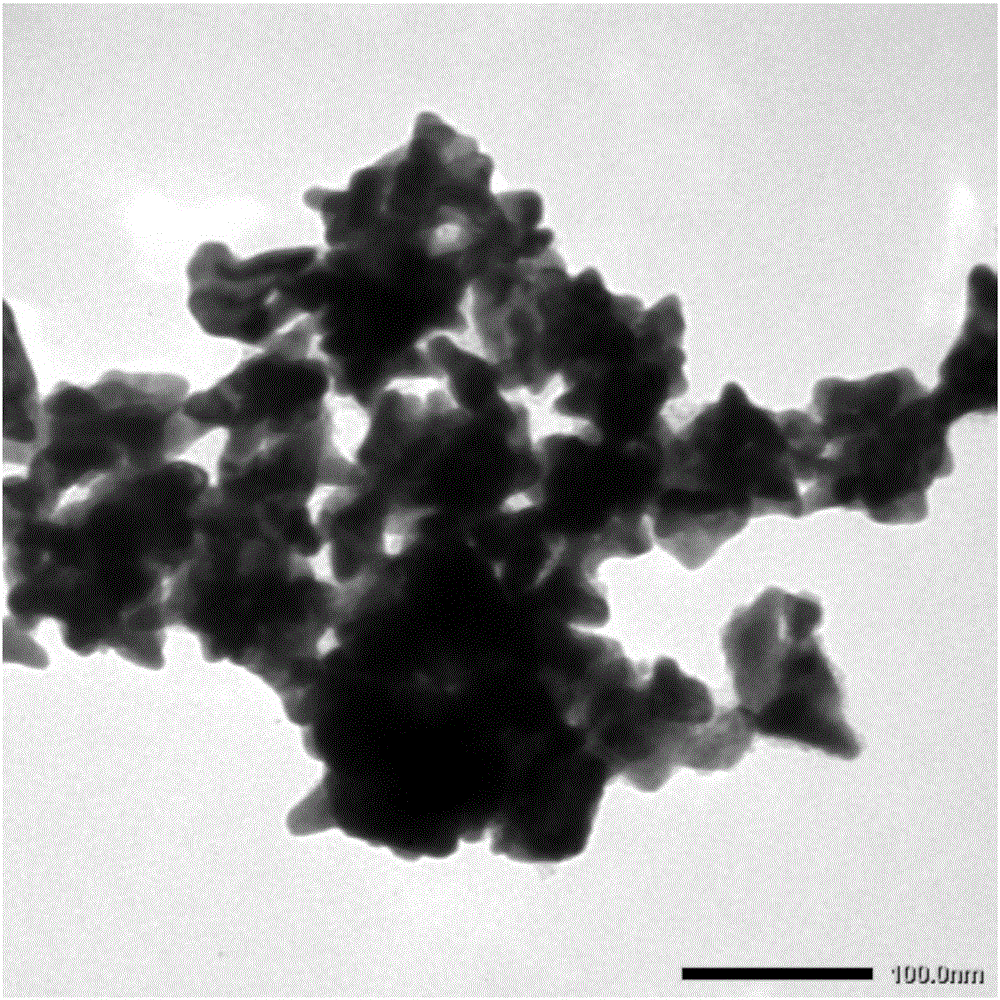

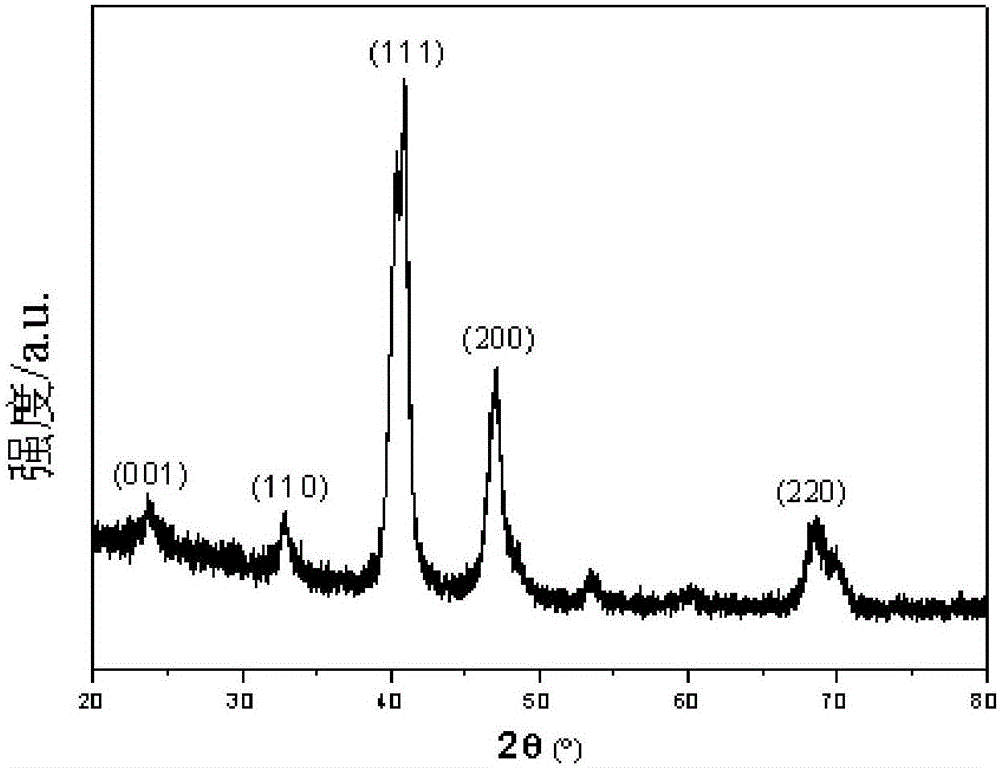

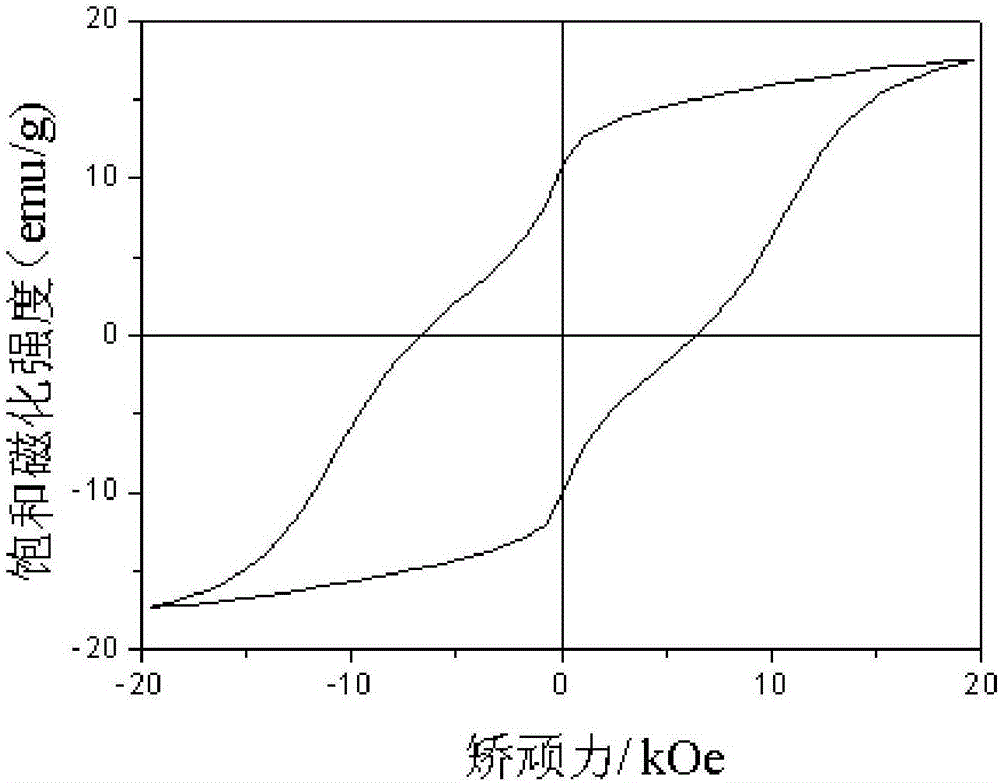

Method for preparing hard magnetism iron platinum (FePt) nanometer-particles by using inorganic salt as precursor

A nanoparticle and hard magnetic technology, applied in the field of preparing hard magnetic FePt nanoparticles, can solve the problems of complex preparation process of hard magnetic L10-FePt nanoparticles, irregular nanoparticle morphology, uncontrollable size, etc. Industrialized production, excellent magnetic properties, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment 1: This embodiment is a method for preparing hard magnetic iron-platinum nanoparticles using inorganic salt as a precursor, which is specifically carried out in the following steps:

[0027] 1. Mixing and stirring under protective gas: Add ferrous chloride, potassium chloroplatinate and oleylamine into a three-necked flask, and blow in nitrogen under the conditions of magnetic stirring and room temperature to exhaust air for 40 minutes to obtain a mixture; The ratio of the amount of iron and potassium chloroplatinate is 1: (1 to 1.2); the ratio of the amount of potassium chloroplatinate and oleylamine is 1: (150 to 160);

[0028] 2. Heating: The mixture prepared in step 1 is heated from room temperature to 200℃ at a heating rate of 5℃ / min~10℃ / min under the conditions of magnetic stirring and nitrogen protection, and then under magnetic stirring, nitrogen protection and the temperature is 200℃. Incubate at ℃ for 4h~5h; under the conditions of magnetic stir...

specific Embodiment approach 2

[0036] Specific embodiment two: this embodiment is different from specific embodiment one in that the ratio of the amount of ferrous chloride and potassium chloroplatinate described in step one is 1:1. Others are the same as the specific implementation.

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is different from specific embodiment one in that the ratio of the amount of potassium chloroplatinate and oleylamine mentioned in step one is 1:150. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com