Quadrivalent chromium doped gallium oxide crystal and preparation method and application thereof

A technology of gallium oxide and tetravalent chromium, applied in the field of crystals and devices, can solve the problems of limited application range, low crystal thermal conductivity, inconvenient modulation, etc., and achieve the effect of stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

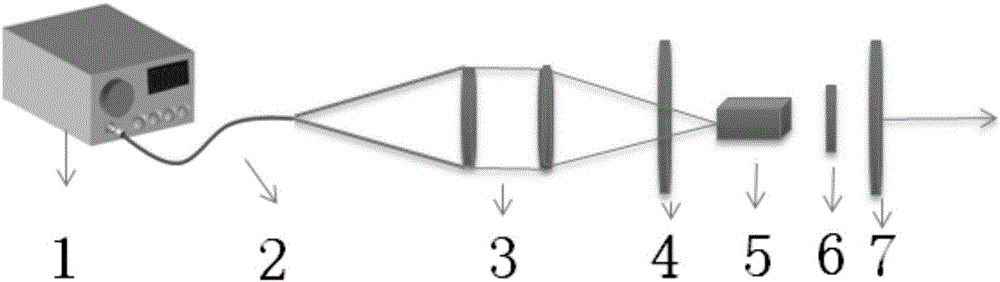

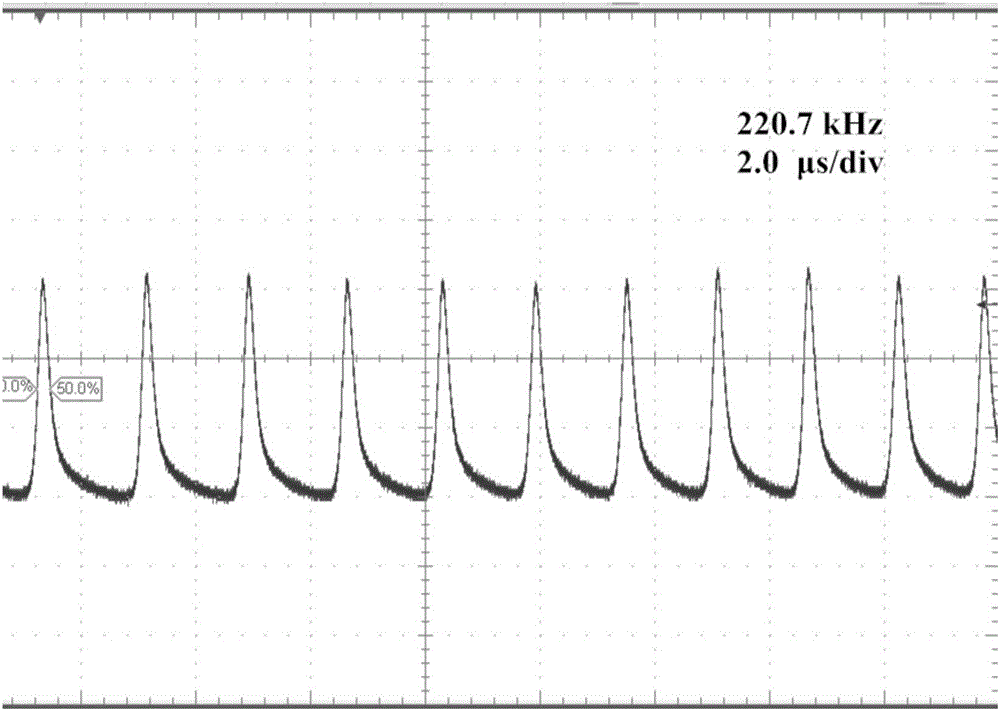

Method used

Image

Examples

Embodiment 1

[0033] x=0.01, y=0.02, the A position is Mg, and the crystal chemical formula of tetravalent chromium-doped gallium oxide is β-(Ga 0.97 Cr 0.01 Mg 0.02 ) 2 o 3 .

[0034] The preparation method of tetravalent chromium-doped gallium oxide crystal is as follows:

[0035] (1) Selection and processing of raw materials

[0036] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Cr 2 o 3 , MgO, put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 2 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then put the cake into a corundum crucible and sinter at 1400°C for 48 hours to obtain a chromium-magnesium double-doped gallium oxide polycrystalline material.

[0037] (2) Crystal growth

[0038] a. Put the pressed raw materials into the irid...

Embodiment 2

[0042] Example 2: x=0.02, y=0.05, the A position is Mg, and the chemical formula of tetravalent chromium-doped gallium oxide crystal is β-(Ga 0.93 Cr 0.02 Mg 0.05 ) 2 o 3 .

[0043] The preparation method of tetravalent chromium-doped gallium oxide crystal is as follows:

[0044] (1) Selection and processing of raw materials

[0045] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Cr 2 o 3 , MgO, put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 2 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then put the cake into a corundum crucible and sinter at 1400°C for 48 hours to obtain a chromium-magnesium double-doped gallium oxide polycrystalline material.

[0046] (2) Crystal growth

[0047] The difference from the step (2) in...

Embodiment 3

[0048] Example 3: x=0.02, y=0.02, the A position is Ca, and the crystal chemical formula of tetravalent chromium-doped gallium oxide is β-(Ga 0.96 Cr 0.02 Ca 0.02 ) 2 o 3 .

[0049] The preparation method of tetravalent chromium-doped gallium oxide crystal is as follows:

[0050] (1) Selection and processing of raw materials

[0051] Weigh Ga with a purity of 99.999% according to the stoichiometric ratio 2 o 3 、Cr 2 o 3 , CaO, put the raw materials into the mixer and mix them thoroughly for 48 hours. After the mixing is completed, the mixed raw materials are vacuum-dried at 100-200° C. for 2 hours to prevent absorbed water from entering the growth system, and the dried raw materials are pressed into a cake shape with a hydraulic press. Then put the cake into a corundum crucible and sinter at 1400° C. for 48 hours to obtain a chromium-calcium double-doped gallium oxide polycrystalline material.

[0052] (2) Crystal growth

[0053] a. Put the pressed raw materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com