A kind of preparation method of high-capacity lithium-ion battery hard carbon composite negative electrode material

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low discharge voltage, voltage hysteresis, and low initial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

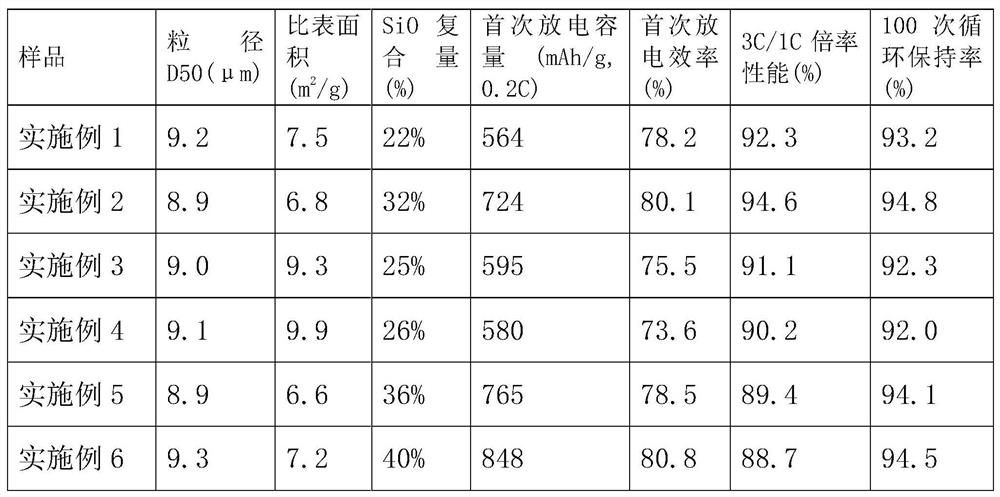

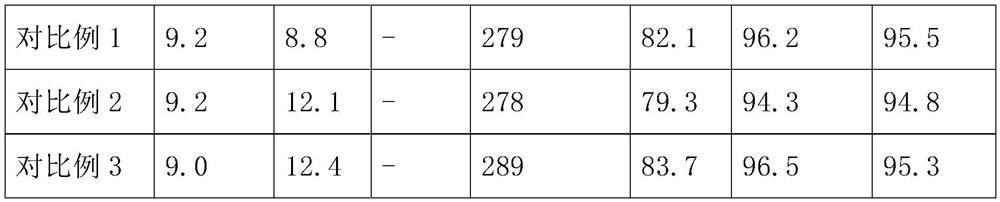

Examples

Embodiment 1

[0027] (1) Mixing of raw materials: Pulverize petroleum asphalt with a softening point of 120°C through a 100-mesh sieve, and uniformly mix 276g of silicon oxide with D50=3μm, 400g of paraformaldehyde and 2000g of petroleum asphalt powder in a high-speed mixing mixer , to obtain mixed powder;

[0028] (2), cross-linking polymerization reaction: then the mixed powder and 100 g of p-toluenesulfonic acid are fed into the reaction kettle, and under nitrogen protection and stirring conditions, the temperature is raised to 180 ° C for cross-linking polymerization reaction for 4h to obtain a cross-linked polymer. Of course in this step, the mixing of mixed powder and p-toluenesulfonic acid can also be completed together in the above-mentioned "raw material mixing" step;

[0029] (3), high temperature curing treatment: under the protection of nitrogen, the cross-linked polymer is heated to 300 ° C for curing treatment for 2 hours, then cooled to room temperature and discharged, the ob...

Embodiment 2

[0034] (1), mixing of raw materials: pulverize petroleum asphalt with a softening point of 120 ° C through a 100-mesh sieve, and uniformly mix 472 g, D50=3 μm silicon oxide, 600 g paraformaldehyde and 2000 g of the petroleum asphalt powder in a high-speed mixing mixer Mixing to obtain mixed powder;

[0035] (2), cross-linking polymerization reaction: then the mixed powder and 100 g of p-toluenesulfonic acid are fed into the reaction kettle, and under nitrogen protection and stirring conditions, the temperature is raised to 180 ° C for cross-linking polymerization reaction for 4h to obtain cross-linking polymerization. thing;

[0036] (3), high temperature curing treatment: under nitrogen protection, the cross-linked polymer is heated to 300 ° C for curing treatment for 2 hours, then cooled to room temperature and discharged, the obtained product is mechanically pulverized and passed through a 150-mesh sieve, and the material under the sieve is obtained. the first powder;

[...

Embodiment 3

[0041] (1) Mixing of raw materials: 2000g of thermoplastic phenolic resin powder with 8wt% urotropine, that is, hexamethylenetetramine and a softening point of 90°C, was premixed with D50 in a high-speed stirring mixer. = 425g of silicon oxide of 3 μm is uniformly mixed to obtain mixed powder;

[0042] (2), cross-linking polymerization reaction: put the mixed powder into the reaction kettle, and under nitrogen protection and stirring conditions, heat up to 150 ° C for cross-linking polymerization reaction for 4 hours to obtain a cross-linked polymer;

[0043] (3) High temperature curing treatment: under the protection of nitrogen, the cross-linked polymer is heated to 250 ° C for curing treatment for 2 hours, and then cooled to room temperature for discharging. the first powder;

[0044] (4) Pre-carbonization treatment: put the first powder into the pit furnace, heat it up to 550°C for 1 h under nitrogen protection, cool down to room temperature and discharge, adopt jet pulve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com