Lignocellulose simultaneous saccharification and fermentation process surfactant recovery technology

A technology of synchronous saccharification and fermentation and surfactants, applied in recycling technology, fermentation, plastic recycling, etc., can solve the problems of cellulase and Saccharomyces cerevisiae that cannot work normally, and achieve the effect of improving atom utilization and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

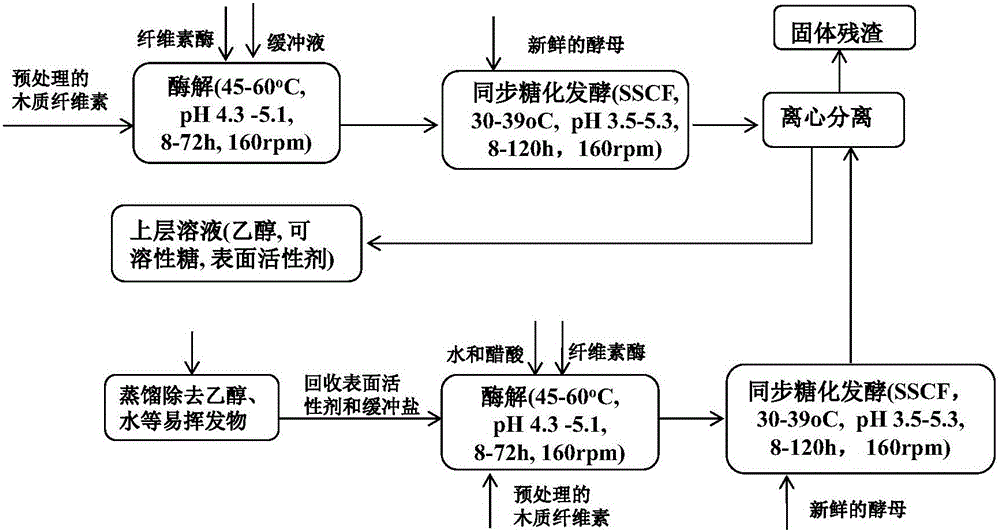

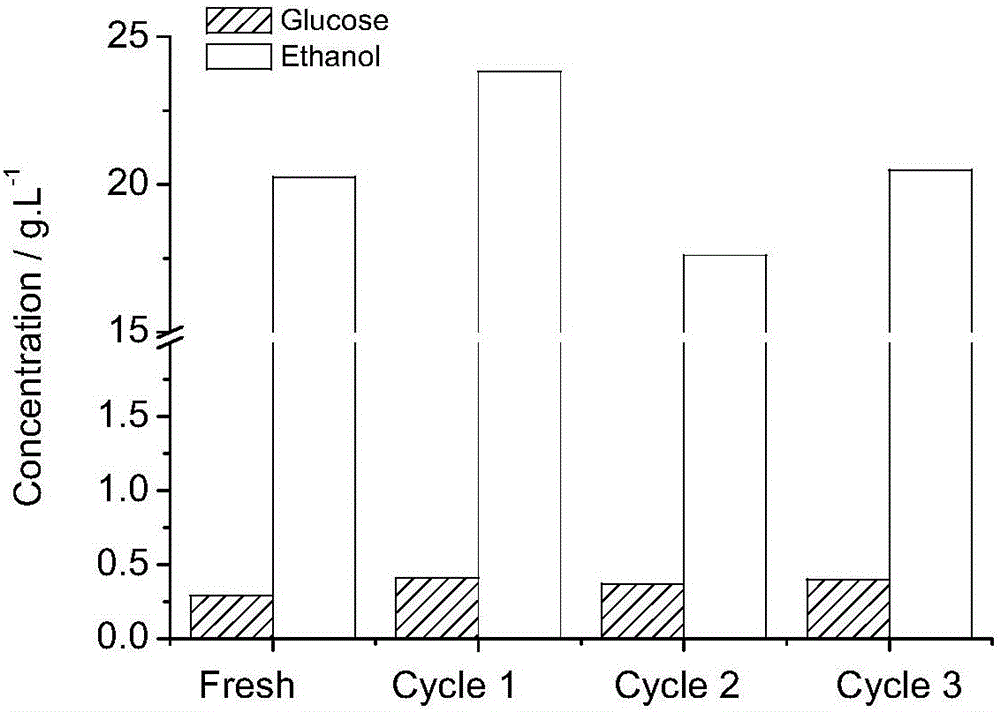

[0029] Mix 1.5g of pretreated fast-growing poplar powder as a substrate, 0.2g / ml PEG-1000, 12ml of buffer, cellulase 20FPU / g raw material, pre-enzymolyze at 50°C for 24 hours, and then lower the temperature to 33°C , and then add Saccharomyces cerevisiae to keep the cell concentration at 0.8*10 8 / mL for 72 hours of SSF fermentation. Carry out solid-liquid separation after fermentation, distill and extract the supernatant, and the remaining liquid after distillation is surfactant and buffer, which can be directly used in the next fermentation process (such as figure 1 ). PEG-1000 cycled 4 times the result is as follows figure 2 shown. It can be seen from the figure that PEG-1000 can be recycled and reused, and the concentration of ethanol is basically constant.

Embodiment 2

[0031] The experimental procedure is the same as that of Example 1, except that PEG-200 and ethanol concentration are shown in Table 1. It can be seen from the table that PEG-200 can be recycled and reused.

[0032] Table 1 Ethanol concentration data

[0033] PEG-200 Fresh cycle 1 cycle 2 cycle 3 Ethanol concentration [g / l] 17.0 18.25 16.20 15.08

Embodiment 3

[0035] The experimental procedure is the same as that of Example 1, except that 0.2 g / ml PEG-400 is added, and the concentration of ethanol is shown in Table 2. It can be seen from the table that PEG-400 can be recycled and reused.

[0036] Table 2 Ethanol concentration data

[0037] PEG-400 Fresh cycle 1 cycle 2 cycle 3 Ethanol concentration [g / l] 21.20 20.35 18.51 19.68

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com