Guar gum fracturing fluid nano crosslinking agent with good temperature resistance and preparation method thereof

A guar gum fracturing fluid, temperature-resistant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of application limitation, viscosity drop, low cross-linking efficiency, etc., and achieve effective and economical fracturing construction , the network structure is huge and the effect of increasing the size of the crosslink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a temperature-resistant guar gum fracturing fluid nano-crosslinking agent, comprising the following steps: adding 4 g of titanium tetrachloride to 100 mL of absolute ethanol, heating up to 40° C., stirring at a constant speed of 300 rpm for 0.5 h, Add 5 g of γ-aminopropyltriethoxysilane, then raise the temperature to 70°C, stir at a constant speed of 200 rpm for 2.5 h, raise the temperature to 80°C, continue stirring for 1 h, and cool to room temperature to obtain light yellow transparent guar gum Fracturing fluid nano-crosslinking agent.

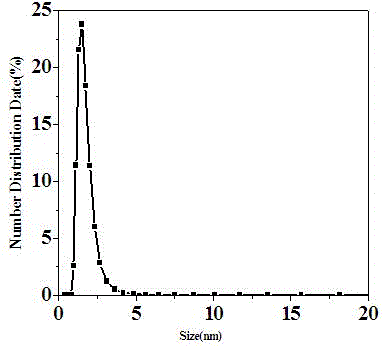

[0022] like figure 1 As shown, the particle size of the nano-crosslinking agent prepared above was measured by a laser particle size tester to be about 2 nanometers.

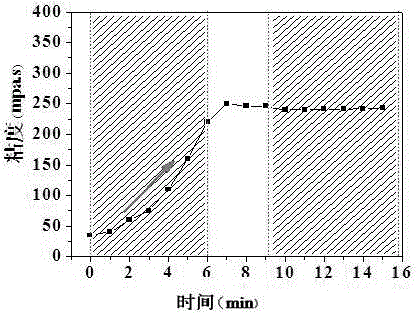

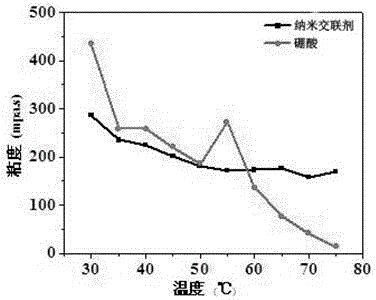

[0023] Take 1 mL of the nano-crosslinking agent prepared above and add it to 100 mL of 0.3% guar gum solution and stir, as figure 2 As shown, the nano-crosslinking agent prepared above has a 6-min delayed cross-linking interval when used, and...

Embodiment 2

[0029] A preparation method of temperature-resistant guar gum fracturing fluid nano-crosslinking agent, comprising the following steps: adding 2 g of titanium tetrachloride to a mixed solution of 30 mL of absolute ethanol and 50 mL of glycerol, heating up to 40 ° C, Stir at a constant speed of 300 rpm for 0.5 h, add 4 g of γ-aminopropyltrimethoxysilane, then raise the temperature to 80°C, stir at a constant speed of 200 rpm for 4 h, and cool to room temperature to obtain light yellow transparent guar gum fracturing fluid nano crosslinking agent.

[0030] Take 1 mL of the nano-crosslinking agent prepared in Example 2 and add it to 100 mL of guar gum solution with a mass fraction of 0.3% and stir to compare the state of the guar gum solution at the initial stage of crosslinking and the state of the late stage of crosslinking. The performance is good, and the cross-linking effect is obvious. Take 100 mL of guar gum solution, add 20-40 mesh standard ceramsite, stir evenly, then a...

Embodiment 3

[0032] A preparation method of a temperature-resistant guar gum fracturing fluid nano-crosslinking agent, comprising the following steps: adding 4 g of titanium tetrachloride to a mixed solution of 50 mL of absolute ethanol and 50 mL of isopropanol, heating up to 40 ° C, Stir at a constant speed of 300 rpm for 0.5 h, add 5 g of N-aminoethyl-γ-aminopropyltrimethoxysilane, then raise the temperature to 70°C, stir at a constant speed of 200 rpm for 4 h, raise the temperature to 90°C, and continue stirring for 2 h, After cooling to room temperature, a light yellow transparent guar gum fracturing fluid nano-crosslinking agent is obtained.

[0033] Take 1 mL of the nano-crosslinking agent prepared in Example 3 and add it to 100 mL of guar gum solution with a mass fraction of 0.3% and stir to compare the state of the guar gum solution at the initial stage of crosslinking and the state of the late stage of crosslinking. The performance is good, and the cross-linking effect is obvious....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com