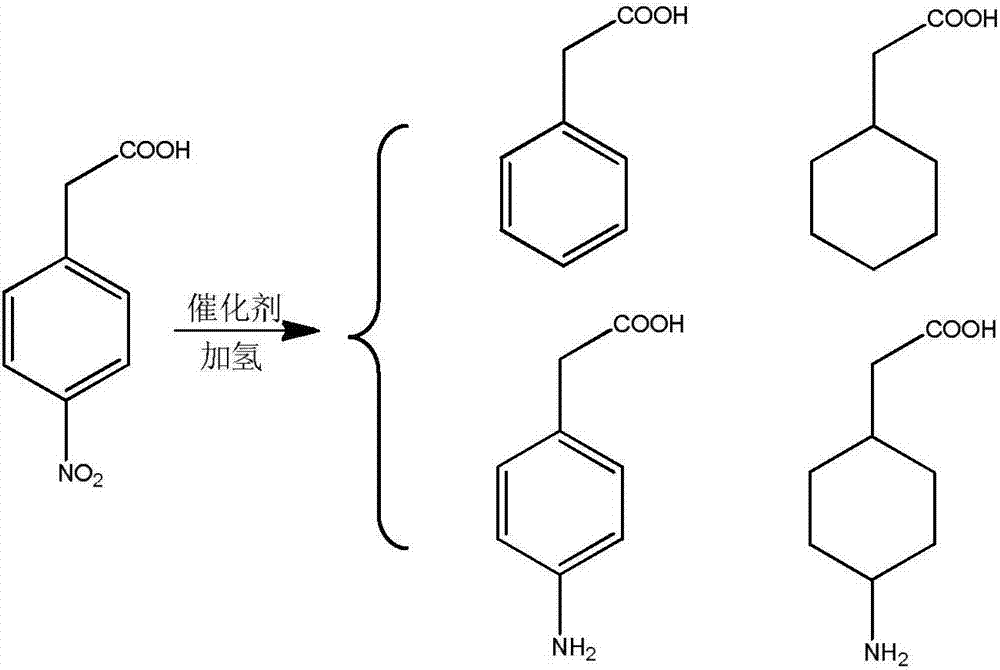

A kind of preparation method of 4-amino-cyclohexylacetic acid

A technology of nitrophenylacetic acid and amino, which is applied in the preparation of organic compounds, cyanide reaction preparation, chemical instruments and methods, etc., to achieve the effect of simple collection operation, low price, and favorable large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

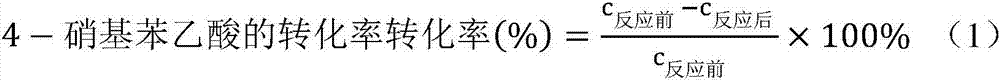

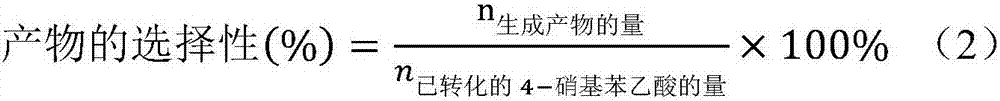

Method used

Image

Examples

preparation Embodiment 1

[0025] Preparation Example 1: Preparation of 3%Pd-5%Ni / C catalyst by deposition precipitation method

[0026] Take by weighing 155g palladium chloride (the content of metal palladium is 59.5wt%), 740g nickel nitrate hexahydrate adds 30kg deionized water, adds 2.760kg carrier gac, fully stirs, with the sodium hydroxide solution of 0.5wt% the previous step Adjust the pH of the slurry to about 7, and stir at room temperature for 18 hours. After the reaction, filter and wash the slurry until the filtrate becomes neutral and free of chloride ions. Add 20 kg of deionized water to the washed filter cake, add 1.5 L of formaldehyde, and set the temperature at 50 ° C. After reacting for 2 hours, the active component metal is reduced to obtain a 3%Pd-5%Ni / C catalyst.

preparation Embodiment 2

[0027]Preparation Example 2: Preparation of 3%Pd-3%Ru / C catalyst by deposition precipitation method

[0028] Take by weighing 155g palladium chloride (the content of metal palladium is 59.5wt%) and 250g ruthenium chloride (the content of metal ruthenium is 37.5wt%), add 30kg deionized water after dissolving with 2L 15wt% sodium chloride solution, add 3kg carrier activated carbon, fully stirred, adjust the pH of the slurry in the previous step to about 8 with 10wt% sodium bicarbonate solution, stir in a water bath at 30°C for 1 hour, after the reaction, filter and wash the slurry until the filtrate is neutral and chlorine-free ions, add 20kg of deionized water to the washed filter cake, add 2.5L of formaldehyde, react at 50°C for 1h, and reduce the active component metal palladium to obtain a 3%Pd-3%Ru / C catalyst.

preparation Embodiment 3

[0029] Preparation Example 3: Preparation of 2%Au-3%Pd / C Catalyst by Deposition and Precipitation Method

[0030] Take by weighing 90g gold chloride (the content of metal gold is 47.8wt%), 155g palladium chloride (the content of metal palladium is 59.5wt%), add after dissolving with 1000kg deionized water, add 1.9kg carrier gac, fully stir, Use 10wt% sodium bicarbonate solution to adjust the pH of the slurry in the previous step to about 7, stir in a water bath at 80°C for 2h, filter, wash until there are no chloride ions, dry, and reduce with hydrogen, and reduce at 300°C for 3h to obtain 2%Au-3%Pd / C catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com