Carbon aerogel electrode dedicated for capacitive deionization device and preparation method thereof

A technology of capacitive deionization and carbon airgel, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as complicated processes, increased electrode manufacturing costs, and reduced airgel electrosorption performance. The effect of simple process, high mechanical strength and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

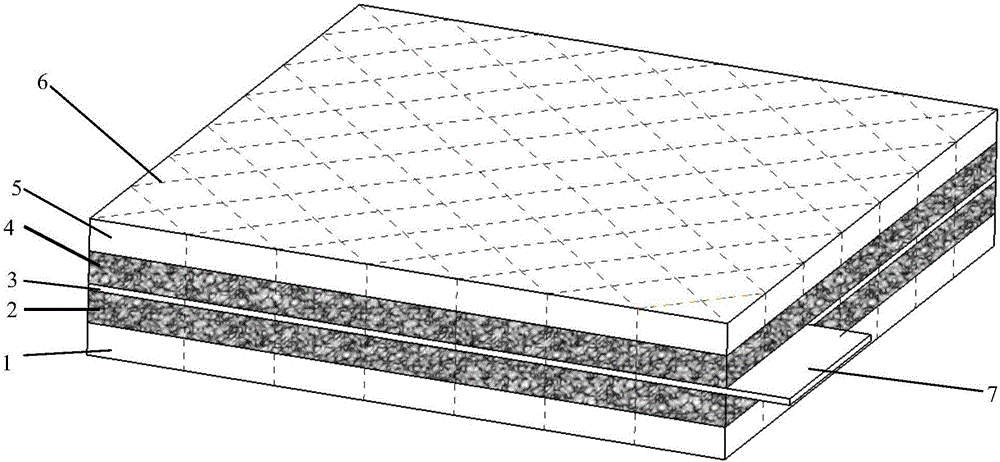

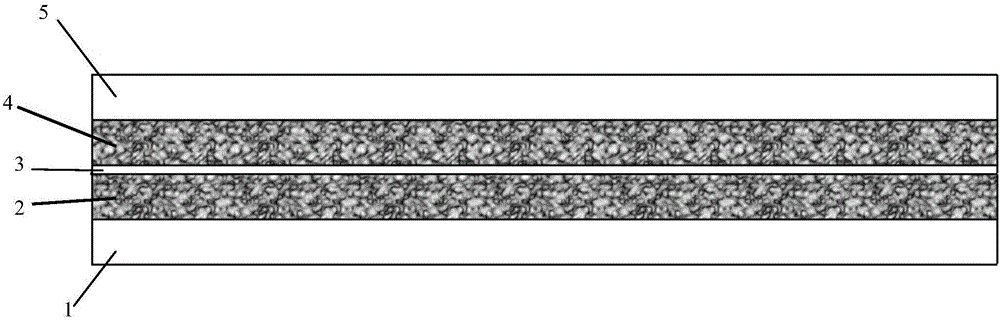

[0052] The structure diagram of carbon airgel electrode for capacitive deionization equipment is as follows figure 1 and figure 2 As shown, it is a stacked sandwich structure, which consists of the first spacer layer 1, the first carbon airgel layer 2, the current collector layer 3, the second carbon airgel layer 4, and the second spacer layer 5 from bottom to top. Laminated, the first non-woven fabric layer 1, the first carbon airgel layer 2, the current collector layer 3, the second carbon airgel layer 4, and the second mesh layer 5 are tightly stitched together by sutures 6 One.

[0053] The current collector layer 3 is provided with a tab protruding from the electrode at the edge, through which the external wire is connected. In this embodiment, the tab is long, 3 cm long and 1 cm wide.

[0054] The thickness of the first mesh separation layer or the second mesh separation layer is 0.2-0.5 mm. In this embodiment, a polypropylene non-woven fabric with a thickness of 0.5...

Embodiment 2

[0063] The carbon airgel particles are sieved successively with 50-mesh and 100-mesh sieves to obtain airgel particles with a particle size of 0.15-0.3 mm and a relatively uniform particle size distribution. Take 4g of carbon fibers with a wire diameter of 5um and a length of 1cm, mix them with 130g of airgel, place them in a stirrer and mix them evenly to prepare the airgel particle mixture. Use a polypropylene non-woven fabric with a length of 40 cm, a width of 40 cm, a thickness of 0.5 mm, and a filter hole diameter of 5 μm as the mesh layer. A carbon fiber cloth with a length of 40cm, a width of 40cm, and a thickness of 0.1mm is used as the current collector layer, and a fiber cloth tab with a length of 3cm and a width of 1cm protrudes from one corner of the carbon fiber cloth to facilitate the connection of wires.

[0064] First place the first mesh layer on the bottom, and then use a particle spreader to spread the carbon airgel particle mixture evenly on the first mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com