Synthetic method for natural product 2,3',4,5'-tetrahydroxy bibenzyl

A technology of natural products and synthetic methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of unrecyclable catalysts, poor atom economy, high cost, etc. Economical and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

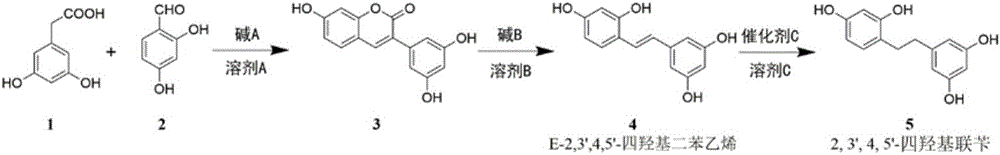

Method used

Image

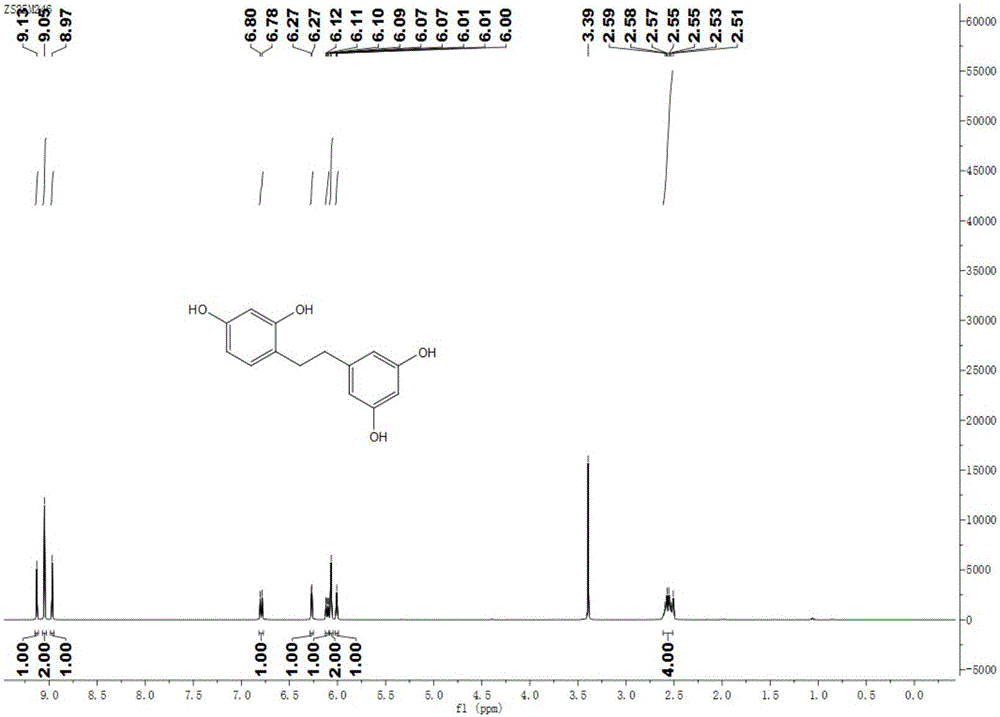

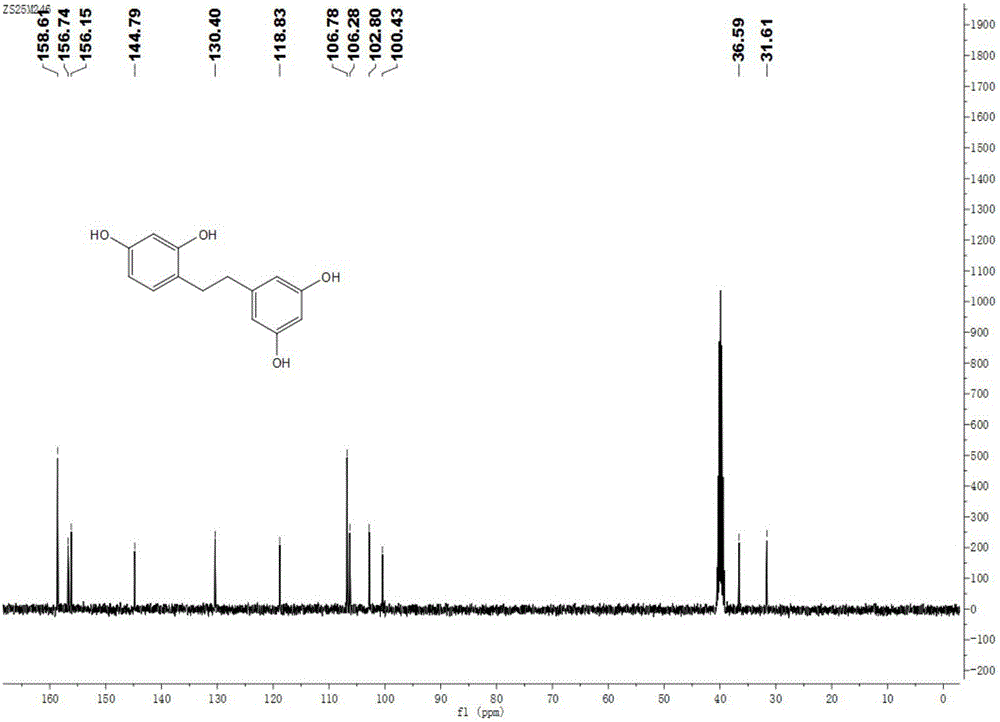

Examples

Embodiment 1

[0029] (1) Preparation of 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin

[0030] To a round bottom flask was added 3,5-dihydroxyphenylacetic acid (2.52 g, 15 mmol), 2,4-dihydroxybenzaldehyde (2.07 g, 15 mmol), triethylamine (4.55 g, 45 mmol), acetic anhydride (10 mL ), stirred, heated to 110° C. in an oil bath, and reacted for 7 hours. After the reaction is complete, pour the reaction solution into 50 mL of ice water while it is hot, stir, and solids precipitate out, filter with suction, wash the filter cake with water, collect the filter cake, dissolve the filter cake with aqueous sodium hydroxide solution, wash with ethyl acetate, and acidify with hydrochloric acid When pH=3~4, a solid is precipitated, suction filtered, washed with water, the filter cake is collected, dried to obtain a light yellow solid, which is 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin, weight 3.24g , yield 80%.

[0031] (2) Preparation of E-2,3',4,5'-tetrahydroxystilbene

[0032] Put 3-(3,5-dihydroxypheny...

Embodiment 2

[0036] (1) Preparation of 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin

[0037] To a round bottom flask was added 3,5-dihydroxyphenylacetic acid (2.52 g, 15 mmol), 2,4-dihydroxybenzaldehyde (2.07 g, 15 mmol), triethylamine (4.55 g, 45 mmol), propionic anhydride (10 mL ), stirred, heated to 110° C. in an oil bath, and reacted for 7 hours. After the reaction is complete, pour the reaction solution into 50 mL of ice water while it is hot, stir, and solids precipitate out, filter with suction, wash the filter cake with water, collect the filter cake, dissolve the filter cake with aqueous sodium hydroxide solution, wash with ethyl acetate, and acidify with hydrochloric acid When pH=3~4, a solid is precipitated, suction filtered, washed with water, the filter cake is collected, dried to obtain a light yellow solid, which is 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin, weight 2.75g , yield 68%.

[0038] (2) Preparation of E-2,3',4,5'-tetrahydroxystilbene

[0039] Put 3-(3,5-dihydroxyph...

Embodiment 3

[0043] (1) Preparation of 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin

[0044] To a round bottom flask was added 3,5-dihydroxyphenylacetic acid (2.52 g, 15 mmol), 2,4-dihydroxybenzaldehyde (2.07 g, 15 mmol), triethylamine (4.55 g, 45 mmol), acetic anhydride (10 mL ), stirred, heated to 110° C. in an oil bath, and reacted for 9 hours. After the reaction is complete, pour the reaction solution into 50 mL of ice water while it is hot, stir, and solids precipitate out, filter with suction, wash the filter cake with water, collect the filter cake, dissolve the filter cake with aqueous sodium hydroxide solution, wash with ethyl acetate, and acidify with hydrochloric acid When pH=3~4, a solid is precipitated, suction filtered, washed with water, the filter cake is collected, dried to obtain a light yellow solid, which is 3-(3,5-dihydroxyphenyl)-7-hydroxycoumarin, weight 2.87g , yield 71%.

[0045] (2) Preparation of E-2,3',4,5'-tetrahydroxystilbene

[0046] Put 3-(3,5-dihydroxypheny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com