A kind of wampum leaf fermented beverage wine and its processing method

A technology of fermented beverage and processing method, which is applied in the field of utilization of yellow skin leaves, which can solve the problems of discarded leaves and insufficient utilization of yellow skin leaves, and achieve the effects of preventing the oxidation of flavor substances, excellent anti-oxidation quality, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Screening of yellow skin leaves: Screen the freshly picked yellow skin leaves. It is required to select yellow skin leaves with bright color and no pests. Do not mix dead leaves, moth-eaten leaves and pests. Use 1kg of yellow skin leaves that have been selected. Rinse with distilled water and set aside;

[0033] (2) Wampiped leaves beating: the Wampeded leaves screened in step (1) is beaten according to the feed-to-water mass ratio of 1:9, requiring the use of distilled water;

[0034] (3) Sugar content adjustment: put in white granulated sugar to make the concentration 210g / L;

[0035] (4) cellulase input: input cellulase to make its concentration 100ppm;

[0036] (5) pectinase input: drop in pectinase to make its concentration 50ppm;

[0037] (6) Yeast inoculation: drop in yeast so that its concentration is 200ppm;

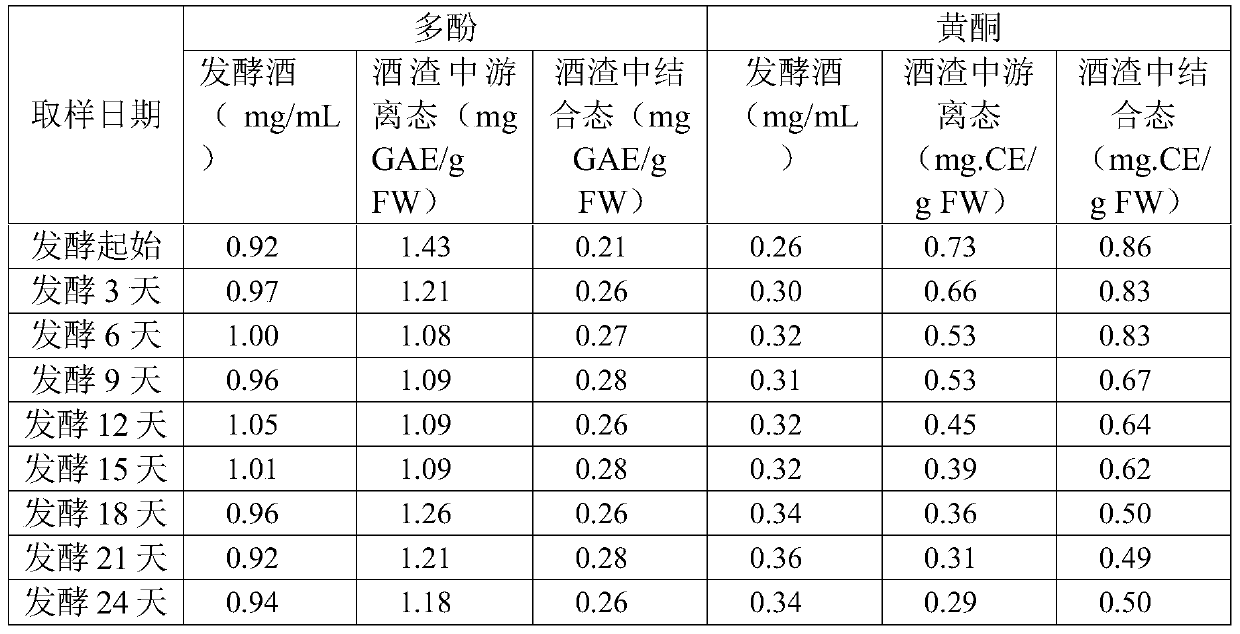

[0038] (7) Main fermentation: inject the prepared fermented liquid into the fermenter, which is 80% of the volume of the fermenter, and the main f...

Embodiment 2

[0051] (1) Screening of yellow skin leaves: Screen the freshly picked yellow skin leaves. It is required to select yellow skin leaves with bright color and no pests. Do not mix dead leaves, moth-eaten leaves and pests. Use 1kg of yellow skin leaves that have been selected. Rinse with distilled water and set aside;

[0052] (2) Wampiped leaves beating: the Wampeded leaves screened in step (1) are beaten according to the material-to-water mass ratio of 1:10, requiring the use of distilled water;

[0053] (3) Sugar content adjustment: put in white granulated sugar to make the concentration 210g / L;

[0054] (4) cellulase input: input cellulase to make its concentration 100ppm;

[0055] (5) pectinase input: drop in pectinase to make its concentration 50ppm;

[0056] (6) Yeast inoculation: drop in yeast so that its concentration is 200ppm;

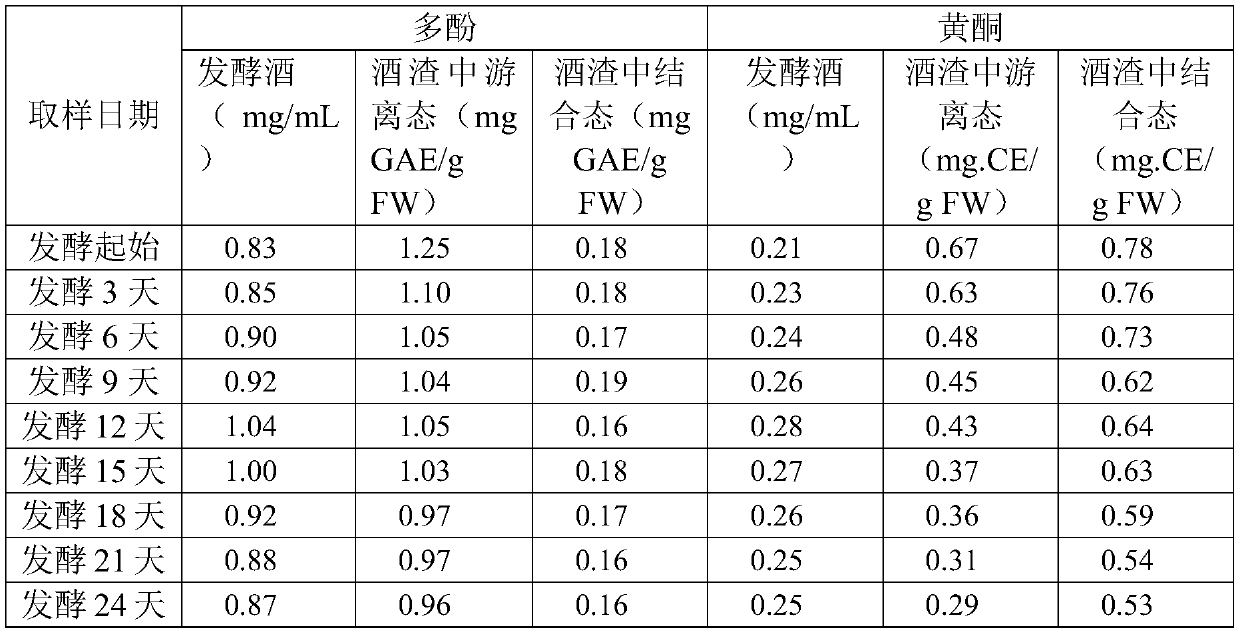

[0057] (7) Main fermentation: inject the prepared fermented liquid into the fermenter, which is 80% of the volume of the fermenter, and the ...

Embodiment 3

[0070] (1) Screening of yellow skin leaves: Screen the freshly picked yellow skin leaves. It is required to select yellow skin leaves with bright color and no pests. Do not mix dead leaves, moth-eaten leaves and pests. Use 1kg of yellow skin leaves that have been selected. Rinse with distilled water and set aside;

[0071] (2) Wampiped leaves beating: the Wampeded leaves screened in step (1) is beaten according to the feed-to-water mass ratio of 1:9, requiring the use of distilled water;

[0072] (3) Sugar content adjustment: put in white granulated sugar to make the concentration 210g / L;

[0073] (4) cellulase input: input cellulase to make its concentration 100ppm;

[0074] (5) pectinase input: drop in pectinase to make its concentration 50ppm;

[0075] (6) Yeast inoculation: drop in yeast so that its concentration is 200ppm;

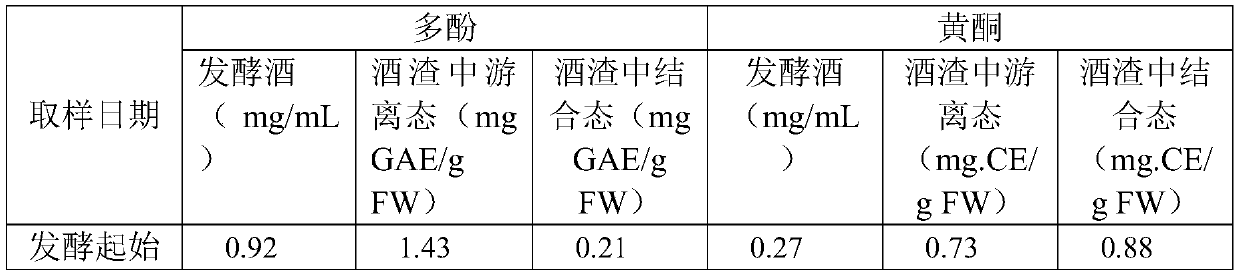

[0076] (7) Main fermentation: inject the prepared fermented liquid into the fermenter, which is 80% of the volume of the fermenter, and the main f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com