Device and method for recycling nitrogen and phosphorus from waste water of digestion tank

A technology for septic tanks and wastewater, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve problems such as difficult to realize simultaneous recycling of sewage sludge, single function, large nitrogen and phosphorus load in effluent, and improve water quality Treatment effect, low sludge yield, effect of reducing nitrogen and phosphorus treatment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

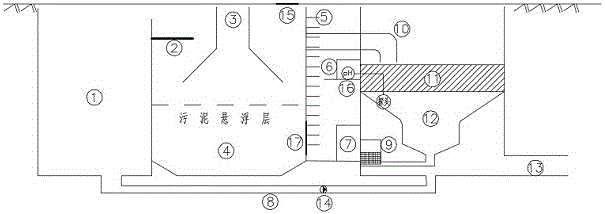

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] In the example of the present invention, such as figure 1 As shown, the waste water from the septic tank is collected into the system, and first flows into the pretreatment tank through the coarse filtration of the grid 2. Due to the anaerobic environment, methane and other gases are produced through reaction and fermentation, and rise along the wall of the gas chamber to reach the ground gas outlet 3. If It is useful and can be recycled. The sludge sinks to the sludge layer 4. Referring to the traditional septic tank, the cleaning cycle is set to 180 days, which can be adjusted appropriately according to the actual operation conditions. The sludge is discharged regularly to ensure the volume availability. When the sludge is discharged, the sludge is cleaned Mechanical cleaning is carried out at the opening, and the staff enters the mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com