Silicon carbide matrix composite and preparation method thereof

A composite material and silicon carbide-based technology, applied in the field of material science, can solve problems such as poor wear resistance and low hardness, and achieve the effects of low preparation cost, simple and easy-to-obtain raw materials, and good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

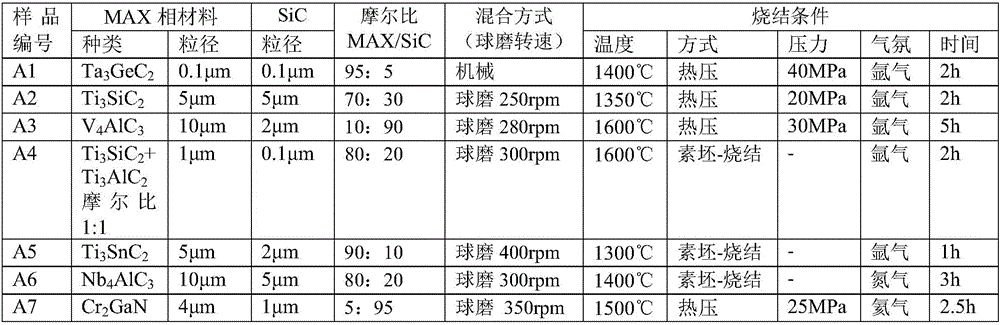

[0035] Mix the MAX phase material powder and SiC powder according to the raw materials, proportions and mixing methods in Table 1, and fill it into a graphite hot-pressing mold or a dry-pressing mold to obtain a disc-shaped green body. Under the sintering conditions in Table 1 After sintering and cooling to room temperature naturally, the obtained samples are respectively designated as samples A1-A7.

[0036] Table 1 Raw materials, proportions, mixing methods and sintering conditions

[0037]

Embodiment 2

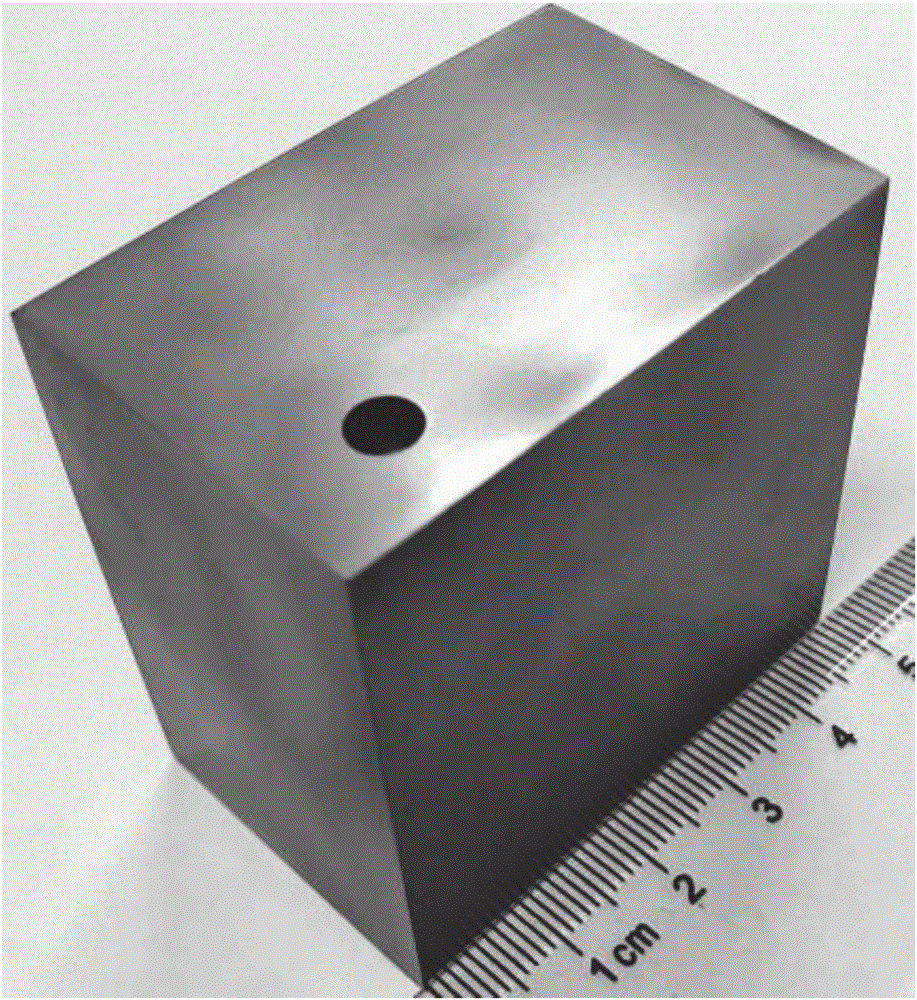

[0043] The samples A1-A7 obtained in Example 1 and the samples D1 and D2 obtained in Comparative Examples 1 and 2 were taken out and cut, and ground and polished to obtain gray cubic blocks. Test its Vickers hardness, see Table 2. Directly punch with electric drill press, the photo after the sample A1 punching that embodiment 1 obtains sees figure 1 , it can be seen that it has good machining performance, and the drilling surface is smooth and flat. The drilling results of samples A2 to A7 are the same as those of sample A1 figure 1 unanimous.

[0044]The sample D1 obtained in Comparative Example 1 can be directly drilled with an electric drill, but due to its low hardness, damage occurred during the drilling process, indicating that the hardness of the material obtained by sintering only MAX phase materials does not meet the requirements for machinability.

[0045] The sample D2 obtained in Comparative Example 2 suffered brittle cracks in the process of directly drilling w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com