Acinetobacter junii for producing bio-surfactant and application of acinetobacter junii

A technology of Acinetobacter jelly, biological surface, applied in microorganism-based methods, microorganisms, microorganisms, etc., can solve the problem of no separation, etc., and achieve the effect of excellent emulsifying activity and ability to degrade saturated alkanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

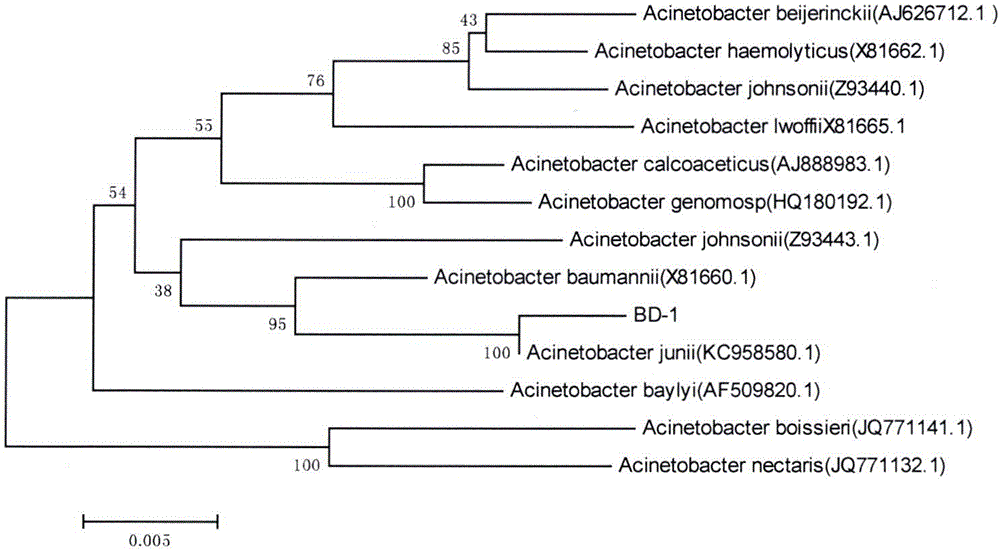

[0032] Embodiment 1, the separation, identification and preservation of the product surfactant bacterial classification of the present invention

[0033] 1. Isolation of bacteria producing biosurfactant

[0034] Among the present invention, the screening method of producing biosurfactant microorganisms is: take 10mL of the water sample collected from Xinjiang Oilfield and insert it into 100mL of sterilized crude oil inorganic salt culture medium (2% crude oil, v:v), 35 ℃ , 150rpm constant temperature shaking culture for 72h, select the experimental group with a high degree of emulsification and dispersion of crude oil, take 100μL of fermentation broth and spread it on the LB agar plate medium, and cultivate it at 35°C for 48h; pick single colonies of different shapes, and draw on the LB agar plate medium Line purification, cultured at 35°C for 48h. Pick a single colony and inoculate it into crude oil inorganic salt medium (g / L: NaNO 3 8. MgSO 4 0.5, KH 2 PO 4 1,K 2 HPO...

Embodiment 2

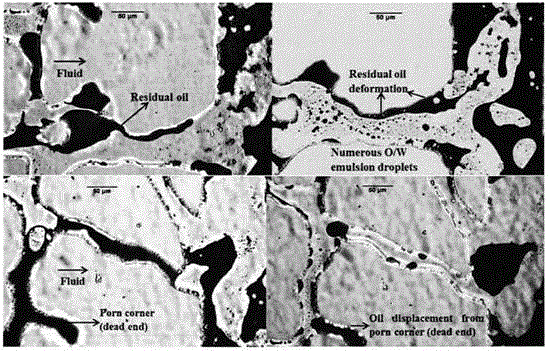

[0050] Embodiment 2, the degradation experiment of BD to crude oil

[0051] Seed bacterium liquid: Inoculate BD bacteria in the enrichment medium (prepared with reference to the prior art, the basic composition includes: Yeast 5g / L, NaCl 10g / L, Peptone 10g / L. Cultivate to a concentration of 10 8 -10 9 cells / mL, as the seed solution, for the experimental research of this example.

[0052] Crude oil inorganic salt medium (g / L): NaNO 3 8. MgSO 4 0.5, KH 2 PO 4 1,K 2 HPO 4 1. FeSO 4 ·7H 2 O0.02, Na 2 MoO 4 0.02, CaCl 2 2H 2 O 0.06, crude oil 0.5% (W / V), pH 7.2.

[0053] GC-MS analysis of crude oil degradation by BD bacteria:

[0054] Use LB medium to activate the strains, and then prepare crude oil inorganic salt medium (g / L): NaNO 3 8. MgSO 4 0.5, KH 2 PO 4 1,K 2 HPO 4 1. FeSO 4 ·7H 2 O 0.02, Na 2 MoO 4 0.02, CaCl 2 2H 2 O 0.06, Xinjiang crude oil 0.5% (W / V), pH 7.2, medium is subpackaged in the 250mL Erlenmeyer flask, every bottle 100mL, inocu...

Embodiment 3

[0059] Embodiment 3, product extraction and analysis of producing surfactant microorganism BD

[0060] Activation and fermentation of strains

[0061] (1) Strain activation: 100 μl of BD strain preserved in a glycerol tube was inoculated into LB medium, shaken and cultured in a constant temperature shaker at 37° C. for 8 hours, as a seed solution.

[0062] (2) Initial fermentation conditions: the seed solution is inserted into 200mL fermentation medium (the components of the fermentation medium are: sunflower oil 20g / L, NaNO 3 10g / L, KH 2 PO 4 0.8g / L, Na 2 HPO 4 0.8g / L, yeast 0.5g / L, pH 7.2), in a constant temperature shaker at 37°C, shake culture at 150r / min for 96h to obtain the initial fermentation broth.

[0063] Experiment 1. Purification of fermentation products

[0064] In the fermentation medium (the components of the fermentation medium are: sunflower oil 20g / L, NaNO 3 10g / L, KH 2 PO 4 0.8g / L, Na 2 HPO 4 0.8g / L, yeast 0.5g / L, pH 7.2) into 5% of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com