Method for preparing foamed ceramics by surfactant hydrophobic modification of dispersant

A surfactant and hydrophobic modification technology, which is applied to ceramic products, other household utensils, household utensils, etc., to achieve the effects of wide applicability, high controllability of foam structure, and strong process practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Prepare ceramic slurry: use alumina powder with median particle size D50=450nm as raw material, use ultrapure water as solvent, use ammonium polyacrylate as dispersant, and the amount of dispersant added is 0.3wt. %, prepared by ball milling uniformly dispersed, solid content of 50vol.% ceramic slurry;

[0042] (2) Hydrophobic modified dispersant: add 0.05wt.% (relative to powder mass) dodecyltrimethylammonium chloride to the slurry, and continue ball milling for 20 minutes;

[0043] (3) Mechanical stirring and foaming: the above-mentioned ceramic slurry is mechanically stirred and foamed, the speed of the stirrer is 1000 rpm, and the mechanical stirring is foamed for 2 minutes;

[0044] (4) Curing and drying of the foam slurry: inject the above foam slurry into a porous metal mold lined with paper, place it at room temperature for 12 hours, demould, and then dry at room temperature for 48 hours;

[0045] (5) Sintering: heat the foamed ceramic green body at 1550°C ...

Embodiment 2

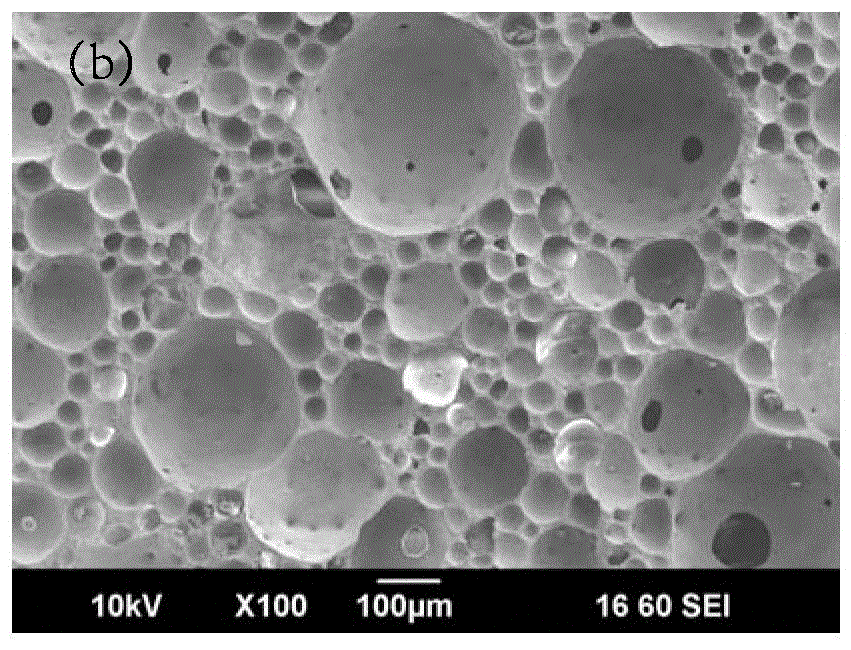

[0047] The preparation process is similar to Example 1, the difference is that 0.0375wt.% (relative to the powder mass) dodecyltrimethylammonium chloride is added to the slurry, and the slurry is placed at room temperature for 5 hours after pouring and then demolded. dry. The resulting alumina foam ceramics, such as Image 6 Shown in (b).

Embodiment 3

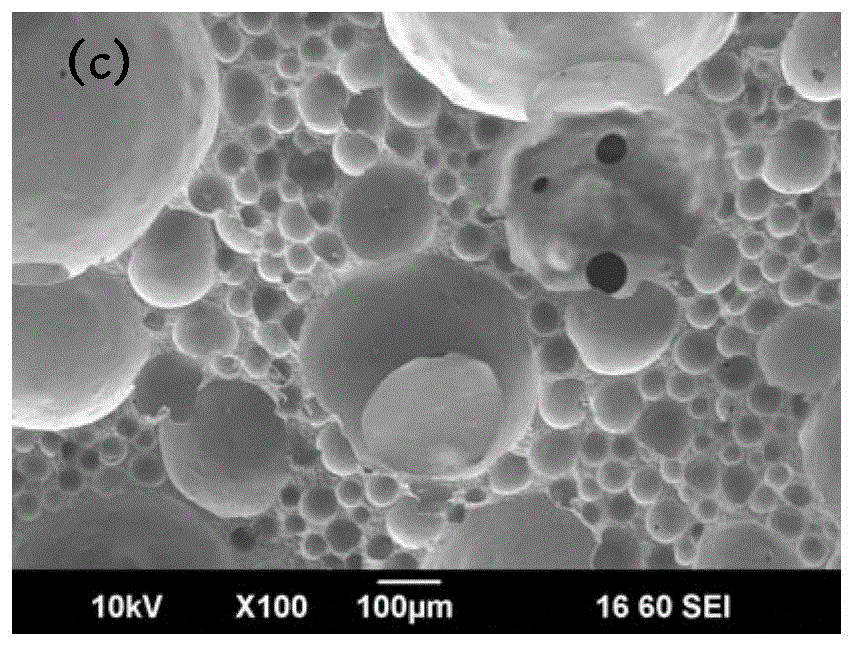

[0049] The preparation process is similar to that of Example 1, except that 0.025wt.% (relative to the powder mass) dodecyltrimethylammonium chloride is added to the slurry, and the slurry is placed at room temperature for 7 hours after pouring and then demolded. dry.

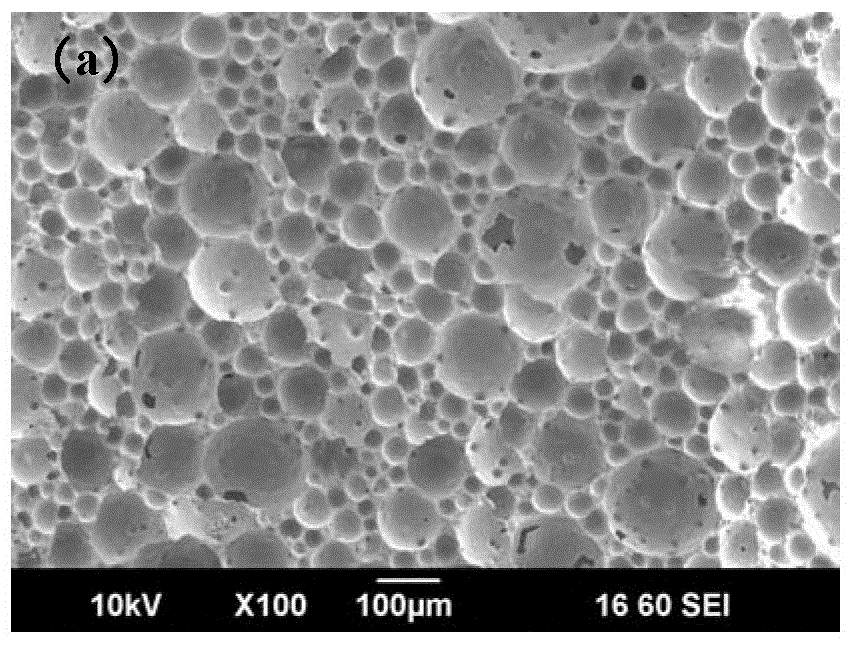

[0050] Fig. 1 (a), Fig. 1 (b), Fig. 1 (c) show respectively the microstructure figure that embodiment 1, embodiment 2, embodiment 3 prepare alumina foam ceramics, as can be seen, the prepared by this process The pore structure of alumina foam ceramics is complete and dense, and the pore size distribution of the pores becomes wider as the amount of surfactant decreases. The porosities of the foamed ceramics prepared in Examples 1-3 were 82%, 77%, and 76%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com