Preparation method of polydimethylsiloxane porous thin film

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of preparation of polydimethylsiloxane porous films, can solve the problems of limited materials, long preparation process time, soft mechanical strength, etc. Achieve good biocompatibility, improve the application range, and overcome the effect of long process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0022] Specific embodiment one, a kind of preparation method of polydimethylsiloxane porous film its steps are:

[0023] (1) Preparation of polydimethylsiloxane filler, adding curing agent and diluent to polydimethylsiloxane and stirring evenly to prepare polydimethylsiloxane filler, in which dimethyl The weight ratio of siloxane, curing agent and diluent is 1:1:1;

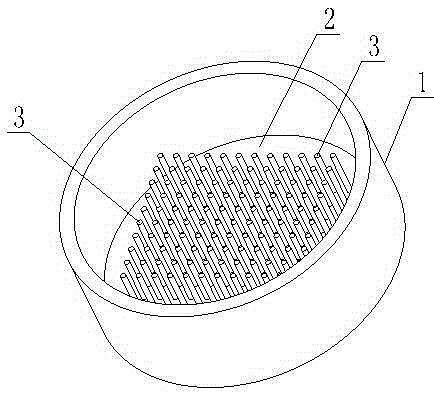

[0024] (2) Take the micro-flow hole mold 1, the bottom of the micro-flow hole mold groove 2 of the micro-flow hole mold 1 is provided with a plurality of through-hole columns 3, and the polydimethylsiloxane prepared in step (1) An alkane filler is added to the micro-flow hole mold groove 2 of the micro-flow hole mold 1, so that the polydimethylsiloxane filler is evenly distributed around the through-hole column 3;

[0025] (3) Next, the entire micro-fluid hole mold 1 was placed in an environment with a temperature of 50° C. for 4 hours to cure, and then cooled naturally at room temperature to prepare a polydimeth...

specific Embodiment 2

[0031] Specific embodiment two, a kind of preparation method of polydimethylsiloxane porous film its steps are:

[0032] (1) Preparation of polydimethylsiloxane filler, adding curing agent and diluent to polydimethylsiloxane and stirring evenly to prepare polydimethylsiloxane filler, in which dimethyl The weight ratio of siloxane, curing agent and diluent is 8:1:1;

[0033] (2) Take the micro-flow hole mold 1, the bottom of the micro-flow hole mold groove 2 of the micro-flow hole mold 1 is provided with a plurality of through-hole columns 3, and the polydimethylsiloxane prepared in step (1) An alkane filler is added to the micro-flow hole mold groove 2 of the micro-flow hole mold 1, so that the polydimethylsiloxane filler is evenly distributed around the through-hole column 3;

[0034] (3) Next, place the entire micro-fluid hole mold 1 in an environment with a temperature of 90° C. for 3 hours to solidify, and then cool naturally at room temperature to prepare a polydimethyls...

specific Embodiment 3

[0040] Specific embodiment three, a kind of preparation method of polydimethylsiloxane porous film its steps are:

[0041] (1) Preparation of polydimethylsiloxane filler, adding curing agent and diluent to polydimethylsiloxane and stirring evenly to prepare polydimethylsiloxane filler, in which dimethyl The weight ratio of siloxane, curing agent and diluent is 18:1:1;

[0042] (2) Take the micro-flow hole mold 1, the bottom of the micro-flow hole mold groove 2 of the micro-flow hole mold 1 is provided with a plurality of through-hole columns 3, and the polydimethylsiloxane prepared in step (1) An alkane filler is added to the micro-flow hole mold groove 2 of the micro-flow hole mold 1, so that the polydimethylsiloxane filler is evenly distributed around the through-hole column 3;

[0043] (3) Next, place the entire micro-fluid hole mold 1 in an environment with a temperature of 150° C. to cure for 1.5 hours, and then cool naturally at room temperature, thereby preparing a pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com