Colloidal-single-crystal-self-assembly computer simulation method based on heat-treatment assistance and preparing method of colloidal single crystals

A simulation method and self-assembly technology, applied in the direction of single crystal growth, self-gel state, chemical instruments and methods, etc., can solve problems such as difficulties, achieve the effect of improving quality and saving financial and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

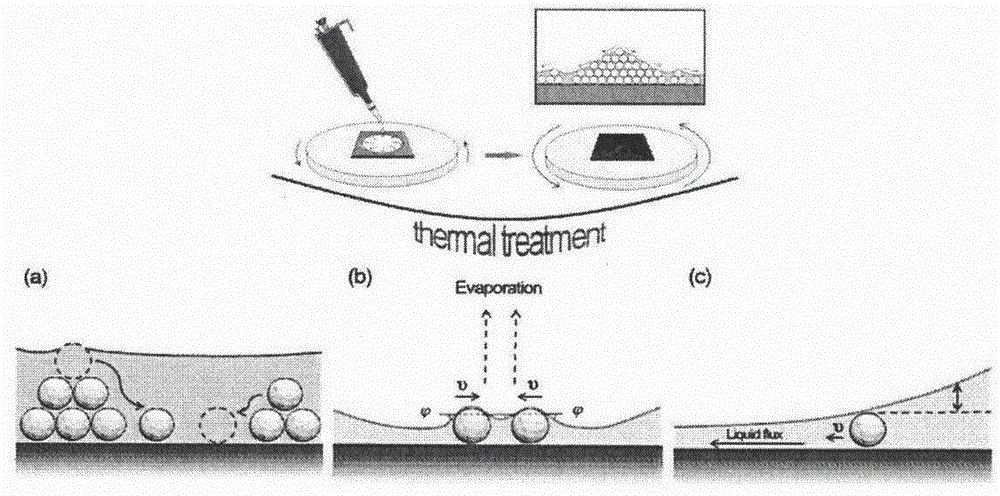

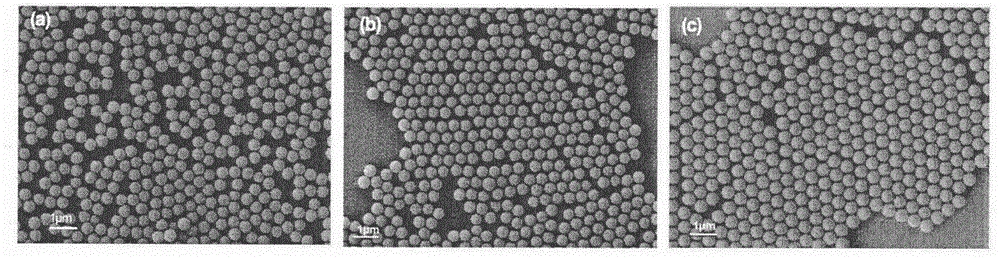

[0059] Example 1: Effects of different dispersion systems (ethanol, water, mixture of ethanol and ethylene glycol) on the assembly of monolayer colloidal crystals with polystyrene beads with a diameter of 460 nm.

[0060] (1) Clean the substrate according to the standard RCA procedure;

[0061] (2) Hydrophilic treatment of the cleaned substrate, putting it into a mixed solution of hydrogen peroxide and concentrated sulfuric acid;

[0062] (3) The preparation of glue concentration is 3% ethanol, water, the mixture of ethanol and ethylene glycol. Disperse polystyrene beads with a diameter of 460 nm in the three solvents

[0063] (4) Set the parameters of the glue homogenizer as: rotating speed (300 rpm) and glue homogenization time (6 seconds), put the substrate in the glue homogenizer and coat the glue film;

[0064] (5) Constant temperature treatment of the sample: the sample after homogenization is placed in a constant temperature device, and the temperature is controlled a...

Embodiment 2

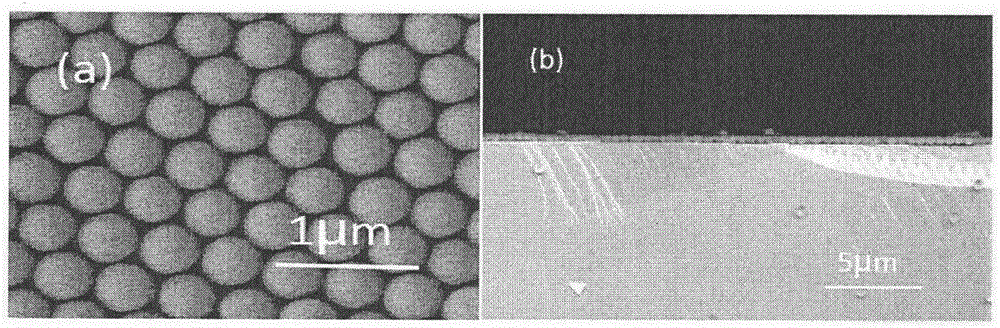

[0067] Example 2: Polystyrene beads with a diameter of 460 nm were assembled into a single-layer colloidal crystal.

[0068] (1) Clean the substrate according to the standard RCA procedure;

[0069] (2) Hydrophilic treatment of the cleaned substrate, putting it into a mixed solution of hydrogen peroxide and concentrated sulfuric acid;

[0070] (3) Prepare a mixed solution of ethanol and ethylene glycol, which is infiltrated with the substrate and the beads and is not volatile, and infiltrates the polystyrene beads with a diameter of 460nm to obtain a glue solution with a concentration of 10%;

[0071] (4) Monte Carlo simulation is carried out by computer to simulate a suitable self-assembly temperature. When simulating, first input the diameter of the ball R=460nm, U 0 =200, the energy no longer changes criterion δ=30. Then input different assembly temperatures T, and compare the simulation results by observation to find the best assembly temperature. The results show that...

Embodiment 3

[0075] Example 3: Polystyrene beads with a diameter of 460nm, the influence of glue concentration on the assembly of monolayer colloidal crystals.

[0076] (1) Clean the substrate according to the standard RCA procedure;

[0077] (2) Hydrophilic treatment of the cleaned substrate, putting it into a mixed solution of hydrogen peroxide and concentrated sulfuric acid;

[0078] (3) Prepare a mixed solution of ethanol and ethylene glycol with a glue concentration of 10%. Polystyrene beads with a diameter of 460nm are dispersed in this solvent, the liquid wets the substrate and the beads and does not volatilize easily.

[0079] (4) Parameter setting of glue homogenizer: rotating speed (300 rpm); glue homogenization time (6 seconds); glue concentration is 4%, 10%, 13% respectively, according to this parameter, put the substrate in the glue homogenizer Apply the glue solution film to obtain a uniform glue sample.

[0080] (6) The sample is placed in a constant temperature device. E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com