Preparation method of metal nanoscale sieve based on polymer

A technology of metal nano and polymer, applied in the direction of nanotechnology, electroforming nanostructure, electroforming, etc., can solve the problem of non-reusable alumina template, and achieve the effect of low cost, simple process and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

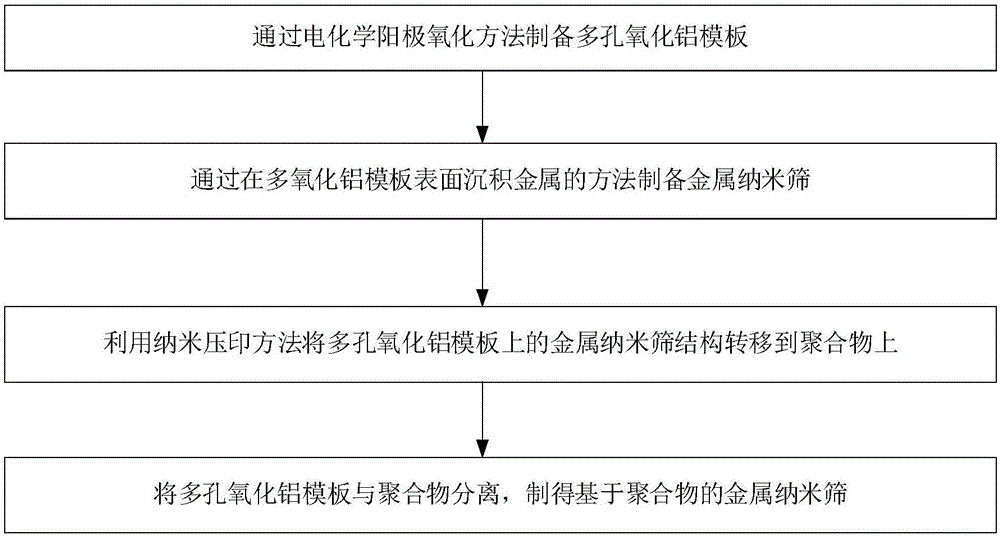

[0034] Such as figure 1 Shown, the flowchart of the polymer-based metal nanosieve preparation method provided by the present invention includes the following steps:

[0035] (1) Prepare porous alumina templates by electrochemical anodic oxidation;

[0036] (2) Metal nanosieves are prepared by depositing metal on the surface of the multi-alumina template;

[0037] (3) transfer the metal nanosieve structure on the porous alumina template to the polymer by nanoimprinting method;

[0038] (4) The porous alumina template is separated from the polymer to prepare a polymer-based metal nanosieve.

[0039] The method provided by the invention has simple process, low cost, and can be used for large-scale manufacturing, and the nanoimprinting method can be used to completely transfer the metal nanosieve structure to the polymer, so that the polymer-based metal nano Excellent sieve performance.

no. 1 example

[0040] The first embodiment of the polymer-based metal nanosieve preparation method provided by the present invention comprises the following steps:

[0041] (1) Prepare a porous alumina template by an electrochemical anodic oxidation method, including the following steps:

[0042] (11) Put the aluminum foil with a purity of more than 99.99% into 0.3mol / L oxalic acid solution for the first anodic oxidation, the oxidation voltage is 40V, the oxidation temperature is 5°C, and the oxidation time is 4h;

[0043] (12) Soak the aluminum foil after the first step of anodic oxidation in a mixture of 6wt% phosphoric acid and 1.8wt% chromic acid for 8h at a temperature of 60°C;

[0044] (13) Put the aluminum foil soaked in the mixed solution into 0.3mol / L oxalic acid solution for the second step of anodic oxidation, the oxidation voltage is 40V, the oxidation temperature is 5°C, and the oxidation time is 30min;

[0045] (14) Expand the aluminum foil after the second step of anodic oxid...

no. 2 example

[0056] The second embodiment of the polymer-based metal nanosieve preparation method provided by the present invention includes the following steps:

[0057] (1) Preparation of porous alumina template by electrochemical anodic oxidation method:

[0058] (11) Put the aluminum foil with a purity of more than 99.99% into 0.3mol / L oxalic acid solution for the first anodic secondary oxidation, the oxidation voltage is 40V, the oxidation temperature is 3°C, and the oxidation time is 8h;

[0059] (12) Soak the aluminum foil after the first step of anodic oxidation in a mixture of 6wt% phosphoric acid and 1.8wt% chromic acid for 12h at a temperature of 60°C;

[0060] (13) Put the aluminum foil soaked in the mixed solution into 0.3mol / L oxalic acid solution for the second anodic oxidation, the oxidation voltage is 40V, the oxidation temperature is 3°C, and the oxidation time is 50min;

[0061] (14) The aluminum foil after the second step of anodic oxidation was placed in a 5wt% phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com