A Method of Controlling Blast Furnace Gas Flow Distribution by Measuring Blast Furnace Ratio of Ratio of Raw Materials with Phased Array Radar

A phased array radar, blast furnace material surface technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of large amount of cloth, not very useful, and complicated forming process of cloth at one time, and achieve the effect of precise airflow adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through specific examples.

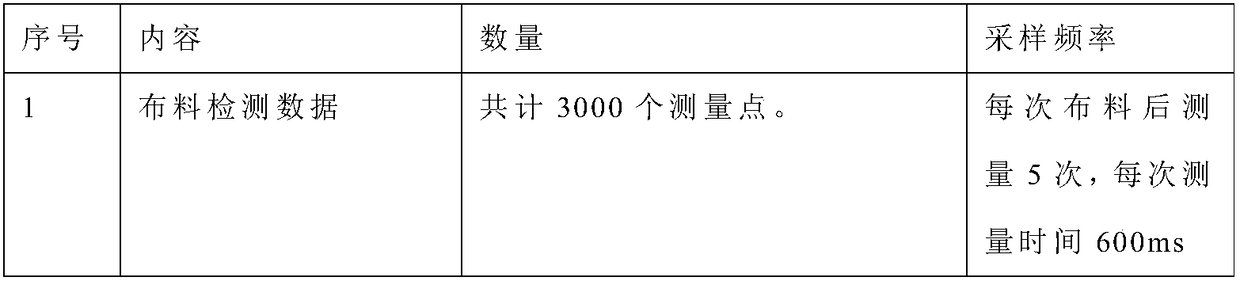

[0044] The method is implemented in an inner volume of 5000m 3 The blast furnace, the secondary machine of the blast furnace is equipped with two sets of Oracle database systems, using the C++ programming language, including four sets of PLC systems related to material distribution and coal injection control, two for material distribution control, and one for hearth furnace bottom detection and Control, one set is used for pulverized coal injection control, and one set of DCS system is used for the adjustment of blast parameters, etc., and two database systems are established.

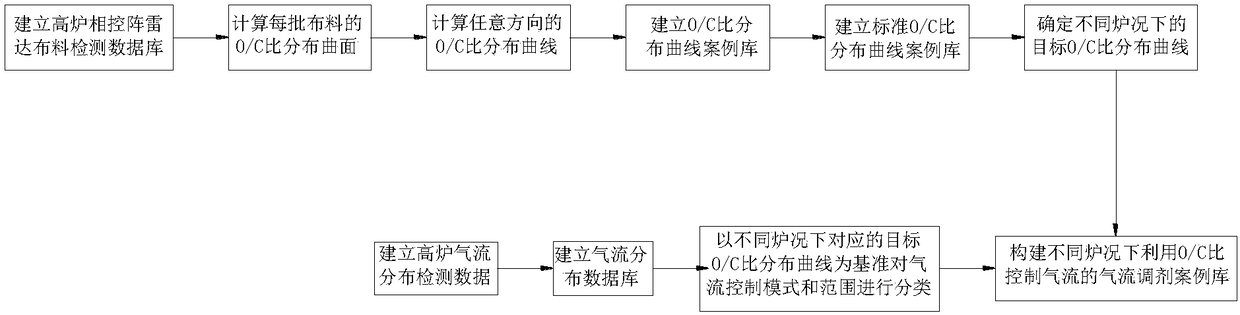

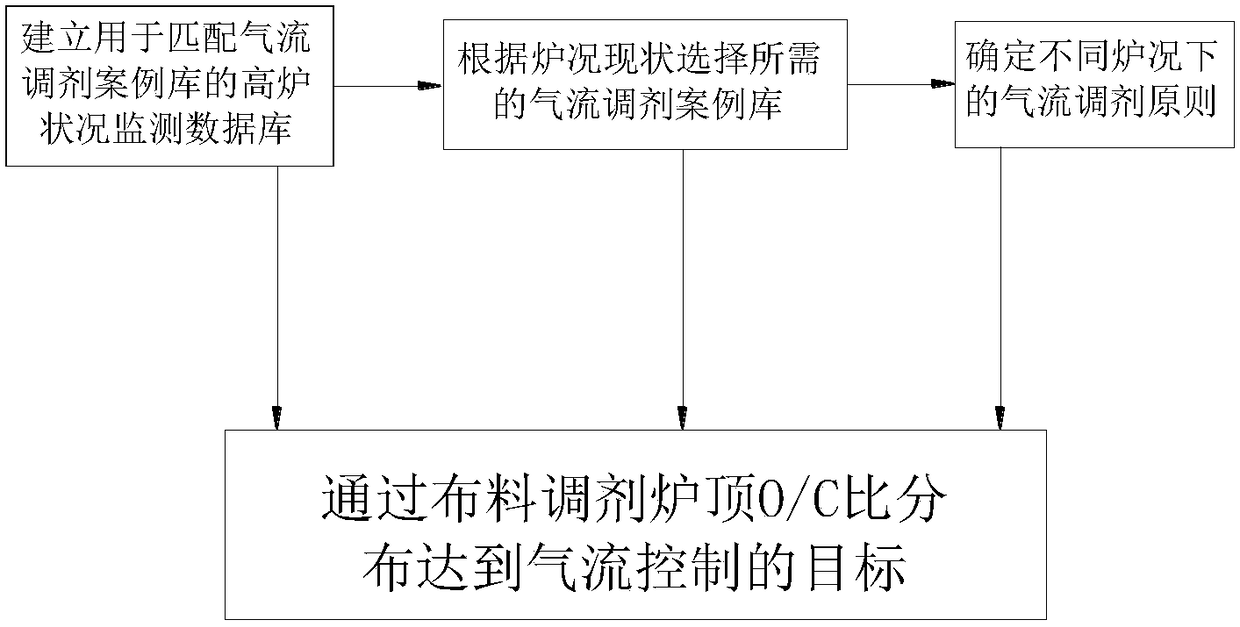

[0045] The method for controlling the gas flow distribution of the blast furnace by measuring the ore-coke ratio of the blast furnace charge surface with a phased array radar is as follows:

[0046] 1) Determine the target O / C ratio distribution curve under different furnace conditions and establish a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com