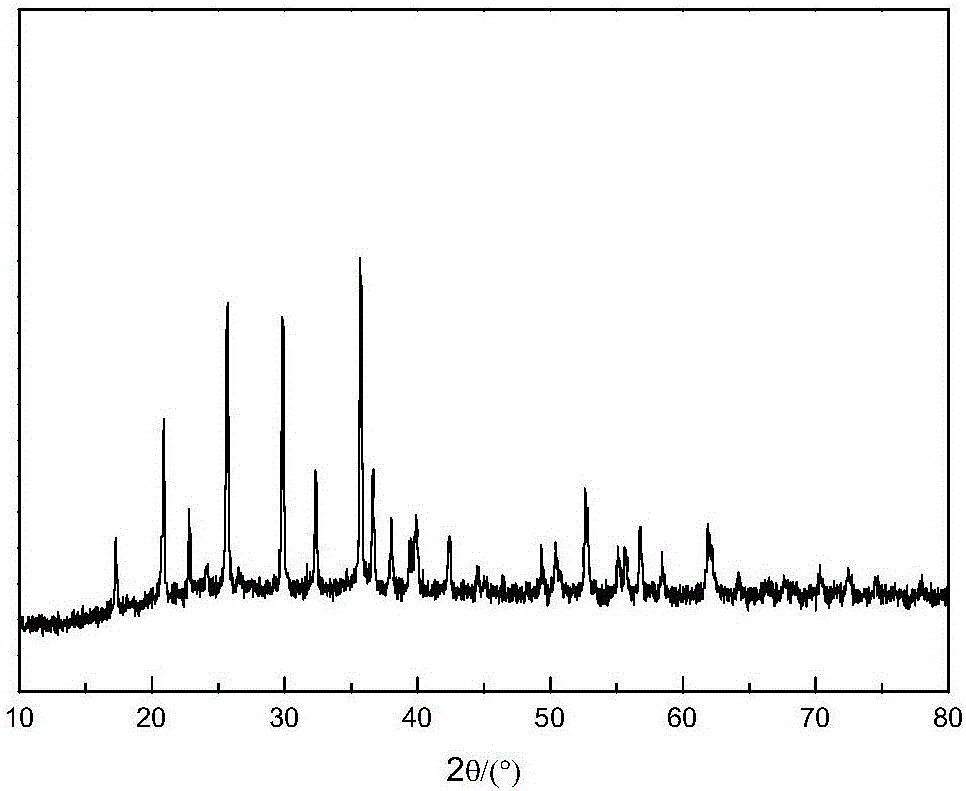

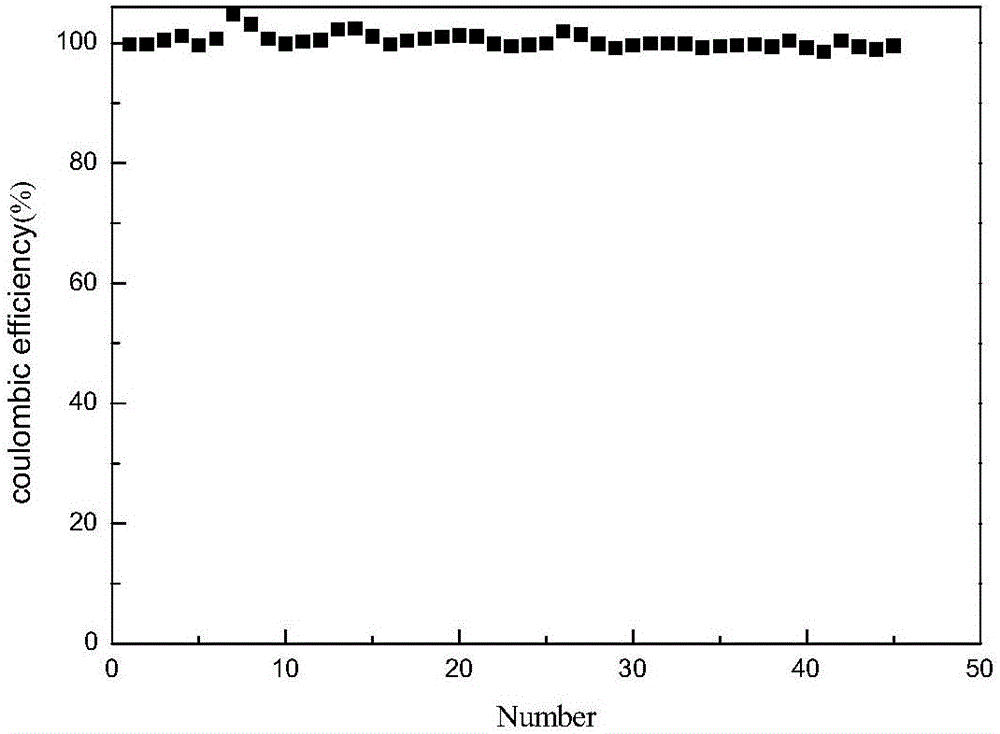

[0030] Example 1: For a lithium iron phosphate battery after discharge treatment, cut the disassembled positive electrode sheet into 2cm*2cm pieces, place them in a muffle furnace with a gas collection device, and step by step under the protection of an inert gas argon Heating, the temperature is raised from room temperature to 90° C. at a rate of 5° C. / min. After 1 hour of heat preservation, the temperature is raised to 400° C. at a rate of 5° C. / min. and kept at a temperature of 1.5 hours. The gas volatilized from the muffle furnace is absorbed and reacted with 1mol / L sodium hydroxide to eliminate the toxicity of volatiles. Stir the heated positive electrode sheet in 100mL 1mol / L sodium hydroxide solution for 5min until the aluminum foil and electrode material are completely separated, then take out the aluminum foil and recycle it directly. After the collected electrode materials were washed with water three times, they were dried at 90° C. to obtain 12 g of electrode mater...

Embodiment 2

[0031] Example 2: For a lithium iron phosphate battery that has undergone discharge treatment, cut the disassembled positive electrode sheet into 2cm*2cm pieces, place them in a muffle furnace with a gas collection device, and step by step under the protection of an inert gas argon Heating, the temperature is raised from room temperature to 80° C. at a rate of 5° C. / min. After 1.5 hours of heat preservation, the temperature is raised to 370° C. at a rate of 5° C. / min. and kept at a temperature of 2 hours. The gas volatilized from the muffle furnace is absorbed and reacted with 1mol / L sodium hydroxide to reduce the toxicity of volatiles. Stir the heated electrode sheet in 100mL 1mol / L sodium hydroxide solution for 10min until the aluminum foil and the electrode material are completely separated, then take out the aluminum foil directly. After the collected electrode material was washed three times with water, it was dried at 90° C. to obtain 14 g of electrode material. After d...

Embodiment 3

[0032] Example 3: For the lithium iron phosphate battery after discharge treatment, the disassembled positive electrode sheet is cut into 2cm*2cm pieces, placed in a muffle furnace with a gas collection device, heated step by step under air conditions, the temperature The temperature was raised from room temperature to 100° C. at a rate of 5° C. / min and kept at a rate of 1 hour, then raised to 450° C. at a rate of 5° C. / min and kept at a rate of 1 hour. The gas volatilized from the muffle furnace is absorbed and reacted with 1mol / L sodium hydroxide to reduce the toxicity of volatiles. Stir the heated electrode sheet in 100mL 1mol / L sodium hydroxide solution for 10min until the aluminum foil and the electrode material are completely separated, then take out the aluminum foil directly. The collected electrode materials were washed with water three times, and then dried at 90° C. to obtain 16.5 g of electrode materials. The collected electrode material is Li 3 Fe(PO 4 ) 2 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com